Displaying items by tag: UK Sailmakers Ireland

Winter Sails Service From UK Sailmakers Ireland

The Winter period is the best time for getting your sails serviced writes Barry Hayes of UK Sailmakers Ireland.

Whether it’s your car, your own health, or your sails, it is no secret that an annual check-up and service is the best way to protect your investment and avoid trouble down the line.

Our sail loft in Crosshaven, Co Cork, has been a sail service centre for over forty years. Thousands of sails have been on our floor and it’s not often we see something we haven’t encountered before. We can spot issues before they emerge as serious problems. This will not only save you money – but also time. No one wants their sails on our floor when they should be on your boat out sailing!

Depending on the type of sailing you are doing an ‘annual service’ can consist of many different things. Some of you may even ask “do I really need to?” The short answer is –yes you do – let me explain why.

"It is no secret that an annual check-up and service is the best way to protect your investment"

Club Racer

If you’re a club racer then you’re the most likely to be asking the “do I really need to?” question. In fact, your sails will likely benefit more than anyone else from a good annual service.

When we receive your sails in our loft we give them a full check over. We check all luff tapes for tears, check common wear spots such as where it interacts with spreaders and stanchions, check for missing tell tails, and identify if there are any unknown causes for the problem which is presenting itself on the floor.

For example; we see many luff tape repairs throughout the season and during winter service. Luff tapes don’t just tear. If they tear then there is a reason why. Sometimes it can be a simple mistake of sheeting on too early or skipping the feeder – but often there is a problem which can be solved on the boat. We discuss potential issues with our customers and present solutions to avoid damage occurring in the future.

While we have your sails we can re-measure them for IRC. This can lead to a nice reduction in your IRC handicap upon your revalidation for the 2020 season.

Our expert staff pick up details which the untrained eye would overlook. Leverage this experience to protect your investment and maximize your time on the water come next spring.

Coastal Cruiser

If cruising or day sailing is your thing then you likely have a UV strip on your headsail and plenty of covers, sprayhoods, dodgers etc.

One of the worst things you can do for your sails is to leave them on your boat for a prolonged period of time – even during the sailing season. If you are not going to be using your boat for a month or more then take down the sails and store them aboard. If you only wear your good flamingo shirt to weddings, and you don’t have one for two months, you aren’t going to leave it hanging on the line!

Exposure to the sun degrades your sails and covers – this is simply a fact of life. The UV light breaks down the fabric and especially the stitching. During an annual check-up, we inspect your entire UV cover and its stitching. A quick run through a sewing machine now is much more cost-effective than having to replace an entire torn UV strip after an Irish winter storm. The same goes for your covers. Deliver them all to us together for a full assessment.

Storage

When you are packing your boat up for the season you should also be thinking about where you are going to store your sails. Definitely take them down, we’ve all seen furled headsails ragged by a winter storm, and take them off the boat and have them stored properly in a cool, dry, rodent-free place – our sail loft for example!

Even if you have your own space to store your sails; get them to the loft first. We see if every spring – ‘best intentions’ of getting your sails to us during the winter were packed away with them. Out of sight out of mind. You then have to join the long line to get your small issue fixed when you could be out enjoying your sailing.

We have a purpose-built storage area in our loft where we can keep your sails comfortable until you need them. We can also store your racing sails rolled – extending their life and keeping them nice and crisp.

Laundry & Re-Proofing

When we have your sails and covers for service we also consider whether they are due a wash. Every year we are asked to replace boom covers and sprayhood when really all that is needed is a good wash, reproofing, and a few stitches here and there.

Sails and covers are washed to remove and green mildew and general grime from the fabric. Covers are then re-waterproofed to give them an entirely new lease of life.

Now is the time!

Our schedule is filling up fast after a busy season on the water. Now is the time to get in contact and arrange your winter service. Let us ensure your sails are in top health and ready for your 2020 sailing season. Contact us at [email protected] or call our service manager Cleo on 021 483 1505.

McWilliam Sailing Bag Black Friday Specials!

A perfect Christmas gift for the sailor in your life - the McWilliam bag is the ideal bag to take on your boat, as it is rugged and water-resistant.

This Black Friday we’re offering 10% off everything in our McWilliams bag shop

There are a range of bag types available from holdalls of different sizes and colours, to Tote bags, T-shirts and hoodies too! They're the ideal stocking filler!

Go to the McWilliam Bag site here

UK Sailmakers Ireland: Top Tips for the Pit Role on a Cruiser-Racer

The pit or “strings” is a vital role aboard any boat; but not just mechanically, explains Barry Hayes of UK Sailmakers Ireland. A good pit person is involved in everything. Every sail manoeuvre, the start, on the rail, aiding communication and keeping the plan cohesive from front to back. Although often overlooked; it is actually one of the most important roles on the boat.

Many of us over our time sailing have done the pit and experience the pressure points of the role. Here are some tips to make your life easier and help the pit team, and boat, run like clockwork.

1. Main Halyard

Tie the main halyard back on to the clutch. We’ve all seen it. There is a high-pressure drop and in the rush, the wrong clutch is opened. This can easily happen if the halyard isn’t marked and it’s your first time on the boat. Tie it off good and tight so it’s never opened unless its meant to be.

Main halyard tied off

Main halyard tied off

2. Hatch Halyard Bag

Build a long halyard bags for the jib and spinnaker halyards. Two long pockets with wide openings. Each halyard goes into its own pocket so it never gets messed up / stood on / tangled or knotted. It also keeps the rope out of everyone’s way. I normally make them out of mesh.

Hatch Halyard bag

Hatch Halyard bag

3. Halyard Organiser

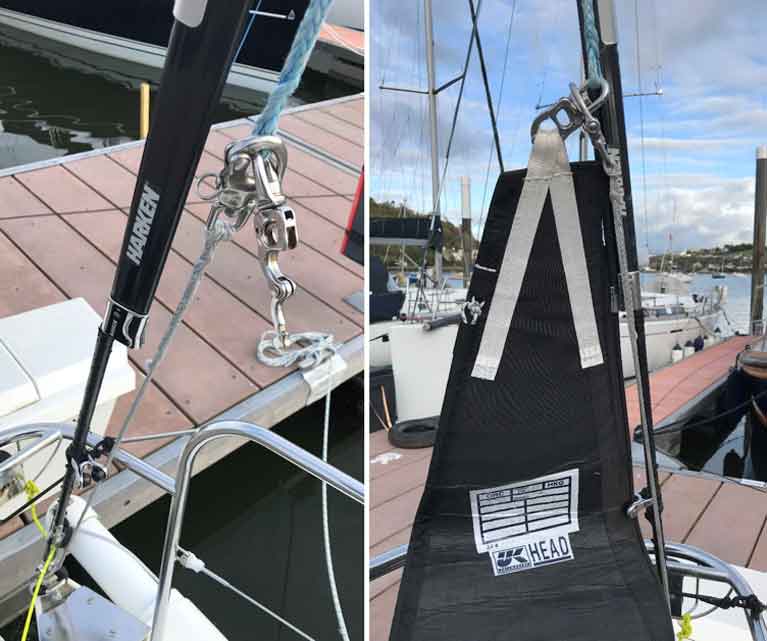

Add a Harken 56 mm crossover block to your pit setup. This allows you to take a halyard across to the opposite side winch and grind it up, under load, without any issues. This handy little tool saves time and space.

4. Hobbles

Use hobbles to your jib sheets. This frees up your genoa winches for bear away sets and drops. You can use the kite sheets on the genoa winch while having the genoa eased on the hobble for a hoist or drop. This gives you loads of time to load a sheet onto the winch. Simply put some spectra lashing through the genoa sheet about 1ft in front of the turning block. Spice a spectra strop about 2 feet longer than that point as per the photo. The jib can be eased out onto the hobble for the bear away, leaving the winch free for the kite sheet.

Jib sheet hobbles

Jib sheet hobbles

5. Fraculator

This is a simple tool to help the pit to be ready to hoist the jib at a moments notice. A fraculator allows you to keep the jib halyard under load, both pulling the rig forward and keeping the halyard tight to the forestay, removing any chance of the kite wrapping inside it on a gybe. Once you unclip the fraculator the jib is ready to hoist. A fraculator is normally a 1.2 / 1.4 m strop with a snap shackle, tied to the base of the forestay.

Fraculator

Fraculator

6. Spinnaker Sheets

If you use your top winches to trim the kite you can find yourself rushing to strip the winch and get the sheet loaded at the windward mark before the spinnaker hoist. Instead, loop the kite sheet loosely around the winch before loading up the genoa halyard for upwind sailing. That way it is ready for action when you drop the jib. The trimmer simply takes up the slack as you drop the genoa halyard off the winch.

7. Headsail Mark

Instead of having a mark on the jib halyard, put a mark on the headsail foil and a corresponding mark on the luff of the jib. So you can set the halyard to the correct tension no matter which headsail you have up. As the luff length change the so does the marks on your halyard so having a mark on the foil and the headsail maker the luff tension perfect every time.

Headsail Mark

Headsail Mark

8. Work With Your Mast Man. Not Against Him

Keep an eye on your mast man at all time. He is the key to your operations. Make sure your arm pulls are the same speed and length as his. You must keep the halyard flow going at a good even speed so the halyard doesn’t get jammed in the block. When hoisting you don’t need a winch to keep up with your mast man. The winch slows down the speed of the hoist. Just pull it from the back side of the clutch.

9. Code Zero

When dropping the code zero the bow man should be bringing it down to windward. Ease the halyard a little when dropping. But just 2 feet. So he can swing the sail over the forestay and get it under control. It makes the drop 100 times easier. Always leave the code zero halyard on the winch. as the clutch is not designed to take the load.

10. Halyard Drops

When dropping the kite you need to depower the sail quickly. The best way to do this, when the crew are ready, is to drop ¼ of the halyard. I normally have a blue mark on it so I know the point. Just open the clutch, fire the halyard and close it again when the mark comes to the clutch. I never use a winch to drop the halyard as it slows down the process.

11. Communicate from Start to Finish

Keep the commutation flow in the pit throughout the start sequence and beyond. Call the time for the crew and help with the calls on boats which may not be visible to the helm. Make sure to ping the start boat and pin end with your starting instruments. You’re the key to the team working well and the flow in the boat. The pit is the best link between the back of the boat thinking and the front of the boat reality. You have to play in both fields and keep the communication going. Listen to tactical calls from the back while feeding useful information back from the rail. Relay potential hoists, drops, sail changes etc to the bow team so they can prepare for any eventuality. Be clear and concise. Communicate with the team and do the best you can to help everyone do their jobs.

Optimize Your Tacking for Speed Around the Race Course

Tacking is likely the most common manoeuvre we execute on our boats. It is pretty hard to avoid in fact writes Graham Curran of UK Sailmakers Ireland.

Every second lost while tacking is multiplied 3, 4, 5, 6 times when beating, if not more! Having an effective tacking technique is crucial for speed around the race course.

Every boat is different, every crew is different, and every cockpit is different. Creating effective “lanes” within the cockpit when tacking is essential. It should be a finely choreographed dance. There is a lot going on in a usually crowded space. Putting a good system in place where everyone knows their lane will produce consistent, repeatable good tacks.

"Having an effective tacking technique is crucial for speed around the race course"

In general, I like to set up four lanes. The helm furthest aft in the driver’s enclosure. He has the most space as is usually out of the way so no problems there. If there is a cross over issue then the helm takes precedence. Wherever the helm needs to be before, during, and after the tack to ensure the boat moves smoothly is most important.

The mainsheet trimmer comes next, generally in the middle of the cockpit, usually always in the way. He has the traveller to deal with to best to give him some space.

Then come to the two trimmers. How you work together is important here as you are both on the rail before the tack. I assign trim one the task of managing the (one) winch handle, throwing off the loaded sheet, grinding in the new sheet, and finalising the trim of the sail. Trim two is assigned the task of pulling in the new sheet and tailing it while it is being grinded.

The process I use progresses like this:

- Helm calls the tack. Begins the “3 … 2 … 1 …” count.

- On 3 count; trim 1 comes off the rail and goes to leeward ready to release the loaded sheet. The windward winch is already loaded correctly (clockwise) with the new sheet and has the (one) winch handle in it orientated so it is not in the way when coming off the rail.

- On 2 count; trim 2 swings in off the rail and assumes the pulling position on the soon-to-be new sheet. He stays forward in the cockpit where possible.

- As the boat passed through the wind trim 1 throws off the loaded sheet and steps between the mainsheet man and trim 2 to the new leeward winch.

- As the boat passed through the tack trim 2 snaps the new sheet in, he then makes his way to the windward rail while tailing the jib sheet, he does not stand in the cockpit holding the rope. It is entirely possible to be fully hiked while tailing the new sheet.

- Trim 1 grinds the new sheet to 90% trim. He then grabs the sheet and shouts “my sheet” to trim 2. He takes the sheet and puts it in the winch self-tailor (if fitted) or puts an extra wrap on if needed. This short pause allows the helm some time to power the boat up of the partially under trimmed headsail after the tack.

- Trim 2 is now hiking his little heart out.

- Trim 1 brings the sail to max trim.

- Trim 1 ensures the sheet is securely cleated, takes the (one) winch handle and makes his way to windward.

- Trim 1 sits on the windward rail first, he then reaches back to load the windward winch with the jib sheet, pulls through any excess slack, and puts the (one) winch handle in, orientated correctly, ready for the next tack.

The above is the system that I like to implement as I believe it provides the most control to the trimmer and consistency to the helm. It is by no means the only system, as we will discuss below, but it works best in my experience.

VARIATIONS

There are many ways to tack a boat. Above I laid out my preferred method but I have sailed on several boats where it simply doesn’t work due to space/crew constraints.

A good example of this is the X302 or Beneteau First 31.7. Having two trimmers passing each other through the cockpit on these boats is just not possible. There is not enough space. As these are also boats primarily sailed with genoas, a mistake or delay can be very costly for boat speed and also the heart of the poor person who has to grind the sail in. The best solution I have seen for this is to have the mainsail trimmer throw off the loaded genoa sheet for the tack. This leaves trim 2 free to pass through the cockpit to tail, and trim 1 can be positioned over the new winch ready to grind as soon as the sail passes the mast, before it loads up.

Another similar example is a J109. Although the space is available on this particular boat, some crews prefer to have the pit person throw off the loaded winch and proceed straight to the rail. The two trimmers can then pull and trim in the jib as above.

It is worth experimenting to find a system that works best for your boat. Once you have found that system, stick to it, and make it second nature. That way when a new crewmember comes aboard, or as crew fluctuates throughout the season, you have a tried and tested procedure to teach, rather than having them figure it out themselves each time.

TIPS AND ADVICE

No matter what system you intend using there are little details that will make life easier. Stick to these and everything will run like clockwork.

Use one winch handle, two just doubles up jobs and causes confusion. If tacks are in short succession trim 2, instead of heading to the rail, or from on the rail if time allows, loads the new jib sheet and takes the winch handle from trim 1 if he is handed it. Trim 1 can also bring the winch handle across with him if under severe pressure.

Get over the winch. Whether you are releasing or grinding, the place to do it is standing directly over the winch. This is assuming your cockpit layout allows this. If you are above the winch you will be able to apply more force to the winch handle, making grinding much easier. Releasing the sheet is also much easier from this position as the sheet generally whips off the top of the drum once the sheet is held above it.

Deciding when to release the sail for it to cross the boat is the most important aspect of a good tack. Too early and the helm will need to use more rudder, slowing the boat. Too late and you’ll leave yourself with a lot of grinding to do. The trick here is practice and consistency. In medium sailing conditions, I tend to release once I see the front of the jib starting to luff/bubble. This indicates that the helm is just about to pass the boat through the wind. The sail is them pulled in on the new side as the boat is passing through head to wind, where there is little or no load on the sheet.

If the wind is lighter I will hold the sheet longer, allow the sail to ‘back’ to assist the bow through the wind. This makes pulling in on the new side a little harder but this is ideal as we do not want to be fully trimmed in in this lighter wind strength, we want to be slightly eased to build speed exiting the tack.

If the wind is heavy I will release slightly sooner. This will allow the boat to deload a little and flatten smoothly through the tack. It also makes it easier to pull in on the new side, which is going to be hard regardless due to the wind strength, and will mean a little less grinding for the primary trimmer.

Discussing and talking to the helm when making this decision is very important. If you’re going to back the jib then tell the helm, and your second trimmer, so they will expect it. If you’re going to do it then do it for every tack. Not one in every five. The helm can then dial in exactly how much rudder is needed to turn the boat with the aid of the jib. If you decide to stop backing the jib suddenly the helm will find himself mid tack and having to make a large correction to compensate to the change in jib trim.

Self-tailing arms and foot holds. The self-tailing arms on most winches can be very obstructive when trying to release a loaded sheet. On most winches it is possible to orientate the arms in different directions. I find having them facing at around 7 o’clock keeps them out of the way for the most part. Quicker release makes pulling in the new loaded sheet that bit easier.

Another big consideration is having a solid foothold on the rail for the trimmer. If you want to get your trimming over the winch then you better make sure they are comfortable standing there. Some yachts have a well-placed stanchion at this point, others have pre-installed wooden wedges. If you don’t have anything it would be well worth taking a look as this small change could transform your tacking.

SO WHAT IS THE POINT?

Ultimately the point of all this is to minimise loss. Tacking is a costly manoeuvre in most boats, but the loss is unavoidable. The more you can reduce the loss, the more options you have, the greater the chance of you winning the race. We do this by maintaining speed, done by using less rudder (jib release timing critical!). By ensuring weight is in the right place as quick as possible (trim 2 getting to the rail asap). And by making the entire manoeuvre a repeatable learnable process. If you do this right and practice it; you will find yourself occasionally giving out about a bad tack, rather than being astonished by a good one!

Winter Sail Service – Is it For Me?

It is approaching the time of year where we make the most of what is left and prepare for the off-season pack up writes Graham Curran of UK Sailmakers Ireland. The Autumn/Winter period is the best time for buying new sails, and for getting your sails serviced. Whether it’s your car, your own health, or your sails, it is no secret that an annual check-up and service is the best way to protect your investment and avoid trouble down the line.

Our sail loft in Crosshaven, Co Cork, has been a sail service centre for over forty years. Thousands of sails have been on our floor and it’s not often we see something we haven’t encountered before. We can spot issues before they emerge as serious problems. This will not only save you money – but also time. No one wants their sails on our floor when they should be on your boat out sailing!

"it is no secret that an annual check-up and service is the best way to protect your investment"

Depending on the type of sailing you are doing an ‘annual service’ can consist of many different things. Some of you may even ask “do I really need to?” The short answer is –yes you do – let me explain why.

Club Racer

If you’re a club racer then you’re the most likely to be asking the “do I really need to?” question. In fact, your sails will likely benefit more than anyone else from a good annual service.

When we receive your sails in our loft we give them a full check over. We check all luff tapes for tears, check common wear spots such as where it interacts with spreaders and stanchions, check for missing tell tails, and identify if there are any unknown causes for the problem which is presenting itself on the floor.

For example; we see many luff tape repairs throughout the season and during winter service. Luff tapes don’t just tear. If they tear then there is a reason why. Sometimes it can be a simple mistake of sheeting on too early or skipping the feeder – but often there is a problem which can be solved on the boat. We discuss potential issues with our customers and present solutions to avoid damage occurring in the future.

While we have your sails we can re-measure them for IRC. This can lead to a nice reduction in your IRC handicap upon your revalidation for the 2020 season.

Our expert staff pick up details which the untrained eye would overlook. Leverage this experience to protect your investment and maximize your time on the water come next spring.

Coastal Cruiser

If cruising or day sailing is your thing then you likely have a UV strip on your headsail and plenty of covers, sprayhoods, dodgers etc.

One of the worst things you can do for your sails is to leave them on your boat for a prolonged period of time – even during the sailing season. If you are not going to be using your boat for a month or more then take down the sails and store them aboard. If you only wear your good flamingo shirt to weddings, and you don’t have one for two months, you aren’t going to leave it hanging on the line!

Exposure to the sun degrades your sails and covers – this is simply a fact of life. The UV light breaks down the fabric and especially the stitching. During an annual check-up, we inspect your entire UV cover and its stitching. A quick run through a sewing machine now is much more cost-effective than having to replace an entire torn UV strip after an Irish winter storm. The same goes for your covers. Deliver them all to us together for a full assessment.

Storage

When you are packing your boat up for the season you should also be thinking about where you are going to store your sails. Definitely take them down, we’ve all seen furled headsails ragged by a winter storm, and take them off the boat and have them stored properly in a cool, dry, rodent-free place – our sail loft for example!

Even if you have your own space to store your sails; get them to the loft first. We see if every spring – ‘best intentions’ of getting your sails to us during the winter were packed away with them. Out of sight out of mind. You then have to join the long line to get your small issue fixed when you could be out enjoying your sailing.

We have a purpose-built storage area in our loft where we can keep your sails comfortable until you need them. We can also store your racing sails rolled – extending their life and keeping them nice and crisp.

Laundry & Re-Proofing

When we have your sails and covers for service we also consider whether they are due a wash. Every year we are asked to replace boom covers and sprayhood when really all that is needed is a good wash, reproofing, and a few stitches here and there.

Sails and covers are washed to remove and green mildew and general grime from the fabric. Covers are then re-waterproofed to give them an entirely new lease of life.

Now is the time!

Our schedule is filling up fast after a busy season on the water. Now is the time to get in contact and arrange your winter service. Let us ensure your sails are in top health and ready for your 2020 sailing season. Contact us at [email protected] or call our service manager Cleo on 021 483 1505.

Offshore Sailing Top Tips from Yannick Lemonnier of UK Sailmakers Ireland

Although the offshore sailing season is drawing to an end; it is never too early to look to your 2020 sailing season. Offshore racing, both crewed and shorthanded, is one of the biggest growth areas of sailing domestically and internationally.

UK Sailmaker's Yannick Lemonnier is one of the most experienced offshore racers in the country. With over 10 years of experience and more than 80,000 miles under his belt, mostly solo and double-handed, he is full of offshore sailing knowledge. Here gives us some top tips to bring into your 2020 offshore sailing season.

The Mainsail

The main is the one sail that we always have up, no matter the point of sail. Trimming and managing it is crucial to success – so how can you make life a bit easier?

A reefed mainsail

A reefed mainsail

- Stitch all your battens. This is as simple as using a hand sewing needle to put a quick stitch at the extremity of each batten pocket. This fully secures your battens no matter what weather you encounter. The consequences of losing battens can be dramatic for the integrity of the sail and its performance.

- Reefing. Tie the bottom part of your mainsail with small diameter bungee and plastic clips instead of solid rope. Releasing your reef with one tie remaining can seriously damage your sail – and can easily happen when tired or on a dark night.

- Glow-in-the-dark draft stripes. These make trimming your sails at night so easy. Each stripe should be marked at the 50% chord length to give a good shape reference. These stripes can be retrofitted to older sails (depending on their age).

- Reef assistant. This is a great option for regular offshore racers. Basically it is an additional pennant set just above your reefing eye at the luff end of your mainsail. It gives you a solid anchor to either pull your reef towards its hook or release pressure to unhook the reef in strong winds.

- Tie up the sail, not the boom! This is one we see a lot. When lashing up your reefed sail to not tie it around the boom. Instead, lash it around itself. You should have a tie going from the leeward side, around the loose sail between itself and the boom, and tied securely on the windward side with an easy to release knot.

Glow in the dark sails

Glow in the dark sails

A reefed mainsail tied

A reefed mainsail tied

Headsails

When sailing upwind or tight reaching, depending on your inventory, you will be using your headsails – quite likely multiple headsails. Keeping on top of them and practising crew manoeuvres with them is critical to a successful offshore race.

- Stitch all your battens. This is the same as with your mainsail – but even more so as your headsails are more exposed to flapping as they are hoisted and dropped. Securing the battens is essential. This is a really quick and basic job which can prevent a lot of trouble down the line.

- Peels and tack peels. This manoeuvre is a must – and it is not complicated with proper training and the correct setup. Having a second attachment either side of the tack attachment point is recommended. And make sure to keep a close eye on your halyard to ensure no wraps occur. I would recommend to always drop the sail on the inside as dropping outside is risky and can lead to you losing your sail!

- Glow-in-the-dark draft stripes. As with the mainsail, these make setting halyard tension, car positions, sheet tension etc much more efficient at night. Glow tell tails on the luff make steering and trimming a doddle on those dark nights.

- Spare sheet and block. This is to clip onto the outside rail, or purpose installed padeye, to outhaul the headsail on a reach. This is essential. Every time your clew moves up and down you are losing power. A well-positioned outboard lead padeye and the hardware to go with it makes a huge difference to off the breeze speed.

- Know your inventory. Knowing your sails is critical regarding wind range and angles. Where is your limit between J2 and J3? Between an outhauled genoa and code zero? The only answer is practice and recording. Experiment with different setups and take note of what works, and more importantly, what doesn’t!

Outboard lead

Outboard lead

Spinnakers

We all love sailing downwind when offshore. It can be fast and fun. It can certainly be a lot more comfortable than beating into a gale! But it brings its own challenges.

Spinnaker stops on sail tack

Spinnaker stops on sail tack

- Choose your colour carefully. White spinnakers are difficult to trim at night. They are like a ghost. I would recommend a dark colour to get more contrast – I also find white harder on your eyes in bright sunshine.

- Velcro for control. Heavy spinnakers should be equipped with Velcro banding to keep them deflated while hoisting. They allow you to hoist the sail and stabilize the boat, then pop the sail out when everything is ready.

- Repair early. Gets lots of 100mm insignia tape (stick-back dacron) to fix small tears that can become a bigger problem. This tape can also fix other sails along with a bottle of acetone (nail varnish remover) to remove salt and dry the sail surface.

- Inspect for chafe. Don’t worry, we’re talking about your halyards! If on a long spinnaker run chafe can become a real issue. Covers can wear on sheaves or deflectors overnight. Ease the halyard a foot and check with the binoculars for visible signs of damage. If you can see it with binoculars it will be a bigger problem sooner rather than later.

- Peeling practice. Peeling spinnakers is actually easier than peeling headsails. The most crucial element is good halyard management. Have a spare peeling sheet, with snap shackle, ready and accessible. Think and talk the manoeuvre through – and, as always, practice!

Storm Sails

Whether we like to admit it or not, there is a tendency to see storm sails as a box-ticking exercise. Not many sailors have a clue how to rig them, never mind use them properly!

Storm sails

Storm sails

- Firstly they should be stored in a separate dry bag. Piston hanks tend to corrode in an offshore environment unless used regularly – they should be replaced with soft shackles.

- The storm jib should have a tack strop of a set length. This should position the sail at a height that lines the clew up nicely with your jib car position.

- The trysail should ideally be on a separate track. It should be rigged with spinnaker sheets lead inside the guard rails – as we discovered after training in just under 50 knots!

Summary

A huge part of offshore racing is managing your energy. By making the boat as easy to sail as possible, and removing any potential issues before they occur, you can put 100% of your energy into making the boat go fast. Plan, practice, and enjoy your offshore adventures

From Concept to Reality – XP44 'WOW'

In early 2019 the news broke that there was a new “WOW” on the way to Ireland from Lisbon. George Sisk had added a new XP44 to his line of successful racing yachts named “WOW”. Barry Hayes reports on the role of UK Sailmakers Ireland.

Following a competitive bid process; the UK Sailmakers Ireland team was chosen as their sailmaker for the project. We hit the ground running and, having a strong working relationship from the previous WOW campaign, we were able to work closely with George and his team to get as much info about the new boat as possible before her arrival.

Research and Requirements

The first phase of any project is to research the boat you are working with, its behaviour and performance characteristics, and gather the requirements of the owner. This gives us a clear path toward success.

Performance Research

The XP44 is a regular competitor in events throughout Europe, both inshore and offshore. We gathered key IRC data and past race results to give us a picture of where the boat performed best, and what her disadvantages were. We found that reaching, sail handling, and her IRC handicap were key issues which needed to be addressed.

With our polar performance data from other XP44s in hand; we gathered further data from other UK Sailmakers lofts in our network who have raced and made sails for the XP44, and what their overall impression of the boat was. Digesting this experience, and cross-referencing it with our performance analysis data, allowed us to refine our design and optimisation approach for the WOW project.

XP44 Maestro with sails by UK Sailmakers Ukraine

XP44 Maestro with sails by UK Sailmakers Ukraine

Requirements

With a good understanding of the performance characteristics of the new boat, we could focus on compiling the key requirements for the campaign. A major part of this is the events the boat would compete in, who she would be racing, and the prevailing conditions she would be racing in.

These requirements then steer the sail wardrobe development and design as well as the IRC optimisation process.

The main focus for the WOW campaign for 2019 was coastal racing, major offshores, and local DBSC racing. This put usability and straight-line speed at the top of the priority list. It also meant that a significant amount of the off-the-wind sailing the boat would be doing would be tight or broad-reaching as opposed to the deep downwind sailing you would get if the boat was solely focused on inshore windward-leeward course racing.

From our performance analysis, we knew that reaching was one of the boats main weaknesses. This is due to the balance of the boat. When reaching the powerful mainsail needs to be offset by a strong sail force forward of the mast. If this is not done then the boat has a tendency to spin out to windward in gusts rather than accelerating – causing the helm to constantly fight the boat with the rudder. We will talk about our solution to this issue in our sail specification and design later in the article.

We concluded our requirements gather phase with the following initial requirements:

- Optimize performance for light/medium conditions

- Balance helm off the wind

- Maximize usability and simplicity of the sail wardrobe

- Ensure power is controlled in heavy airs downwind

Bowsprit

Early in our discussions, it was decided to fit a longer bowsprit to the XP44. This additional length would give us a better aspect ratio for the spinnaker designs (STL:SPL). It also gave us more option in the forward sailplan of the boat for keeping the helm in balance, discussed further below.

IRC Optimisation

Graham Curran focused on the IRC rating optimisation process. We knew that the boat performed well in the 8-10 knots wind range based on the polars and weight/wetted surface numbers for the boat. Our goal was to maximize this performance range, achieving the best power to weight ratio possible, while optimising the IRC rating for the required sail area.

A major part of this optimisation was the HSA (headsail area). We shortened the LL of the headsails (luff length) as much as possible while maintaining area by pushing out the LP and girths to the maximum we could fit in the foretriangle. This gives maximum benefit of sail area vs IRC penalty while also maximizing the inhauling effect of the jib leech.

This takes a lot of work and several trial certificates to perfect but we had already done a lot of work on the subject with our J109 development the previous winter. With accurate measurements, 3D modelling, and IRC certificates; we knew exactly what we were looking to achieve performance wise vs the final IRC rating.

Sail Wardrobe and Design

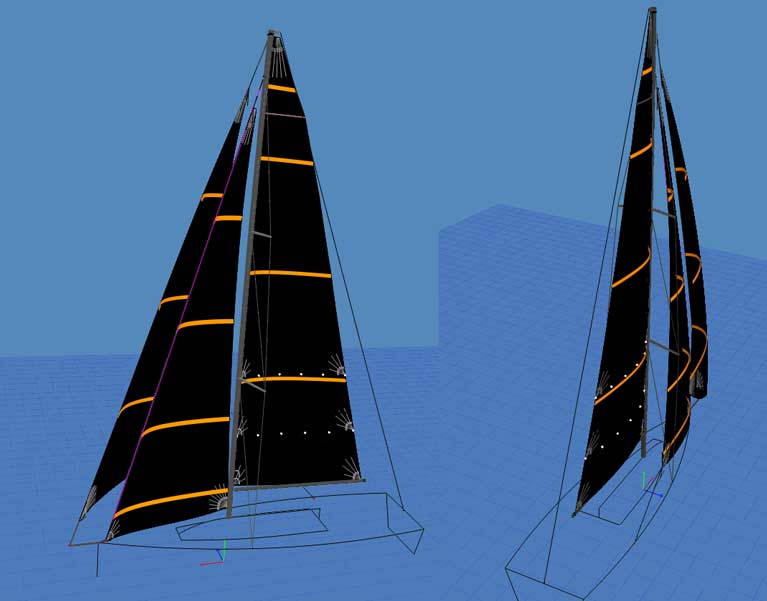

In conjunction with the IRC optimisation, Barry Hayes began specifying and designing the sail plan. The first phase of this is accurately modelling the yacht and her sail plan in our 3D design software. We then refine this model throughout the design and optimisation process.

XP44 modelled in real-time 3D. This is the base model for the design phase

XP44 modelled in real-time 3D. This is the base model for the design phase

Reaching Performance

Our performance data clearly showed that there was an issue with the reaching performance of the boat. We had an indication that this was due to the balance of the boat so our first step was to assess the lead of the boat.

MH0 (masthead code zero)

MH0 (masthead code zero)

‘Lead’ is the distance between the centre of effort of the sail plan, usually the Working Sail Area which is the main and fore triangle (CE); and the Centre of Lateral Plane of the hull/foils, (CLP). Both the CE and CLP are approximate positions for the centres of pressure for the sail area and the hull underbody and only really used by yacht designers at the design stages to ensure that the keel and rig positions are well balanced.

This assessment reinforced our understanding of the problem; and what our solution would be.

It was clear that we needed to have a MH0 (masthead code zero) in the inventory. This large code zero helps by pushing the bow down, counteracting the mainsail, and keeping the boat in balance on a reach. The MH0 needs to be a little smaller than maximum to ease sail handling and for use while tight reaching/near upwind work in light airs.

Throughout this design process it became clear there was another performance window to be exploited.

The MH0 is simply too much sail area for tight reaching between 50-70° apparent, depending on the wind speed. This would put the boat back on a full mainsail and headsail, with imbalance remerging as a result. The solution to this issue, and a clear performance gain, was a Flying Jib.

This sail is the same area as the maximum IRC headsail area because, as the name suggests, it measures as a headsail rather than a spinnaker like the code zero. The flying jib is set of the end of WOW’s extended bowsprit, giving greater separation from the forestay and allowing a ‘double-headed’ headsail setup with the J3 set on the forestay foil, and the flying jib outside it. It is also a furling sail – functioning like a furling code zero.

We virtually analysed the flying jib at the 50-70° angles and found a speed increase of approximately 1.2 knots while also keeping the boat balanced.

As the boat comes off the wind she will swap back to the larger MH0. Filling this gap with the flying jib allowed the MH0 to be increased in size, making it more effective downwind. Combining the two sails in the inventory made each sail better than either could be on their own. WOW now had a full effective reaching range from 50° AWA with her flying jib to 130° AWA with the MH0.

Upwind Package

Given the target HSA from our IRC optimisation; Barry moved on to the design of the upwind sail inventory. The designs were based on the polar performance data from the current sail plan which were then refined to allow additional inhauling with a twisted headsail design – allowing greater pointing without sacrificing speed – while maintaining our target IRC rating.

Upwind sailing

Upwind sailing

Handling of the mainsail was a major point of discussion within the team – the mainsail would have to function well both inshore and offshore with usability being paramount. Reef heights, luff tape or slides, full battens or short – all these decisions were influenced by this discussion with the team. We worked off the fact that other XP44s use a luff tape on their mainsail – this proved to be a difficult setup with the external mast track. We spoke with our UK Sailmakers partners who advised us on ideal luff setup and effective reef heights from their experience.

This additional information simplified the decision for the team. The mainsail was specified with two reefs, Antal luff sliders, and short leech battens.

To further optimise the IRC rating we put a small fathead on the mainsail and reduced her P measurement – resulting in a favourable aspect ratio.

Downwind Spinnaker Package

The main concern for the team was boat handling downwind in heavy airs. The XP44 has a bit of a reputation for being a handful when the breeze is up as she doesn’t plane. Solving this issue and getting the best performance from the SPA (spinnaker area) was the last critical step in this design phase.

From running trial certs we found that 190m2 produced the best power to weight ratio with a favourable rating. We worked from this number to determine the size of her working spinnakers.

The A1.5 is a sail made for light air performance. It is designed to work at tight VMG angles in light airs and then rotated once the tack is eased in building pressure. This would be the workhorse of the boat on Dublin Bay.

Downwind sailing

Downwind sailing

As the boat would be rated with three spinnakers the last slot was reserved for a heavy air spinnaker. We design a hybrid A3/A4 sail which we have worked with extensively in the past. It is designed to be an A3 (medium air reacher) when flown from the masthead halyard but doubles as an A4 (heavy runner) when flown from the fractional halyard. The smaller area required for an A3 tied in well with our power management requirement for the heavier air A4. The logic for using the fractional halyard for the A4 is purely for boat handling. The boat does not need the additional power in heavy airs and bringing the hoist down makes the boat more stable and easier to handle.

Sail Testing and Performance Analysis

Once WOW arrived in Dun Laoghaire she was immediately weighed and measured for her new IRC certificate – including the new extended bowsprit.

At this stage, the sails were in production and were soon delivered to the boat to be fitted and tested with Barry and Graham.

The code zero was to fly on a padeye on the bow of the boat, just in front of the forestay, while the flying jib is flown from the end of the bowsprit. Load testing these points, the halyards, and the hardware that holds them is extremely important before ever leaving the dock. It is the safest way to load the boat and give the crew the confidence to take the gear offshore without any doubts in their mind. After several full load tests and adjustments of the bobstay, it was time to go sailing.

Adjusting bobstay tension is when teamwork really shines

Adjusting bobstay tension is when teamwork really shines

One the water we set up all the sails and optimised deck layouts, the run of furling lines, sheets, halyards etc. We then assessed the boats upwind performance by fully loading the Uni-Titanium upwind sails and confirming the rig’s bend characteristics.

Team Approach to Development and Results

We worked closely with the WOW team to bring their concept into reality – it was now time for the new XP44 to go racing. Straight away she was top of the DBSC results pages winning her first Saturday race on the bay. She finishes up her 2019 DBSC season winning the overall Thursday league and, at the time of writing, leading the Overall Saturday series.

Her most notable performance of 2019 was at Kinsale’s Sovereigns cup where she went bow to bow, wave for wave with her bigger sister, the XP50 “Freya”. It was amazing sightseeing these yachts battle off the coast of Cork for the week – with WOW triumphing with three wins from three races.

“As soon as Barry and Graham of UK Sailmakers heard about George’s new Xp 44 WOW coming to the bay, they got to work analysing the best sail package for the boat based on what we intended to do with her. Once the new sails arrived, they were available to set them up and work with us to achieve the best outcome from them. Since then, nothing has been too much for them. The UK team has been available at a moment’s notice to provide solutions to all sorts of problems – from damaged sails to broken parts and even the design and supply of a cockpit tent, as well as the set up and trim of the new sails. In my opinion, the collaboration between WOW and UK Sailmakers has been instrumental in the success of our first season with the Xp 44 WOW. We are looking forward to continuing – and growing – our relationship with the UK Sailmakers Ireland team in 2020 and into the future.” – Gavin Stillman, Boat Captain

UK Sailmakers Ireland: Top Tips for Leeward Mark Perfection

We all know sailing fast in a straight line is very important. That is where, as sailmakers, our products shine and our technical background can be leveraged for your benefit writes Graham Curran. But races are won and lost at the corners. You can be the fastest boat on the water but if your critical manoeuvres are not dialled in then one bad hoist or drop could have your advantage erased immediately.

Let’s take a look at look at leeward mark rounding techniques and present some top tips for perfecting your manoeuvres. With that said; there is a lot going on at the leeward mark with a lot of elements in play, including conditions, spinnaker setup, boat size, course layouts etc, so this list is no means exhaustive, but if you can work on these general points then you will be many steps closer to that elusive perfect leeward mark rounding.

A leeward mark at July's Volvo Dun Laoghaire Regatta Photo: Afloat

A leeward mark at July's Volvo Dun Laoghaire Regatta Photo: Afloat

We are going to break our tips into light air tips and heavy air tips. As we will see, the wind speed plays a major role in how you should approach your drops.

Light Airs

- Keep your spinnaker flying as long as possible. In light airs, it is easy to be over-cautious with your spinnaker drops – dropping the spinnaker early and slowing boat speed significantly. We need to keep the spinnaker driving the boat for as long as possible to get us to the leeward mark at maximum speed. As the wind is light we will have plenty of time to get the sail down as we turn around the mark.

- Partially hoist your jib but not so much that it affects the spinnaker. Getting the jib up is good, you’re certainly going to need it, but timing is everything. When the jib is in the air it immediately begins effecting the airflow onto and across the spinnaker with the potential to collapse it early – we’ve all been there and it isn’t fast. Half hoist the jib so the first couple of battens are clear of the guard rails – this keeps the spinnaker clear while also ensuring there are no issues with the jib hoist itself. Once the drop (and the mark) are imminent – hoist the jib fully. Make sure the jib sheet is loose. This will help keep the kite going to the very last second. When rounding trim the jib constantly as the boat turns – do not ram it in early to save yourself some grinding on the other side!

- Manage your crew weight. I cannot stress this point enough – especially in light airs. Once the spinnaker is down and not in the water – sit down. Get to leeward if the conditions require it and stop moving. The best drops can be ruined by a bouncy crew on the deck. At this point, it is critical for the boat to build speed and exit the mark as fast as possible. Generally, at this point we are trying to escape the fleet or get to the favoured side – boat speed is of utmost importance. An over-eager bow crew preparing for a windward mark that is 40 minutes away is simply not helpful. Sit down, settle, let the boat accelerate, and then pick your time to do your jobs.

- Keep your trimmer focused. There is a lot going on at the leeward mark. Boats approaching, likely plenty of shouting, sails going up and down. It is critical for your spinnaker trimmer to stay 100% focused at this point. As the jib goes up the spinnaker behaviour will change and trim will need to be adjusted to keep it drawing. Active trimming here is worth its weight in gold. As the old saying goes – “if in doubt, leave it out”.

- Plan ahead to optimize your crew work. Ideally you want to drop the spinnaker on the side which it will hoisted at the next mark. This is not always possible but it is what we should be aiming for. This results in less work for your bow team and pit crew, which means less running of gear, more weight effectively placed for longer. Know your course and know what drop option will suit you best – then try to make it happen.

A Spinnaker drop at a leeward mark in a Beneteau 211 Photo: Afloat

A Spinnaker drop at a leeward mark in a Beneteau 211 Photo: Afloat

Heavy Airs

- 1. Manage the spinnaker halyard. It should go without saying that the spinnaker halyard should be flaked and ready to run. The pit crew, when the drop is called, should smoke ¼ of the spinnaker halyard to instantly depower the sail and allow the bow crew to get a good handful of the sail into the boat. Once this is done the halyard should then be eased gradually to ensure the sail does not end up in the water. The faster this first portion of the halyard is blown the better – you want to shock the spinnaker into submission!

- Get the pole away early. In moderate/heavy airs there is plenty of pressure in the spinnaker to keep it set. The pole can be cleared early to make the drop much cleaner and give you more options for manoeuvring during and after the drop. If flying a symmetric spinnaker use a crew member to “human guy” the spinnaker to help the trimmer maintain control. If flying an asymmetric spinnaker “clearing the pole” is as simple as un-cleating the pole outhaul rope before the drop so that when the spinnaker unloads and is being recovered the pole is automatically pulled in – just keep an eye on your tackline so it doesn’t go under the bow!

- Get hiking! Similar to light airs, crew weight management is crucial. Get the weight on the rail as soon as possible. If the kite isn’t at risk of going in the water and the boat is clear to tack then your weight should be hiking – not tidying. There is an entire windward leg to prepare for the next hoist or coil your sheets. Hike first, housekeep later.

- Drop early and gain. Much the opposite of the above – push to your limits, not beyond them. An early drop doesn’t hurt boat speed significantly in a heavy air situation – having the spinnaker still in the air as your turn upwind however very much does. Get the spinnaker down early and safely and get the crew to where they need to be as you turn the corner.

- Avoid a leeward drop. In heavy airs, leeward drops are just asking for trouble. Sometimes it is unavoidable but if at all possible use any other option.

Put in the time

“Time on the water is king” – there is no denying this. The more you and your crew sails together the better your manoeuvres will be. And its time well worth spending. Put in the practice before racing begins and give yourselves time to learn.

On top of this – know your limits. It is tough, when in the heat of battle, to take a step back and assess the situation. It is crucial to know what you are capable of as a crew. This will allow you to push your drops to the limit, but not beyond them, and by doing so you will gradually improve as the manoeuvre becomes smoother.

Get out on the water and make the most of the upcoming Autumn Series! See you on the water!

UK Sailmakers Ireland: Five Top Tips for Buying Sails

Olympic sailor Mark Mansfield who is an agent for UK Sailmakers Ireland offers his five top tips for those looking at buying new sails this year.

1. Correct Size Sails

Make sure the new sails are the correct size. IRC rule changes are happening all the time and good advantages can be had from optimising the sail sizing, sometimes by just a small amount. Make sure you get advice from your sailmakers about what is best. We had one Class One boat this year that ended up with the same size sails as before but dropped two points by changing the shape of their sails a small amount.

Black Velvet Beneteau 34.7 with her Uni Titanium Main and Headsail. Black Velvet recently converted to non-overlapping headsails

Black Velvet Beneteau 34.7 with her Uni Titanium Main and Headsail. Black Velvet recently converted to non-overlapping headsails

2. Seasonal Discounts

Make sure you take advantage of any discounts that might be available. Autumn is traditionally a quiet time for production facilities and so discounts are offered for orders at that time. At UK Sailmakers, we have just introduced a new discount arrangement. More details here

3. Sailmaker's Knowledge

Make the best use of your Sailmakers. People working with sailmakers have a wealth of knowledge about what makes boats go fast. Whether it is helping you with your rating optimisation, helping you tune your rig or other areas, make use of them. Sometimes this can be added as an included extra in a sails purchase deal.

4. Loft Facilities

Ensure the sailmakers you are thinking of has a proper loft to be able to service and adjust your sails. Ordering from a sailmaker with no proper loft facilities means adjustments or repairs are extremely difficult to organise. We recently had a customer who twisted his Code 0 cable and was unable to untwist it himself. It went down to our loft in Crosshaven where the 17-metre sail was hung up, untangled and refitted. This would be very difficult to achieve without proper facilities.

5. Sails to Suit Requirements

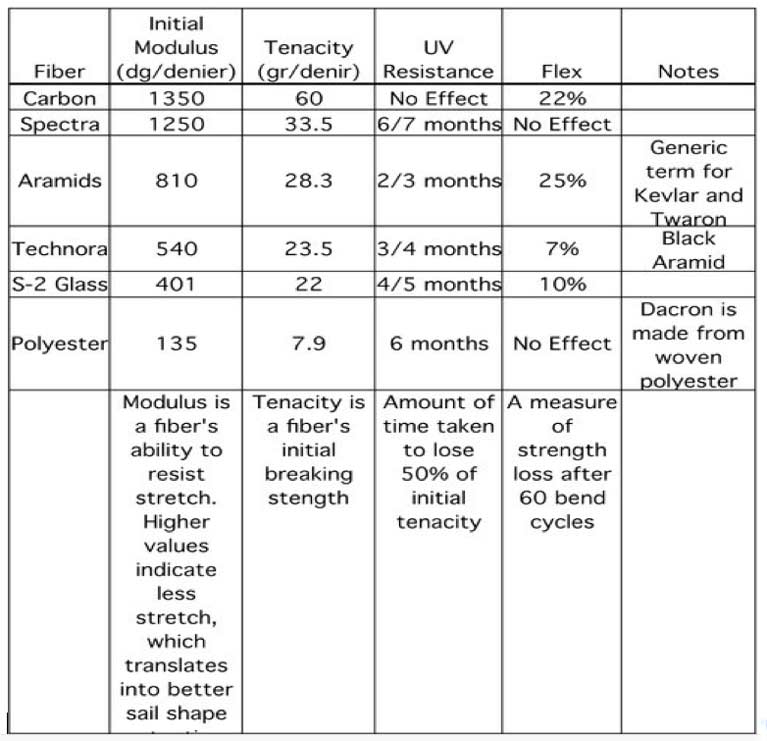

Make sure you are being quoted the material in the sails that suit your requirements and not some lower-tech and cheaper material that looks fancy but actually will stretch very quickly and not last long. For racing boats over 30 foot or even a bit smaller, the go-to material for quite a few years for low stretch is Carbon. The problem with not having Carbon in high load sails is if you exceed their normal wind range, they will eventually stretch, and once that has happened, you end up with turned in leeches and baggy sails. They will not last competitively for the same number of years as Carbon-reinforced sails.

George Sisk's new X Yachts XP 44 Wow on way to winning the 2019 Sovereign's Cup with her Carbon Uni Titanium Main and Headsail Photo: Bob Bateman

George Sisk's new X Yachts XP 44 Wow on way to winning the 2019 Sovereign's Cup with her Carbon Uni Titanium Main and Headsail Photo: Bob Bateman

So, Why Carbon?

A quick history lesson on sail materials.

Up to the ’70s, nearly all sails were made from Dacron (Polyester) and were 'crosscut'. Fairly cheap, stretchy material, but lasted a long time.

In the late ’70s, new materials such as Mylar emerged with much less stretch and were used for quite a few years.

In the early ’80s, Kevlar became the go-to material. Originally used for bulletproof vests, it had good stretch resistance but was more expensive. The first Kevlar sail I ever sailed with was on Moonduster in 1981, her first year, when she did the Admiral's cup. Kevlar sails in those days were still crosscut.

In about 1982, tri-radial sails, using a combination of Mylar in the low stretch areas and Kevlar in the high stretch areas(such as the leech) changed the way sails were made forever. Kevlar, however, has low UV protection and stretches after a lot of flogging and wear.

In the early 2000s, Carbon was introduced to sails and this was another game-changer. Much less resistant to UV damage and significantly less stretch. It has become the option of choice for the racing community. It is more expensive, however, which is why some sailmakers when in a competitive situation, sell sails without Carbon.

At UK Sailmakers, our Race sails (X drive Carbon, Titanium and Uni Titanium) are all Carbon-reinforced sails. The latter two options are moulded sails.

The graph below shows the strength differences

If you are buying new sails, here is what you should be looking at:

- Fully Cruising - Dacron is fine

- Cruising and occasional races on Echo - Dacron is still fine

- Racing mainly and occasional cruising - Carbon-reinforced sails such as UK Sailmakers 'X drive Carbon'

- Racing mainly, club level - Carbon-reinforced sails such as 'X drive Carbon'

UK Sailmakers Ireland: Winter is Coming …

Returning from (attempted) racing last night on Dublin Bay, one of the crew reminded us all that there are only two Thursday evening races left in the DBSC season writes Graham Curran of UK Sailmakers Ireland. Summer 2019 has gone by quick – although there is still plenty of sailing to be done throughout the country.

As the summer season draws to a close it is time consider what can be done to improve your sailing for the 2020 season. Take advantage of the autumn sailing season to assess your sail wardrobe needs.

Bolster your sail wardrobe for maximum performance

(From left) “Outrajeous” Sovereigns Cup Champion – “Rockabill VI” Dun Laoghaire to Dingle Champion – “Mermaid IV” Dun Laoghaire Week Coastal Champion

(From left) “Outrajeous” Sovereigns Cup Champion – “Rockabill VI” Dun Laoghaire to Dingle Champion – “Mermaid IV” Dun Laoghaire Week Coastal Champion

New sails make a big difference to your boat’s performance both on and off the race track – especially when coupled with the expertise of a professional who can show you how to use them for maximum effect.

The UK Sailmakers Ireland team of Barry Hayes, Mark Mansfield, Graham Curran, Yannick Lemmonier and Andrew Steenson have vast experience to share with our customers.

And there is no better time to buy than during the autumn period with up to 15% off retail pricing. Make the most of your autumn sailing and get one of our team out to assess your wardrobe and advise on areas for improvement.

Contact any of our expert team for advice, guidance, and a quote today. See contact details below