Displaying items by tag: UK Sailmakers Ireland

Four-time Olympic Helmsman, Sailing Coach and Agent/Consultant for UK Sailmakers Ireland, Mark Mansfield explains how the Helm and Trimmers on larger keelboats and cruisers should be in continual communication to go fast on the race course

Following on from the successful series on Top tips articles dealing with upwind and downwind sailing over the last few months, I am now going to go through how a Helmsman or woman and their trimmers should work together for the best results.

Most helms will likely have at some point raced smaller keelboats or dinghies, where the helm not only steers, but also controls the Mainsheet or the Traveller, or both. This allows the feel and weight on the tiller to be handled by the helm and allows the helm to react quickly and proportionately by adjusting the traveller, mainsheet, or even backstay. On bigger boats, the loads are more substantial, and often a specific mainsheet person controls all of these.

Downwind how deep you steer is also quite tricky to work out and again there is someone else, usually the Spinnaker trimmer very much involved. So for this article, I will break down my thoughts into

- Upwind—Helm working with the mainsheet trimmer

- Downwind—Helm working with the spinnaker trimmer

Author Mark Mansfield is working with John Maybury on J109 Joker II on her way to winning her third straight ICRA Nationals in 2017. Joker 2 will be going for four in a row in 2019 as there were no ICRA nationals in 2018 Photo: Bob Bateman

Author Mark Mansfield is working with John Maybury on J109 Joker II on her way to winning her third straight ICRA Nationals in 2017. Joker 2 will be going for four in a row in 2019 as there were no ICRA nationals in 2018 Photo: Bob Bateman

Upwind—Helm working with the Main Trimmer

The Helm has a substantial advantage in knowing how to trim the sails, as he can feel the amount of weather helm (or lack thereof) in the tiller (or wheel). Often though, this advantage gets lost as:

- He does not communicate that feel to the mainsheet trimmer

- When he does, he does not communicate it properly

The Mainsheet Trimmer, in a perfect environment, should be responsible for the set up of the sails upwind (both Headsail and Main) and should be working also on how the Rigging should be adjusted. The Headsail trimmer is essential when setting up the Headsail before the race and should link in with the Main trimmer on this to get a right combination of trimming going. However, once the race starts, usually the Headsail trimmer is needed on the rail, leaving only the Main Trimmer and Helm sitting in. Therefore, the main trimmer also has to look at adjusting the Headsail as well, if needed. An example of this is in tacking. The jib trimmer winds in the headsail to what he/she thinks looks good. However, the boat is just building speed, so apparent wind is not entirely built when he/she hits the weather rail. Also his/her weight when it gets to the weather side, puts further power into the sails, opening the leech. This added to extra apparent windspeed, once the boat gets up to full speed, opens the jib leech even further. It is then the Mainsheet trimmers job to go down and check the jib, and often another wind on the winch is required.

Joker 2 going upwind. Helm and Mainsheet trimmer getting the cushy jobs. Photo: Bob Bateman

Joker 2 going upwind. Helm and Mainsheet trimmer getting the cushy jobs. Photo: Bob Bateman

Communication Between Helm & Main Trimmer: Upwind

A Non-communicative Helm is a big problem, as the mainsheet trimmer does not have the advantage of what the helm is feeling. On most boats when I am steering, the helm balance will likely tell me if I need more Power or less power. Typically, if my helm has more than 4 or 5 degrees of weather helm(see my tip on Figuring how much this is)(link to my top 10 tips upwind where I cover this), then my rudder is acting like a brake instead of a lifting foil. Then I will ask my Mainsheet person to either:

- ease mainsheet

- drop the traveller

- Add more backstay

So, which one? Normally, I go:

- Traveller down first, to a max of about a foot below centreline—any more and there is too much backwinding

- Backstay on further—to a max of when the Main is overbending and wrinkles from the middle of the mast to the end of the boom occur. Remember more backstay will open the main leech, so further mainsheet may then need to be pulled in. What you are trying to do is flatten the whole sail, but keep the leech still tight to aid pointing.

- Only when these two options are not enough, would I look at easing the mainsheet.

If the helm tells you he/she has no feel in the helm, then the Mainsheet persons job it to try and add power, generally to the Main, to get more bite in the helm. The opposite of the above is then the way,

- Traveller up—to a max of the boom being slightly above the centerline.

- Ease the backstay. This will power up the main, by straightening the mast. Always however keep a minimal amount of backstay on, to stop the Forestay pumping, as backstay tension has a significant effect on your forestay sag. Easing the backstay will tighten the main leech so will likely require an ease also on the mainsheet.

- Tighten the Mainsheet if above 2 items are still not giving the helm enough feel.

Mark Mansfield is communicating with Mike Evans (helm) on Big Picture at the 2016 Half Ton Cup in Falmouth

Mark Mansfield is communicating with Mike Evans (helm) on Big Picture at the 2016 Half Ton Cup in Falmouth

If the helm cannot work out which of these 3 to do, then the least he/she should say is—"I need more Power", or he/she should say –"I need less power". Then it is up to the Mainsheet person to try one of the 3 changes above. What he/she(helm) must not do is say nothing, and hope the mainsheet person picks up what is wrong. When I am on the main, I am always looking to see how much weather helm, or lack thereof, is evident and if I see too much or too little, I will ask the question of the helm. Watching the speed and wind angle on the clocks is also essential. If everything is good, the boat is fast and high, then the Mainsheet person should say that, as it is an excellent positive statement. If speed and height are not great, then the Mainsheet person should suggest a positive change, like, "let's try a bit more Backstay", or Maybe we might try footing a bit".

If the Mainsheet person, looking at the telltales, is seeing the helm is off the wind, he should immediately say it, as losing height, without much extra speed, is a real negative. On many boats, where I sail as mainsheet, I will regularly point out if I feel we are not sailing at the right angle. High concentration levels from the helmsperson are required all the time to ensure the boat is ideally on the wind and often that concentration can lapse a bit. It is the mainsheet person's job to watch for this and keep the helm concentrating.

Often during a long day, where up to 3 races might be sailed, it is worth looking at the helm handing over for some legs(maybe downwind legs later in the day), to keep concentration levels going on the upwinds. The best Helm/Mainsheet combinations are those that are continually talking together about speed, height and feel.

Communication Downwind

Unlike upwind, downwind is all about communication between the Helm and the Spinnaker trimmer. The Mainsheet person is usually a bit redundant as often, especially on dead downwind legs, the main goes out entirely and is not trimmed much. Downwind, the phrase: 'the Spinnaker Trimmer should be steering the boat downwind', is correct. He/she doesn't hold the helm, but they direct where the boat goes.

John Maybury's Joker 2 running downwind on the way to an overall win in Dun Laoghaire Week Regatta in 2017

John Maybury's Joker 2 running downwind on the way to an overall win in Dun Laoghaire Week Regatta in 2017

The Helm has some feel downwind, but nothing like what is being transmitted back to the spinnaker trimmer from the power coming through the spinnaker sheet. The Spinnaker trimmer must now be the communicative person. A quiet spinnaker trimmer is a slow spinnaker trimmer. He must boss the boat down the runs. He must be continually talking to the helm about depth and speed and calling the helm up and down. So, "up 5" or "down 5" are the sort of things you would expect to be hearing from the spinnaker trimmer every 10 or 20 seconds., meaning up 5 degrees or down 5 degrees. He/she will be doing this as pressure builds and drops on the spinnaker sheet. More pressure allows the boat to go deeper, less pressure, height needs to be the call to keep the speed on. As a general rule, the spinnaker should be steady, and the spinnaker sheet should have decent pressure. If it does not, then the spinnaker is not pulling the boat forward. The spinnaker trimmers job is also to call the trim on the guy(or on Asymmetric) and also the pole height. As a general rule, the pole should be at right angles to the wind, and in that scenario, the spinnaker luff should stand straight up, parallel to the mast, and curl in the middle. If the spinnaker is rolling to weather of the pole, the pole needs to come back. If the spinnaker is falling to leeward of the pole, the pole needs to go forward.

Often I find Spinnaker trimmers just pulling in and out the spinnaker sheet, without communicating where the helm should point the boat, or without trimming the pole backwards and upwards. It is the Spinnaker trimmers job to do all these things.

Fools Gold, during the IRC Worlds in Aug, VMG running with Mainsail and A2 Spinnaker, both from UK Sailmakers Ireland. Note many of the crew are forward of the mast

Fools Gold, during the IRC Worlds in Aug, VMG running with Mainsail and A2 Spinnaker, both from UK Sailmakers Ireland. Note many of the crew are forward of the mast

Conclusion

The feel upwind (on the wheel or tiller) or downwind (on the Spinnaker sheet )are extremely important and cannot be kept to oneself. Increase the communication levels, and in nearly all cases, the boat will go faster.

So, apart from the helm, if you have one particularly good sailor on the boat, by rights, for best speed, that person should trim the main upwind and the spinnaker sheet downwind. This is not always popular on boats wanting specific positions for the various crew. Also, often the mainsheet person might also be doing/helping with the tactics. When going downwind, calling where to go and where the pressure is, can be very important as well. All decisions to be made on a boat to boat basis.

Fair Sailing

West Cork native Barry Hayes took over the UK Sailmakers Ireland loft a year ago From Des McWilliam, having returned to Crosshaven from an international career in sailmaking. Afloat.ie asked him about his own sailing background and the changes he has seen in Irish sailing in his first year home.

Afloat.ie: You worked for Des McWilliam for five years at the Crosshaven loft from 1999 to 2003 before heading overseas. How was that?

Barry Hayes (BH): Well, there is no one better to learn from than Des. He was so well respected and his knowledge was outstanding. McWilliam Sailmakers was at its height in those years, I got a fantastic foundation on how to build sails. Although busy, it was still a small sail loft which gave me the opportunity to learn every aspect of sailmaking from start to finish. From simple tasks like cutting sail numbers (which is crucial for developing your scissors skills!) to joining panels and marking up sails, to putting the finer finishing details to patches and rings. It is often underestimated the time, attention, skill, and detail that goes into building sails - in those days it really was an art. Nowadays there is much more science involved, but the art is ever present, and its importance shouldn't be underestimated! It really couldn’t have been a better place to start my sailmaking career.

Barry Hayes, loft manager of UK Sailmakers Ireland at Crosshaven

Barry Hayes, loft manager of UK Sailmakers Ireland at Crosshaven

Throughout these years I also raced a lot of different boats from the famous Cracklin' Rosie to J24s and everything in between. Spending so much time afloat, while having such a large knowledge base to draw from at the loft, produced a rapid improvement in both my sailing and also sailmaking skills. You relate what you are doing on the floor to what you see in front of you afloat. Why this works better than that. Why we add depth in places and remove it in others, and how this is done by broad seaming and luff curve. Any question of trim, optimisation, or efficiency was answered at Monday morning coffee break - and there were plenty!

The 76ft maxi Jelik

The 76ft maxi Jelik

Afloat.ie: You moved to a new job in sailmaking in New York for four years until 2007. What did you do there?

BH: Moving to New York to work for UK NY was a huge step forward in every way. There the very first project I did was work on making traditional hand made sails for Lion's Whelp. It took us three months to make and hand stitch every seam. All the skills I had picked up in Ireland were tested and refined. Talk about out of the frying pan and into the fire!

Swan 45’s one design racing was big in the US at the time. I start racing on Devocen (pictured top), doing races up and down the east coast of the US, from Newport to Key West. It was non stop action and a great learning experience. Working in the loft all week then heading to Key West for a regatta was fantastic - the truest representation of the sailmaker's lifestyle. While in New York I started working for UK International developing our string sail production process called Ultra. This is where art met science head-on. This taught me the intricacies of how string sails are made and the technology behind them. This was right on the frontier of sailmaking at the time and being involved with it was an amazing experience; which would prove crucial in the future.

Traditional Schooner Lion's Whelp

Traditional Schooner Lion's Whelp

Afloat.ie: Then, you worked in Hong Kong for 14 years. Can you describe your role there?

BH: I started my job in UK Hong Kong as a sail designer and selling sails. Although in a familiar role; the culture and pace were intense in comparison to Ireland. I continued with this job for many years, progressing to a managerial role and working on some pretty big projects. Like China Team Americas Cup which was a huge technical learning curve. The loads and performance requirements for the IACC Cup yachts of the time were on a whole other level to anything I had experienced before - developing the technology required to satisfy them was quite a task. I was also heavily involved with Maiden HK which was a 115 Supermaxi. Which had the highest IRC rating in the world at the time. She was a truly one of a kind. I continue much of this work today with ongoing projects like Jelik a 76 ft Maxi and the China Cup which runs a fleet of 30 First 40.7s in One Design configuration.

Maiden HK a 115–foot Supermaxi

Maiden HK a 115–foot Supermaxi

One of the biggest projects I worked on while in Hong Kong was the development of our "Titanium" sail moulding system. It was a 5-year project focused on producing an innovative moulding and manufacturing process to produce high-performance sail membranes. Technically, it was a massive challenge. The experience I had gained from my time in New York and Ireland culminated in the Titanium development project. You can't simply jump into these things, it takes a lot of experience to push beyond what is known. Knowledge of sailing and sail design are crucial - you need to know what the end goal is - but knowledge of the technical processes of moulding, lamination, material interactions, and mechanical engineering was crucial. We were building machines that simply didn't exist. It was, and still is, a very exciting and absorbing project to be involved with. If you had told a teenage Barry Hayes from Schull that he would be developing performance moulded sail technology in Hong Kong in fifteen years time I can honestly say I wouldn't have believed you!

"If you had told a teenage Barry Hayes from Schull that he would be developing performance moulded sail technology in Hong Kong in fifteen years time I can honestly say I wouldn't have believed you!"

China Cup racing

China Cup racing

BH: Everything, literally everything, from Ruffians, J70, J80, TP 52, Kerr boats, Mills boats, Maxis, AC45. It was a real mixed bag with a lot of variety.

Afloat.ie: What are the biggest changes you have found since moving back to Ireland after 20 years abroad?

BH: Safety is one of the biggest changes I have noticed since I've come back. People wearing their life jackets and EPIRBs. These little things have really changed our sport and made it much safer here. When I think back to some of the offshore races we did in Ireland twenty year ago it boggles the mind to think about what we were wearing, or more to the point, what we weren't wearing!

The other main change I have seen is the lack of young people buying boats in the sport. This has to change in Ireland for it to be a sustainable sport going forward. It is certainly not an easy nut to crack. The appearance of many U25 teams in the past few years is a great initiative and more of the same can only benefit the sport.

China Team 1

China Team 1

Afloat.ie: In terms of sailmaking technology, what have been the biggest developments in the past few years, and are we seeing them in Ireland?

BH: Moulded sails is an obvious one - we are one of the only sailmakers making truly one-piece moulded sails. That is the entire sail structure formed on the mould, not panels which are formed on a flat surface and then joined on a mould. These performance sails are making their way into Irish waters, with many more on the way for the 2019 season. This, in turn, has improved longevity, stability and shape retention - their lifetime, shape holding over varying wind conditions, and how long that shape remains throughout its lifetime. Light sails that last a season is a thing of the past. In the past, an Americas Cup sail would go through 30 tacks and was then put in the bin. Those days are gone. Jedi, a Dun Laoghaire based J109, purchased a mainsail for their 2017 Fastnet campaign. The sail has seen 2 full seasons of hard offshore racing and particularly arduous Round Ireland and the sail shape is still as good as new.

Warship 36

Warship 36

Afloat.ie: And what of the future? What do you see as the future trends for Irish sailing over the next decade?

BH: Technology wise there is a lot happening here. We are continually testing new products in Irish waters which ultimately will develop worldwide. Last year we had a J109 test jib which spent a lot of time afloat both here in Ireland and on the South Coast of the UK. There was a J80 experimental jib which was afloat in Howth, and more recently a 1720 jib used throughout the DBSC Spring Chicken series in Dun Laoghaire. There will be more of the same this year. I will stay tight-lipped for the moment but it'll be hard to miss soon enough. Sail technology is always evolving and improving, you cannot stop it, and there is no point in keeping up - we're at the forefront and are taking Irish sailors there with us.

More generally, I can see one design making coming back. It ebbs and flows over the years but classes like the J80 and 1720 are great learning platforms and provide excellent racing. Boats like this are training ground for young sailors to learn how to sail and get into the sport. This year we have seen in bigger boats coming into the country - which hasn't been the case for some time. Hopefully, this will continue and return the Irish big boat scene back to where it once was.

UK Sailmakers Ireland Win Big Boat Sails Orders

Recent orders from some of Ireland’s largest racing yachts have made for a busy winter period for the UK Sailmakers Ireland team writes Mark Mansfield. Last year the Farr 43 “WOW” and the new J121 “Jackhammer” were feature boats for UK Sailmakers Ireland; both taking a full suit of Uni-Titanium molded upwind inventory, in addition to Matrix spinnakers and Code Zero and Flying Jib packages. The 2019 season brings further big boat customers to the team. Chief among the new additions is a new “WOW” – an XP44. She will be the latest addition to a long list of previous yachts of the same name. Based out the Royal Irish Yacht Club, the team are awaiting the imminent arrival of their new project and are very excited for the sailing season ahead.

“We are delighted to be involved with such a motivated and passionate team” - explains UK Sailmakers Ireland’s Barry Hayes – “these guys just love sailing. Whether it’s at the bar, on the dock, or out on the water, they give 100% all the time. Fun and just the right amount of seriousness. The most important thing is for the crew to enjoy the time afloat while going fast – that’s where we come in.”

The new XP44 will sport a Uni-Titanium moulded upwind inventory and Matrix downwind spinnakers off an extended fixed bowsprit. She will also carry furling masthead Code Zero and Uni-Titanium Flying Jib packages to improve her offshore and coastal racing prowess.

Sydney 43 "Christopher Dragon" with her Flying Jib deployed outside her J1

Sydney 43 "Christopher Dragon" with her Flying Jib deployed outside her J1

Also joining the UK Sailmakers Ireland team are the Dun Laoghaire based Beneteau 44.7 “Lively Lady” and Beneteau First 50 “Mermaid IV”. Lively Lady will fly an X-Drive Carbon upwind sail inventory. She will also carry a Code Zero package using an Ubi Maior top-down furler. Mermaid IV – winner of the 2017 Turkey Shoot – is kicking up a gear for her racing 2019 season. She has opted for a Titanium moulded mainsail and all-purpose furling jib. Her team has been extremely busy over the previous two months maintaining and upgrading her systems for the upcoming sailing season. Her energetic and social crew are counting the days until her rig is re-stepped and her new upwind package is put through its paces around Dublin Bay.

Mermaid IV returning from a trip around the Muglins during the 2018 Turkey Shoot series

Mermaid IV returning from a trip around the Muglins during the 2018 Turkey Shoot series

Down South in Kinsale – the Salona 45 “Meridian” has ordered a new X-Drive Carbon mainsail to accompany his X-Drive Carbon J3. Staying in Kinsale; the Beneteau 44.7 “White Tiger” has also opted for a X-Drive Carbon upwind inventory for his 2019 season.

White Tiger and Lively lady, both near identical Beneteau 44.7s have opted for a non-overlapping headsail setup in order to optimise their IRC ratings. This setup has been used to great effect on similar models such as 2017 RORC Yacht of the Year “Lisa”, skippered by Dun Laoghaire’s Michael Boyd.

Beneteau 44.7 "Lisa" with her non-overlapping headsail configuration

Beneteau 44.7 "Lisa" with her non-overlapping headsail configuration

As recently reported by Afloat.ie, Ireland’s newest addition to the J109 fleet, Richard Colwell and John Murphy’s, has also chosen to join the UK Sailmakers team. Outrajeous will also sport a Uni-Titanium upwind sail inventory and Matrix downwind sails. UK Sailmakers Ireland has run an extensive development programme with the Outrajeous team over the past four months. This programme will culminate in the delivery of her inventory in early April – after which the entire team will test, tweak, and refine settings to ensure she is at peak performance for the 2019 season. The entire UK Sailmakers team has been busy over the winter months. 2019 marks the second full year of operation since Barry and Graham took over the sailmaking dynasty from Des McWilliam.“We are delighted with the new additions to our growing customer base” - says Barry Hayes, commenting on recent developments - “The ‘sails’ market is a very competitive environment and we are attracting some of the best boats around to join our team and represent our brand. Our product range is both affordable and versatile to match the needs of all sailors, and our wealth of experience at all levels of sailing enables us to fulfil our customers’ requirements with pinpoint accuracy.”

L-R The UK Sailmakers Ireland team of Mark Mansfield, Graham Curran, and Barry Hayes aboard "Outrajeous" during December testing

L-R The UK Sailmakers Ireland team of Mark Mansfield, Graham Curran, and Barry Hayes aboard "Outrajeous" during December testing

“Having Mark Mansfield as part of the team is plus for our customers” – comments Graham Curran - “as an Olympian, Mark’s knowledge of performance racing is unquestionable. This is of huge benefit to our customers for getting their boats and sails to absolute peak performance. Sharing this knowledge with sailors throughout the country is very important to us as a company. Our educational and instructional article shared through Afloat.ie have been very well received and will be available to sailors for years to come. "We have a busy season ahead of us looking after our customers, both old and new. Our job is to ensure they are enjoying their sailing to the fullest. The time we get to spend afloat these days is short – you need to make the most of it. We provide an unparalleled professional service backed up by operational manufacturing and servicing sail loft and an experienced passionate team.”

UK Sailmakers Ireland: Top Tips for Headsail Trim

The headsail trimmer is a crucial member of a boat’s “speed loop” along with the mainsheet trimmer and the helm. But often headsail trim is overlooked and is reduced to “pull it in and hike” mentality. Without good headsail trim, you will be going very slow, or simply not as fast as you could be. In this article, Graham Curran of UK Sailmakers Ireland takes us through his top 5 tips for headsail trimmers.

For this top tips article, we are going to focus on the headsail trimmer on a keelboat with a non-overlapping jib setup.

I recently had the chance to back over the footage of Fools Gold’s IRC European Championship and IRC/ORC World Championship campaign during the 2018 season, skippered by Robert McConnell of WHSC. My primary role aboard the boat was primary trimmer (T1 / Trim 1) – headsail trim upwind and spinnaker trim downwind. Pressure events like European and World Championships are all about the small details – good hoists and flawless tacks were not racecourse gains in these fleets, they are the minimum requirement to be on the pace.

I’ve trawled through our footage to find examples of the crucial big picture and little tweaks needed to be an effective trim one. We won’t go too deep into the technicalities of sail setup for different conditions, rig tune, car positions, or twist control. We’re looking for the simple things that lead to big gains. To help you do your part to improve the overall performance of the boat. This article is by no means exhaustive – see below my top five tips for headsail trimmers.

TIP ONE – INHAULERS DURING PRE-START

When you are manoeuvring during the pre-start make sure your inhaulers are fully off. Inhaulers are a great tool for improved trim, but only when sailing fully upwind. When reaching or bearing away during pre-start it is important to keep the boat at maximum power and speed (when needed). If you inhaulers are on your jib will twist open when the sheet is eased, but the inhauler will hold the clew inboard, leaving the bottom of the sail over trimmed. Leave those inhaulers off and increase the reaching power of your headsail. Pull them back on to your marked upwind setting on your final approach to the line.

TIP TWO – WATCH THOSE TELL TAILS!

... but not the ones you may think. The headsail luff tell tails are a great indication of where the sail is in terms of power and car position, but the leech tell tails are absolutely crucial as they show how close you are to max trim when sailing upwind. Unlike the mainsail, where some stall is good, we want as little stall as possible on the leech of the jib, but we want to be right on the edge, as close to stalling as possible. Our leech tell tails are the best indicator of this.

Generally, your top leech tell tail will stall first. Trim the sail in using your sheet until the top tell tail starts to fall in behind the leeward side of the sail. It is actually being sucked into the leech by the air separating off the leeward side of the sail. Once you have this stall ease the sheet a touch to get the tell tail flowing again. 95% flying with a 5% stall is a good indicator that the jib is fully trimmed in average conditions.

If the conditions allow it, stay to leeward and check this constantly. If the breeze drops the sail will stall and the sheet will need an ease. If a puff hits the sail may become under trimmed and will need a squeeze on the sheet, always looking for that little bit of stall.

TIP THREE – HELP YOUR HELM, BACK THE JIB

In light airs tacking is expensive. Reducing the pain as much as possible is key. This is why we roll the boat and try to use as little rudder as possible. Do your part by holding the headsail on the windward wise for 2-3 seconds after the boat has passed through the wind. The sail will fill on the windward side and help the bow come around. Release quickly and snap it in on the new side. This will give instant power to the helm coming out on the new tack.

It is important to discuss this with the helm and be consistent. The helm will become used to having the small back of the jib to help him, he will use less rudder to turn the boat as he knows the jib will help, and the boat will lose less speed as a result. If you suddenly decide to not back the jib he will then overcompensate with more rudder – and likely give you an earful.

It is also helpful to count into your release for your second trimmer, so they can quickly snap in the jib on the new side. Entering a tack is usually say “small back” or “big back” and count “2 … 1 …” as the jib fills on the weather side.

TIP FOUR – KNOW YOUR SAILS, KNOW YOUR SETTINGS

Many boats sailing inshore with non-overlapping headsail setup regularly use up to three headsails. It is vital that you have go-to settings for each sail. I assign a colour to each sail, green for J1, blue for J2, red for J3. I then whip a mark on my jib car adjustment line in each colour, on both sides, so I have a good starting point for each sail. This is particularly helpful if you have been reaching and the car went forward, or if the wrong rope was uncleated at the windward mark, you have a quick reference point in the cockpit go to.

This can also be done with the jib halyard jib by having a scale on the deck in front of the halyard clutch. Put a white whipping on the halyard at the middle of the scale when the sail is hoisted hand tight. Set the sail to good halyard tension (looking at the draft position of the sail) and mark the scale with the sail’s corresponding colour. The sails luff lengths, particularly the J3, could be different so keep this in mind when laying out your scale.

These will give you a solid and consistent baseline to work from for each sail, which can be tweaked for the conditions of the day. Update each of these as your find good settings and as your sails, halyards, ropes change.

This will also make your skipper very happy as the day you cannot make it for sailing doesn’t mean that the headsail trim falls apart. Anyone can step in and use our basic settings as an immediate guide for good trim.

TIP FIVE – DON’T OVER EASE ON THE SPINNAKER HOIST

Your last job at the top mark before switch to spinnaker trim is to ease the jib for the bear away. This is extremely important and has roll on consequences for the entire crew.

Do not over ease the jib sheet. The sail needs to be eased just enough for the top to twist open and depower the boat so the helm can bear away. Usually 8/9 inches of sheet is enough. If too much is eased there will be a large space between the leech of the jib and the back of the main. The wind will blow through this gap and suck the spinnaker, now being hoisted, into it, filling it prematurely. This will make your mast man and pit person very angry.

By having the jib trimmed in a little it also sucks the spinnaker onto the back of the sail, allowing it to go up the back of the jib and not fill prematurely. Once you get used to this smaller ease you will be able to move straight to your spinnaker sheet and be ready for the fill once the jib is on deck. It also has the added advantage of making life on the point end a little easier as the jib will be less likely to go over the leeward rail.

If on a spreader leg or in bigger breeze it is ok to ease the jib to allow the boat to bear away and be at max speed for the leg (don’t forget to ease those inhaulers) but trim is back in a bit before the hoist to close the gap. Remember you are in no rush to get to your spinnaker sheet, it isn’t going to fill until the halyard is up fully and the jib is coming down, provided you’ve done your job right!

CONCLUSION

Doing the simple stuff right makes a big difference across the race course. Take these tip aboard and put them into practice next time you are on the water.

IRC 2019 – Take Full Advantage of Changes to the Rating Rule

IRC is an ever-changing rule, adapting as our sport evolves at both the Grand Prix and club racing level. At UK Sailmakers Ireland we are always searching for advantageous gains for our customers. With a new year comes an amended IRC rule. Below we go through some of the changes of note (full details available from the IRC website) and give some advice on how to take full advantage of the rules without finding yourself on the wrong side of them.

Links for referenced documents for ease of use:

2019 IRC Rules and Definitions

Racing Rules of Sailing 2017-2020

World Sailing Offshore Special Regulations

IRC 2019 – Spinnaker allowance

The IRC rule rates every boat with an assumed number of three spinnakers on board while racing. Should a boat wish to carry a forth spinnaker, a particularly popular option for offshore races, there is a penalty (usually one point) applied to their IRC rating.

Under the 2019 rule, a boat may declare that they only carry two spinnakers aboard while racing for a rating reduction (assumed to be one point).

Currently IRC Rule 21.6.1 describes how boats will be rated for carrying more than three spinnakers on board. The rule does not explicitly state that they should not carry more spinnakers than declared on their certificate. In addition, whilst three spinnakers is generally considered to be a minimum number for boats competitively racing, it does not consider that a significant number of club level boats only use 1 or 2 spinnakers. Feedback from the owners of these boats shows that they feel at a disadvantage as they have a reduced sail inventory and are not able to compete. To encourage boats within this sector of the fleet it is proposed to allow boats to declare that they will carry a number of spinnakers less than 3. This will open up the possibility for the technical committee to consider a rating decrease for either 1 or 2 spinnakers on that basis.

Rule 21.6.1

2018: Boat carrying more than three spinnakers in total on board while racing will incur an increase in rating.

2019: Boats shall not carry on board more than the number of spinnakers on their IRC certificate while racing.

This change makes it clear that the maximum number of spinnakers that shall be on board while racing is as per your IRC certificate. It also allows a boat to consider an advantageous rating decrease for using less than 3 spinnakers. If you wish to change the number of a spinnaker on your certificate you can do so on your 2019 revalidation after having your sails remeasured in our IHC approved sail loft.

With the above in mind it is also important to consider rule 21.1.5.d:

(d) During a regatta run on consecutive days, including any lay days, the sails on board shall remain the same and be on board for all races. This Rule may be amended by Notice of Race.

You could have five spinnakers to choose from for a week-long event but the sails you use for day one must be the same sails used on day five. Hot swapping sails depending on the day's conditions is not allowed – unless explicitly stated in the event Notice of Race or Sailing Instructions. If you damage a sail beyond repair consider point f:

(f) exceptionally, in the case of significant damage or loss, sails may be replaced with similar sails. A Notice of Race may require that boats obtain permission from the Race Committee before replacing a sail. This Rule may be amended by Notice of Race.

Crew Positions & Lifeline Deflection

Hiking is extremely effective in terms of generating righting moment and boat speed. According to Farr Yacht Design; in general terms, crew weight hiking is approximately 1.45 X as effective as bulb weight, so adding one 80 kg crew member is similar to 116 kg on the bulb. This means that crew weight is more “efficient” when considering righting moment versus displacement. As such it is important to clearly define what constitutes hiking and what doesn’t.

22.6.1 RRS 49.2 is modified by deleting “sitting on the deck” in the second sentence.

The IRC rule change removes the ambiguous term “sitting on the deck” while maintaining the original intention of:

- When there are two lifelines, competitor facing outboard with their waist inside the lower lifeline may have the upper part of his body outside the upper lifeline.

- Lifelines shall be taut (by the OSR definition).

With hiking now clearly defined – what exactly is a ‘taut’ lifeline?

This is a point which raises some debate – likely due to the digging required to actually find the definition.

Loose lifelines are a major advantage when hiking. It allows more bodies to project further outboard, increasing righting moment as a result. Having the lifelines as loose as possible, without breaking the rules, is critical. So what is the definition of taut?

Lifeline deflection specified in the Offshore Special Regulation 3.14.1.i is as follows:

- When a deflecting force of 4 kg (8.8 #) is applied to a lifeline at the midpoint of the longest span between supports that are aft of the mast, the deflection shall not exceed:

- 50 mm (2”) for an upper or single lifeline

- 120 mm (4 ¾”) for an intermediate lifeline

So when a 4kg weight is applied to a lifeline it must not be deflected more than 120mm from the straight line between its two support stanchions. This should be done between the two stanchions aft of the mast with the greatest distance between them ie. The longest part of the wire.

There are some, shall we say, creative solutions to bypassing this rule. These are under investigation by rating/rules authorities to determine their legality.

With equipment inspections likely to become more common in Irish sailing, in the interest of fairness, it is best to be within the OSR lifeline definitions. The looser the better for hiking – but not so loose that you land yourself in hot water!

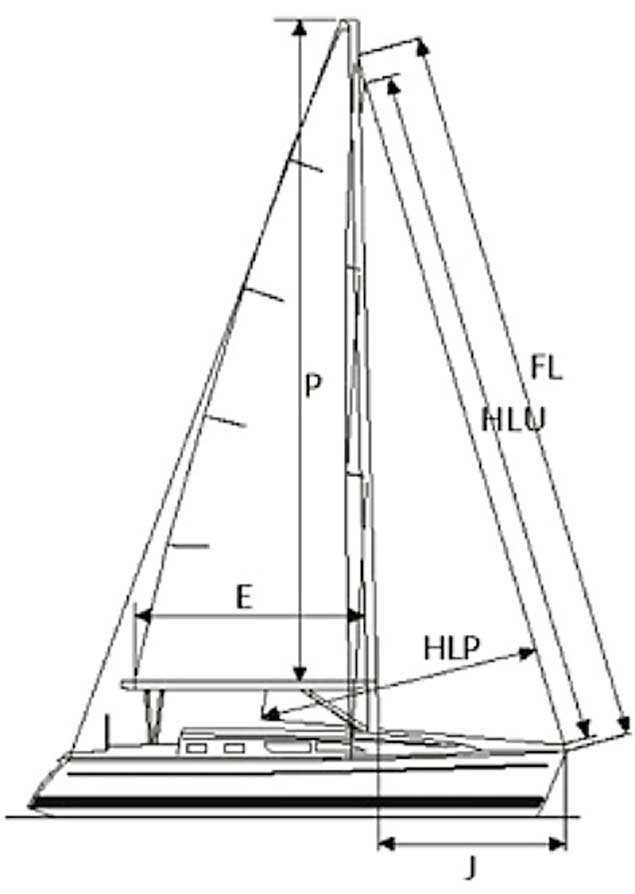

P & E Definitions – Confirm your black bands!

A boat’s P is the maximum allowable mainsail luff length. A boat’s E is the maximum allowable mainsail foot length. These are generally known as your “black bands”. The 2019 IRC rule clarifies the definition of both measurements. This is for the benefit of measurers and sailmakers rather than the sailor. However, what is of particular interest to the sailor is that if there are no black bands on the mast or boom then the extremities of the spars will be measured.

P: “If there is no upper limit mark (black band) the upper measurement point shall be taken as the top of the highest sheave used for the halyard.”

E: “If there is no outer limit mark the outer measurement point shall be taken to the aft end of the boom.”

Check your black bands versus your certificate and sails. If they are not marked already be sure to do it to avoid being caught out at a later stage. If you sails are smaller than your defined black bands you may be able to reduce your P & E measurement for a rating advantage.

Remember – your P & E measurements come from your mast, they are not measured from your mainsail. Mainsails are built to be within the bands. The bands define the mainsail, the mainsail does not define the bands.

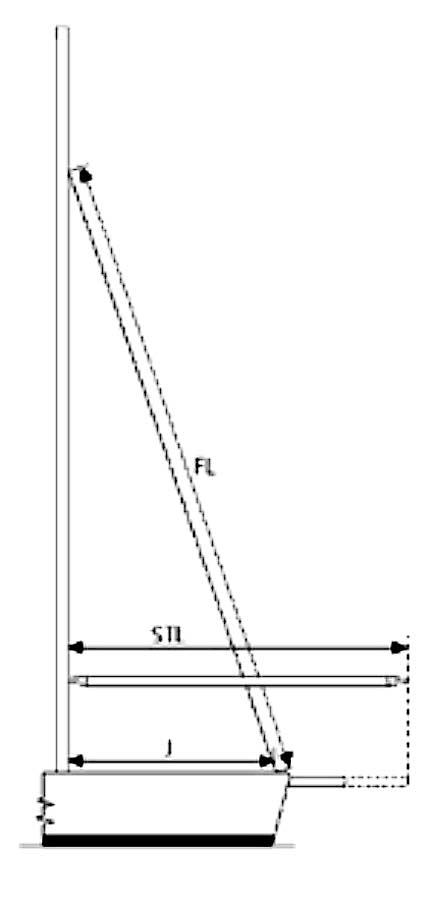

STL Measurement – How long is your pole?

Similar to the P&E definitions above – the STL definition has been amended to improve clarity.

IRC definition STL addresses horizontal spinnaker tack point distance from the mast. The current rule does not make it clear that the spinnaker pole track and any fittings to the mast should be ignored in the measurement of STL. The current rule does not make it clear that bowsprit outer limit marks should be ignored in the measurement of STL.

It is therefore proposed to amend IRC definition STL to make it clear that fittings on the mast and bowsprit outer limit marks are ignored when measuring STL.

Amend STL definition as follows:

Amend STL definition as follows:

The greatest horizontal distance from the forward face of the mast spar, ignoring any fittings and tracks, measured on or near the centreline of the boat, to any of the following:

- the extremity of the spinnaker pole, whisker pole or bowsprit, ignoring any outer limit marks;

- the spinnaker tack point on deck projected vertically as necessary;

- if a headsail may be tacked forward of the forestay, the headsail tack point on deck projected vertically as necessary or to the extremity of the bowsprit.

The pole track and any fittings at the mast are ignored when measuring a boats STL. So your STL is clearly defined as the measurement from the front face of your mast to the outmost extremity of the pole, rather than the length of the pole itself. This is worth checking to ensure your certificate is accurate.

Single Furling Headsails

The definition wording for furling headsail has been updated to ensure the rule is restrictive as intended.

IRC rule 21.8.1(c) defines how a furling headsail is used. In the rule restricting the use of headsail to be not less than 95% of HSA there is a permissive “may” when the rule actually requires a restrictive “shall”.

Amend Rule 21.8.1(c) as follows:

Only a single headsail shall be used while racing, whose HSA may shall not be less than 95% of rated HSA except that alternatively a storm jib (see Appendix 1) may be used.

The change makes it clear that using a furling headsail of not less than 95% of the rated HSA is a requirement.

Other Changes and Clarifications

The remaining changes for the 2019 IRC rule are general clarifications on definitions or additional rules for Grand Prix racers. For example – a rule has been added to rate all boats with systems to adjust their forestay’s while racing. There was also a small change in the rig factor definition for clarity and to better reflect current rating practices.

Conclusion

Staying up to date with the IRC rule is critical for optimum performance at our national regattas. The offseason is the perfect time to confirm and check measurements, tinker with lifeline tension, and renewing your sail measurements to ensure you are being fairly rated. Do all of this and you will be ready to hit the ground running come Spring.

As always our doors, phones, and email are always open to offer advice and guidance.

There was a full house to hear solo sailor Tom Dolan outline his 2019 plans in the new foiling Figaro 3 at Kinsale Yacht Club last Thursday.

As Afloat.ie previously reported, the evening also featured Mark Mansfield from UK Sailmakers Ireland present slides on his recent top tips articles on Afloat.ie. It was an engaging session that produced a half hour of questions and answers.

Other similar club events from UK Sailmakers are planned over the next few months.

Top Tips to Prepare Your Race Boat for the Season

Following on from his top tips articles for upwind and downwind helming techniques, UK Sailmakers Ireland agent and sailing professional/coach Mark Mansfield gives tips for prepping your race boat for the sailing season ahead.

Tip #1—Improve Bottom Finish

So many boats I have sailed on last season have bottom finishes that would range from average to poor. A poor bottom finish likely costs up to 2 % in speed at least which is 72 seconds an hour. Grand Prix boats will spend weeks prepping and fairing their bottoms and foils. This is over the top for Irish racing, but a very smooth bottom finish is easily achievable with a bit of time and effort.

Spraying two or three coats of hard antifouling, like Nautix, on a smooth sanded bottom would be best, then allowing it to harden for a few weeks, then sanding it back with a light 600-grade sandpaper will get a great finish. Even applying it with a very good roller will work nearly as well, especially if you sand it afterwards.

Cruiser Zero campaigner Jump Juice gets her bottom prepped by Colm Dunne of Yacht Services Ireland Photo: Facebook

Cruiser Zero campaigner Jump Juice gets her bottom prepped by Colm Dunne of Yacht Services Ireland Photo: Facebook

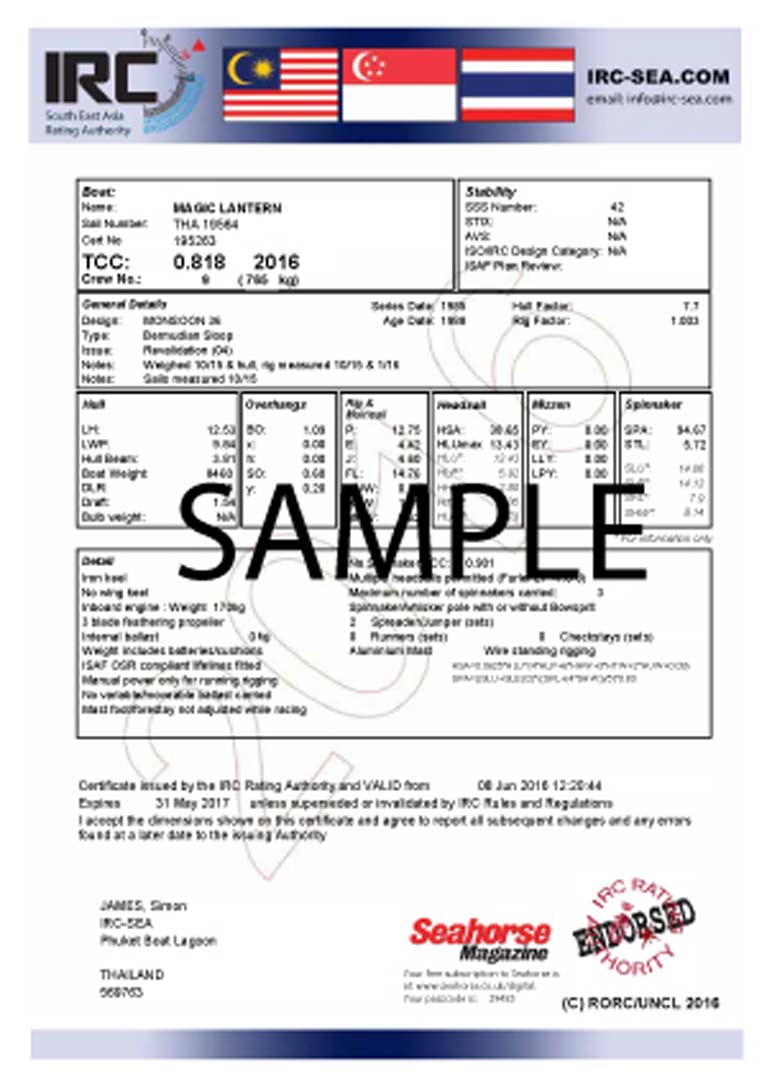

Tip #2—Get Sails Remeasured

If you sail IRC, your largest sails should be remeasured reasonably regularly, as sails shrink, particularly headsails. Most of this shrinkage happens in the first few months when new, but it is not unusual for a boat to drop two points or more in rating, after remeasuring, which is a gain of seven to 10 seconds an hour. Jib luff lengths and both Jib and mainsail girths regularly drop in size. Spinnakers rarely shrink, so best to just do the largest upwind sails. Dropping the sails into your sailmaker is well worth the effort and relatively small cost and the sails can also be inspected at the same time. UK Sailmakers are an In-House Certification (IHC) sail loft so your sails are endorsed and measured by certified IRC - ORC and ISAF professionals. Contact UK Sailmakers (details at the foot of this article) if you want to organise to get your biggest sails remeasured.

Tip #3—Upgrade Running Rigging

So many times I go aboard boats when tuning their Rig or doing some Coaching and I find halyards and Sheets not fit for purpose. In very many cases the halyards are too stretchy, are oversized and heavy or are hard from salt and UV damage. Likewise with jib and spinnaker sheets. Rope technology has moved forward a lot in recent years and keeping weight out of the top of the mast is a priority. If possible, backstays can be changed from wire to Dyneema, large main halyards can be changed to a lighter 2:1 alternative. Heavy metal shackles can be changed to light soft shackles. Never knot a jib sheet or halyard as they will break easier and because it is a knot it is hard to reproduce settings later. Specialist Rope providers such as Rope Dock in Dublin can easily customise an updated package for an owner.

A comparison of a replacement 8mm Halyard for a 10mm old halyard (red) prepared by Dublin firm Rope Dock. The new rope has less stretch and is significantly lighter

A comparison of a replacement 8mm Halyard for a 10mm old halyard (red) prepared by Dublin firm Rope Dock. The new rope has less stretch and is significantly lighter

Tip #4 – Make Sure Spinnakers Are Fresh

You might say, as an agent for UK sails, I would say that. But the reason I particularly pick out spinnakers is when a spinnaker gets a year or so old, it starts to lose its shiny, waterproof finish. This then means the spinnaker is always heavier, with salt and moisture, which means it does not fly as well.

In addition, because it is not that shiny, it is harder and slower to launch. An asymmetrical sail, in particular, is affected even more, as each time you gybe them, they take an extra few seconds to set, while the spinnaker slides across itself.

One design sailors will always try and get a new spinnaker each year, even if the shape of the old one is still pretty good. If not getting a new sail, at least wash it well during the winter, and if possible coat it as much as you can with a lubricant like McLube. This will certainly improve it.

McLube dry lubricant spray—great for improving an older spinnaker

McLube dry lubricant spray—great for improving an older spinnaker

Tip #5 – Buy Racegeek or Volicetek Prostart Type Start Line GPS Device

Trying to figure out how close you are to the line is a nightmare. For those who sail at a top level it gets a bit easier, as you get used to it, but even still it is a challenge. I will always suggest to an owner to buy one of these types of instruments. In particular, it allows you to push the centre of the line, and get a great advantage as often there is a bow in the line midway down, which can allow you to get a jump on the boats around you if you are right on the line. You just ping both ends before the start and the device will tell you the rest.

In recent years, these devices have become even more sophisticated and can interface with a boats normal instruments, like the Irish designed Race Geek, Marketed by Ric Morris from Dublin. This Racegeek was on the winning J70 at the J70 worlds in 2018. The second advantage of these devices is they also act as a backup for your Normal instruments as along with starting options, they will have speed, heading and a lot of other information.

A mast mounted Race Geek instrument shown working on a 30 footer

A mast mounted Race Geek instrument shown working on a 30 footer

Tip #6—Look at Optimising Rating

Most boat owners at this time of the year just renew their IRC rating, look at the TCF compared to last year and that’s it.

There are a host of things that can and should be looked at. It is not unknown for there to be inputting errors and if it happens that yours was input incorrectly the first day unless it is pointed out to the Rating Office, it will stay incorrect.

Sailmakers have access to a database of all the sail measurement data for all IRC boats, so can compare your boat's figures to other similar designs to see if there are differences.

In particular, they can look at successful boats within a design and see where they are different and give you the option of duplicating this.

For owners who may think of changing a boat from overlapping headsails to non-overlapping Jibs, all this very often can be seen from other owners who have already done this, to see if it was a success.

The bottom line is to consult your sailmaker who not only has a wealth of knowledge but also has IRC data that he can use.

A sample IRC Cert

A sample IRC Cert

Fair sailing for the season.

Mansfield & Dolan Team Up for Kinsale Yacht Club UK Sailmakers Talk

Cork Olympian and sailing professional Mark Mansfield from UK Sailmakers will be giving a talk at Kinsale Yacht Club on helming and sail trim tips on Thursday 17th, January at 8 pm.

Mansfield will be joined at the club by Figaro sailor Tom Dolan from County Meath who will give an insight into this season's plans for 2019 in his new foiling Figaro 3.

In his talk, Mansfield will refer to his recent popular articles on Afloat.ie where he gave tips for upwind and downwind sailing as well as rig set up advice.

Helming Techniques: Top Ten Tips for Downwind Sailing

Olympic Helmsman Mark Mansfield, who is a Consultant for UK Sailmakers Ireland, gives his ten top tips on sailing fast – and in control – downwind. This article follows his previous tips on upwind helming

Tip #1 Downwind steering in strong winds, while running, can be a challenge, the big worry is broaching. Broaching up to windward is one thing, but the Chinese Gybe broach is the really frightening and sometimes dangerous result. Older IOR style boats love to roll downwind and this Chinese Gybe can often occur. To try and reduce this happening, first try and ensure you don’t have too much power on the windward side while running. That means leave the pole forward a bit, oversheet the spinnaker sheet, maybe keep your crew on the leeward side. Also, it is very important to have your Vang (kicker) tight, because if not the balance of the boat is too strong to the windward side, where the spinnaker is.

Fools Gold, soon after a hoist on her way to winning 2017 Sovereigns week. Wind is already around the other side of the main so the dreaded Chinese Gybe is coming

Fools Gold, soon after a hoist on her way to winning 2017 Sovereigns week. Wind is already around the other side of the main so the dreaded Chinese Gybe is coming

Lee helm is the big issue in these conditions and the big mistake, when you feel lee helm, is to react by continuously applying further lee helm pressure as, eventually, the rudder will stall, and the Chinese broach is then inevitable. Best, when you feel this lee helm becoming very heavy, is to pull the helm the other way for a second, which allows flow to attach again to the rudder, then push the helm hard. This is best practised outside of a race first to get used to it.

Tip #2 Gybing in strong winds. This is another worry for many helms and it shouldn’t be that hard if you prepare. Always make sure you have, what will be your new sheet, well strapped down before the gybe. If you use twinning lines, get them fully down. This means you don’t come out of the gybe with your spinnaker all over the place. Try and pick a moment to start the gybe when the helm is fairly neutral. If possible do the gybe on a wave, as the boat is steadier at speed when the apparent wind is less. Then move the helm and get the mainsheet man to whip the main over. Important after the boom gets to the new side that you have adjusted the helm to approximately where you expect the new gybe angle to be. If the boom hits the new side before you get to this, you are in danger of a Chinese Gybe again. After the gybe, and before the pole gets set, if the spinnaker makes a big swing to windward, follow it with the helm, otherwise, the balance of the boat could get too strong on the windward side.

Going downwind in big winds

Going downwind in big winds

Once settled after the gybe, if the spinnaker is rolling around and you are struggling to control it, use these methods: If the spinnaker is rolling left, steer left. If the spinnaker is rolling right, steer right. Always follow the spinnaker in the roll.

"If the spinnaker is rolling left, steer left. Always follow the spinnaker in the roll"

Tip #3 When hoisting, especially in stronger winds, going onto a run, Initially bear away hard, but not to a fully downwind state. Remember the spinnaker won't fill until you can get wind into it, so bearing away to a broad reach first is best, then when the wind fills the spinnaker around the forestay (hopefully the pole is being pulled back) it should fill with a big swoosh. As you are not fully downwind, then the risk of a Chinese Gybe is not as strong. Once it fills, then slowly bear away to the near running angle that is best for Velocity Made Good (VMG), all the time ensuring that the items mentioned in Tip No 1 above are adhered to.

Kieran Collins's Olsen 30 going downwind in strong winds Photo: Bob Bateman

Kieran Collins's Olsen 30 going downwind in strong winds Photo: Bob Bateman

Tip #4 Similar to Tip no 1, broaching to windward when reaching can be reduced if you don’t allow the helm to stall. So, let us say you are reaching with the pole near the forestay, and you get a gust. The boat heels, your trimmer tries to ease the mainsail and spinnaker a bit, but she still feels like she is going to lose control and broach to windward. Much of this is caused because you will be continuously applying additional helm as the gust hits. If you get to the stage that is is going to happen, centralise the helm a bit for a second or so. Then try and pull her away again fairly aggressively. This allows flow to attach again to the rudder and the second effort may now be successful. If it is not successful, and it does broach up, then ensure you centralise the helm again. This allows the boat to bear away while the sail is flapping as the flow will again have been attached to the rudder. The biggest mistake with helms, especially when using a wheel, is they keep progressively adding further helm, and when the boat broaches, they then keep the helm hard over. You must centralise it and get the flow back.

"In light airs, getting the right downwind angle is all important"

Tip #5 In light airs, getting the right downwind angle is all important. Go higher and you will go faster but will take a longer route. Go lower and you will slow, but it is a straighter route. The best VMG is normally achieved by the angle where your spinnaker sheet just ceases to be floppy and tensions up. That is why the spinnaker trimmer, in reality, should be the main person to dictate how the Helm drives the boat downwind. He must continuously be talking to his helm and when he feels little pressure in the sheet, he asks him to come up closer to the wind. When he feels a lot of pressure in the sheet, he asks him to come down.

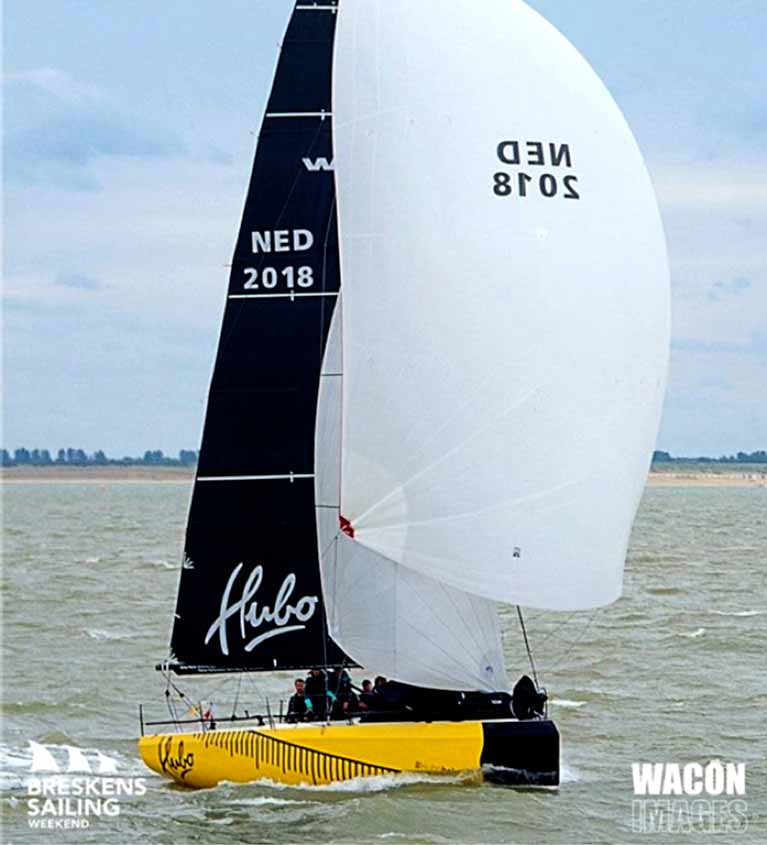

Hubo, with full Uk Ireland Mainsail, Spinnaker and Staysail set, during the IRC Worlds in August

Hubo, with full Uk Ireland Mainsail, Spinnaker and Staysail set, during the IRC Worlds in August

The J109 Something Else on a close reach under spinnaker on Dublin Bay Photo: Afloat.ie

The J109 Something Else on a close reach under spinnaker on Dublin Bay Photo: Afloat.ie

Tip #6 I mentioned VMG above. Most instruments systems allow you to put VMG up on a readout, if you want it. The information VMG uses is our masthead wind angle and boat speed to work out your fastest angle. Going upwind VMG will be all positive, as you are trying to head to the wind. However downwind VMG will always show negatives, as you are trying to head away from the wind at the fastest angle. Upwind VMG is not very accurate, as VMG does not take into account leeway, so upwind the fastest VMG angle on the instruments always seems to show powering off at speed as the best option. However powering off at speed causes a lot of leeway, and this powering off option does not reflect this on VMG. If upwind, you try and sail very high, your VMG readout will not look as good as the powering off option, but normally it is the better option.

Fools Gold, during the IRC Worlds in Aug, VMG running with Mainsail and A2 Spinnaker, both from Uk sailmakers Ireland. Note many of the crew are forward of the mast

Fools Gold, during the IRC Worlds in Aug, VMG running with Mainsail and A2 Spinnaker, both from Uk sailmakers Ireland. Note many of the crew are forward of the mast

That brings me back to using VMG downwind. As you are not heeling much when running, then VMG on your instruments is quite accurate. So you can try different levels of sailing deep to see which one is giving the Best(negative) VMG figure. Remember though, Your instruments need to be reasonably calibrated to make this work for you.

Running downwind in light airs on the Beneteau 31.7 Levana Photo: Afloat.ie

Running downwind in light airs on the Beneteau 31.7 Levana Photo: Afloat.ie

Tip #7 When Running downwind in light airs, try and keep all the weight out of the stern. Even the helm should try and move forward as far as he/she can. There is a lot of wetted surface area in the stern of a Yacht that will slow the boat down if it is allowed to connect with the water, especially in sloppy, wavey conditions. Remember the sterns of boats are designed a bit wide to give you stability in stronger winds. These sterns are also designed for speed in lighter airs, but only when the larger bit is out of the water. Too often I see large numbers of crew sitting in the cockpit downwind in light airs. They should be up as close to the mast and shrouds as possible to get the stern out of the water.

Tip #8 Unless there is a tidal reason or you are expecting a wind shift, or you are expecting more wind on one side, it is normally better to go down a run, initially, on whatever is the gybe that gets you closest to where you want to go. Going out to one side for a while, gybing and then having the long leg down to the mark rarely works. This is because if there is a wind shift down the longer leg, you have no room to gybe because you are effectively on the layline. Also if a gust comes in, which might allow you to sail deeper, there is no benefit if you are already on your lay line.

J109 Joker II in the 2017 Dun Laoghaire Regatta with the author on the spinnaker sheet. Photo: Afloat.ie

J109 Joker II in the 2017 Dun Laoghaire Regatta with the author on the spinnaker sheet. Photo: Afloat.ie

As a result of the boats that gybed earlier and are in the middle of the course, can get an advantage from either a wind shift, by gybing, or can also get an advantage from a gust by being able to run deeper than you can.

Tip #9 Always, while going upwind, be thinking about your next downwind. Which is the gaining downwind gybe?, what side did I take down the spinnaker?. Do I need to change it to the other side?. Likewise going Downwind, you need to be thinking which side do I take down the Spinnaker to make sure it is on the correct side to be ready for the next likely downwind. Often, It is better to go through an awkward windward or leeward spinnaker takedown, to ensure you don’t have to send people down to leeward while going upwind to change the spinnaker gear around.

"Being able to gybe quickly cannot just save time, it can actually make you faster"

If in doubt, always take the spinnaker down on the port side, as most windward marks are port rounding and mostly they are bear away sets. Also if in doubt, always bear away at the top mark and go on for a short while at least, in order to get you clear of the bad wind that always is a feature at a windward mark. To gybe early onto port, puts you into this bad wind and also puts you at a disadvantage as the Give way boat(as you are on port Gybe). My Normal practice is to get around the top mark, try and keep my wind clear of the next boat, but still go as deep as I can. Then after a minute or so, if boats are pushing up into your wind and if a gap appears to leeward, then a gybe to clear your air for a minute or two can be a good option. You can come back on Starboard after that, leaving all the guys to the right to mess each other up. It also sets you up to the left of most of the fleet, so if port gybe boats come across, they have to give way to you who are now again on starboard. The key to all of this is always after rounding to set up immediately for the gybe. This must be happening straight away after the spinnaker hits the masthead, even before the Jib is fully down.

Tip #10—Practice, Practice, Practice. Being able to gybe quickly and efficiently cannot just save time, it can actually make you faster. On most boats up to about 40 feet, roll gybing (crew moving in unison all from one side to the new weather side) can see you coming out of the gybe as quick as when you go in and because you are turning the boat downwind, you improve VMG while the gybe is happening. Also being able to Gybe quickly allows you tactical choices that you might not have if you are slow at gybing. A good practice routine is to round a weather mark without a pole, get the spinnaker filling by holding out the weather guy by hand and then roll into a gybe in a matter of seconds, setting the sheets so that it stays filling all the time. Then do a series of Gybes, preferably roll gybes, without any pole. This teaches everyone the importance of correct weight positioning on the boat and the importance of Steering through the Gybe onto the new correct angle.

Fair Sailing, Merry Christmas and Happy New Year

Cruising Sails – What's New for 2019?

With Winter setting in and the Turkey Shoot over, it is just about time to begin making plans for the 2019 cruising season. In this article Barry Hayes of UK Sailmakers Ireland provides some tips and options to make your cruising faster, safer, and more enjoyable experience – without breaking the bank.

Making sailing easy

Properly-shaped sails make cruising easy, since your boat will heel less when the breeze is up. Less heeling makes sailing more enjoyable and more relaxing for the less experienced crew members. One way to reduce heeling is to set your sails correctly for the weather you have. Tucking a reef in before the weather comes in helps build crew confidence and experience. No one cares when you will get where you're going as long as you get there comfortable.

Gennakers with Stashers

Cruising with a gennaker is often viewed as a complicated affair, especially when sailing shorthanded. However, adding a stasher to your current gennaker is an easy option – and they are simple to use! They take the complication out of flying your spinnaker while shorthanded.

A stasher is, in essence, a “sock” containing your spinnaker. After hoisting the sail in the sock simply pull the stasher to the top of the mast using the pulley system and tie it off. To douse the spinnaker simply ease the sheet and pull the stasher back down, dousing the spinnaker inside the sock. Stashers are light, reliable, simple to use even when single-handed, and can be retrofitted to any spinnaker – stashers are an inexpensive way of getting more use out of your cruising gennaker.

Note it is best to have a stasher without a hard fibreglass end – these are heavy and may scratch the inside of the boat - a soft neck stasher is best.

A stasher is also an excellent add-on for club racing using the lightweight version. It makes getting around the cans that much easier. Read more in the UK Sailmakers' Tips to Setting Up & Handing the Cruising Spinnaker in the pdf downloadable below.

Furling Gennakers

A furling gennaker is a considerable upgrade over a stasher. Furling gennakers have evolved considerably over the past half decade – there are now furling gennakers with a cable in the luff of the sail, allowing the sail to furl like a furling genoa.

See the photos below as an example.

The Code D easy furl gennaker is the latest evolution in cruising gennaker design. The sail is quick and simple to furl, straight from the cockpit, and can be left hoisted until safely docked. Having this sail as a ‘top down’ furling option is even better - top down furling produces a tighter furl with no risk of unplanned openings – life couldn’t be easier.

Stashers and Furling Gennakers have completely transformed cruising for many sailors. Long gone are the days of dropping your gennaker in the water and fighting to recover them. Stashes and Furlers make launch and recovery safe, quick, and simple.

In Mast Furling Mainsail - Battens

Furling mainsails with battens can be a curse if not handled correctly. Sails with full-length battens can often jam inside the mast. It is easy to shorten these battens to prevent them jamming. Having firm halyard tension keep the luff and sail in shape when furling. It also helps to keep a little tension on the outhaul to ensure a compact furl. most new in-mast furling mainsails come with a Thimble in the clew. As they are friction free and never brake. They are also a lot lighter.

Lazy Cradles

A good lazy cradle is absolutely invaluable for cruising - they are the best thing on the market. Now that winter is settling in it is a great time to ensure there are small reinforced holes to allow your cover to drain properly, and to add straps so the bag can be rolled away and stowed on the boom when sailing. (Link) the lazy cradle is an excellent way to make sailing easy. While having the roll away option keeps a clean aerodynamic flow over your mainsail,

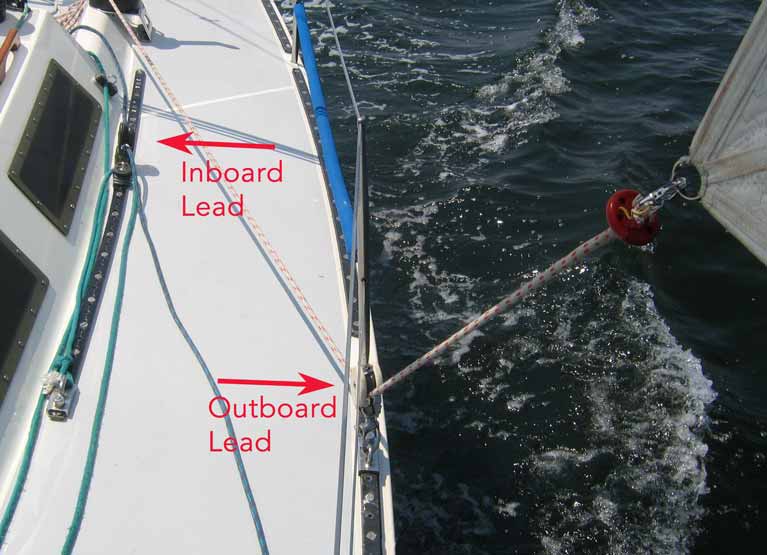

Genoa – Outboard Lead

When broad reaching with your genoa it is best to move the car forward to ensure the sail does not over twist – even better is to set the sail on an outboard lead. This will result in a notable increase in boat speed while also unloading the helm – making the boat much easier to keep on course.

To determine where to place the outboard lead pad eye simply imagine a line from the middle of the genoa luff through the clew (when the sail is eased for broad reaching) and on to the deck – this is the point where the outboard lead needs to be set from. If in doubt – set it a little further forward. This keeps the sheet load on the leech and creates a twist profile to match an eased mainsail.

Wing on Wing Sailing

This is fun and easy way to cruise with the wind behind you. For boats with non-overlapping headsails sailing wing-on-wing can be done without a whisker pole. Just move to attach a block to the rail forward of the shrouds and run the sheet through it.

This will hold the clew of the jib outside the lifelines and give you enough leech tension to keep the top of the sail flying Having the clew “locked” outside the lifelines also makes it safer for your crew to move around the deck without the clew flop across and hitting them. On boats with overlapping genoas, you can not sail wing-on-wing without setting a whisker pole.

To protect your crew from the boom gybing accidentally, rig a preventer to the boom that will hold it out and protect you from a flying gybe. To make setting a preventer easier, make sure to have it rigged all the time. The best set up is to have a piece of line attached to the end of the boom that is long enough to reach the boom vang bail on the boom. This line should end with an eye-splice. When not in use, the preventer runs along the bottom of the boom and tied off to the boom vang bail. When you want to set it, shackle a line to the eye splice that is long enough to go to a block on the rail just aft of the bow pulpit and then runs aft to a winch.

UV Strips & Maintenance

The biggest killer of sails is UV ray damage. It breaks down the fibres or materials used in your sails making them fragile and easy to tear. Having a well-maintained UV strip on the leech and foot of your roller furling genoa is essential to ensure a long lasting sail.

Over time the stitching on the UV strip breaks down, as does the canvas fabric itself. UV strips are sacrificial. There is no stopping UV rays – it is best the replaceable canvas UV strip takes the brunt of the damage rather than your precious sail!

It is also important to check common wear points such as spreader patches, stanchion patches, and where the sail contact the radar dome/deck light if fitted.

Leech Line Cleats

Ensure your main and genoa have good leech line cleats. As the old saying goes – “a flappy sail is not a happy sail” – leech flutter breaks down sail fabric over time. It is very easy to avoid by having your leech lines correctly tensioned.

Winter Service

Annual servicing of your sails is essential to getting off on the right foot for the coming season. Checking over, drying, and correctly storing your sails will go a long way to ensuring you are ready to go sailing on the first nice day of spring.

Please be careful when using cleaning agents on the sail. As they may burn the sail fabric. Only use recommended cleaning products. Always add your spreader and station patches on the sail so they protect the base layer fabric.