Displaying items by tag: UK Sailmakers Ireland

Headsails - Overlapping or Non-Overlapping: Which is Best?

Olympic keelboat helmsman Mark Mansfield of UK Sailmakers Ireland discusses headsail options

If you go back 20 years, or even 15, most designs coming out had large overlapping (headsail goes outside the shrouds) headsails to give them power in the light airs. Many of these designs were fairly heavy and needed the extra sail. However some were built lightly and even though designed with Overlapping headsails, are able to convert very successfully to non-overlapping (headsail is forward of the shrouds and spreaders).

It was the likes of designers John Corby, Jason Ker and Mark Mills who highlighted in their designs that non overlapping was all that was needed, even in light airs, as long as the boats were not too heavy and the masts were placed well back in the boat to allow a generous foredeck size, which in turn allowed a fairly large Headsail to be set forward of the spreaders.

What designs work well as non-overlapping?

There are a number of factors to be taken into account when looking at a boat to see if non-overlapping is worth doing. Here are some—

- Does the Sail area/Displacement ratio show that this design can work well in light airs with a non-overlapper?

- Was the boat designed first day with a fairly large foretriangle—with the mast well aft?

- Does the design have a low wetted surface area, as in light airs, a low wetted surface area helps to survive with a smaller headsail?

What designs do we know of that can be converted?

Likely the most successful design that is able to be adapted, without any work, from Overlapping to non-overlapping Headsails, is the J109. These boats were designed originally in the US for lightish air conditions and had big 135% headsails. However, they were also built quite light (about 5000Kgs) and had quite a large foredeck (j-- about 4 metres). As IRC penalizes sail heavily, it was found about 12 years ago that to just change from a 42 sq metre headsail to a 31 sq metre, non-overlapping headsail saved about 15 points in rating. It was also found that in only under about 9 knots of wind would the smaller sail boat be slower. As a result, most J109’s now rated on IRC, are with the smaller headsails.

J109 Something else, owned by John and Brian Hall, with non-overlapping furling headsail Photo: Afloat

J109 Something else, owned by John and Brian Hall, with non-overlapping furling headsail Photo: Afloat

If you take a similar weight boat, like an Elan 333, it doesn’t work well with them, as their foredeck measurement is only about 3.6 m. In addition, their forestay is not that high, so even with an overlapping headsail, they only have about 32 sq metres of Headsail. If they were to go non-overlapping, they would need to come down to circa 22 sq metres and that would make them very vulnerable in light airs.

What other designs are suitable for conversion?

At UK Sailmakers this year, we have assisted in the conversion on many designs from Overlapping to non-overlapping. Normally this happens when the overlapping headsails get to the end of their life and the option to move to non-overlapping is suggested. The benefits of making the move, if it works for the boat, are:

- Less expensive headsails

- Easier and faster to crew—Less sail to winch in after every tack. Easier to Hoist and drop.

- more competitive on IRC.

- The Boat normally points higher as the smaller headsail is set further inboard.

- Boat is more manoeuvrable with the smaller sail

Designs we have done this year are:

- X362 sport—Similar weight and sail area as a J109

- Beneteau 44.7. We converted both Lively Lady and White Tiger this year to non-overlapping.

- Starflash Quarter tonner—Superhero—Won Icras class 4 this year

- Formula 28

- Beneteau 34.7

Leslie Parnell's, Beneteau 34.7, with UK Sailmakers non-overlapping furling Uni Titanium headsail and mainsail Photo: UK Sailmakers Ireland

Leslie Parnell's, Beneteau 34.7, with UK Sailmakers non-overlapping furling Uni Titanium headsail and mainsail Photo: UK Sailmakers Ireland

In the case of the two Beneteau 44.7’s this decision was made easier by seeing how a similar design had done in the Solent a few years ago, including winning the RORC overall points championship. When we look at a possible conversion boat, we see how similar conversions may have worked on similar designs, before making the decision with the client.

The Beneteau 44.7’s and Beneteau 34.7 all use Roller headsails, so conversion can happen both with Roller headsails boats as well as boats with Headfoils

The Dublin Bay Beneteau 44.7 Lively Lady with UK Sails Photo: UK Sailmakers Ireland

The Dublin Bay Beneteau 44.7 Lively Lady with UK Sails Photo: UK Sailmakers Ireland

Large builders like J boats, X yachts, Beneteau and others have been building lightish displacement cruiser racers for quite a few years. Their older designs are very often suitable for conversion. Their newer designs already are all non-overlapping.

Quarter tonners and Half tonners benefit from conversion, but only when their masts and keels have been moved aft to allow a larger non-overlapping headsail to be set. This can be an expensive operation. In larger cruiser racers this is rarely an alternative.

In nearly all cases when a boat converts from overlapping to non-overlapping, an inhauler needs to be fitted to pull the headsail clew further inboard. This allows the new non-overlapping headsails to be designed with fullness in the sail, and also allows the sail to be flattened easily. Normally the new non-overlapping headsail would be designed to go from 0 to about 16/18 Knots. Then the boats existing no 3 can be used. In some cases, owners will ask for two headsails to fill this 0-17 knot range and a full light air sail (J1) will bring the boat up to 10/11 knots, then a J2 will be used from about 12 to 17 knots.

Maybe this is twice the cost, but bear in mind that the two sails will likely have only half the use, and so will last twice as long.

Do you need to change to non-overlapping?

As discussed above, some designs just don’t work as a non-overlapper. If you have a design that would work as a non-overlapper, you can still opt to sail, at a higher rating, with the big overlapping sail. I recently competed in the J109 UK Nationals in Medium to strong winds. In the J109 class over there, they allow both non-overlapping setups, and overlapping setups to be used, with no difference in rating. It's just first across the line. Problem is, if you choose the big sails, you must stay with them for the whole regatta. Likewise, if you choose the smaller non-overlapping sails, you must stay with them.

In our case, we only had the Overlapping headsails and in a medium to strong wind regatta, we had to carry the big overlapping headsails right up to 20 knots. What we learned from this, is if you have the Rig correct, you can still compete very well, even in conditions that were regarded as too much wind for the sails. The trick is to try and keep the forestay straight by tightening the Lowers and intermediate shrouds a lot. This allows you to apply extra backstay to keep the headstay tight. In conditions that should have suited the Non Overlapping boats, we ended up winning the Nationals by 10 points. Lesson learned was that non-overlapping isn’t always necessary, but bear in mind this was not under IRC. If it was, it might have been a different story.

J109 Jukebox coming off the line at Uk J109 nationals—Notice large overlapping headsail. Photo: UK Sailmakers Ireland

J109 Jukebox coming off the line at Uk J109 nationals—Notice large overlapping headsail. Photo: UK Sailmakers Ireland

Can a boat be assessed to see if it is suitable for conversion?

At UK Sailmakers Ireland, we have a number of very experienced sailors and Sail designers that can look at individual designs and give a very good opinion on whether it is worth doing or not. If an owner wanted, we also have the services of an expert Naval Architect Consultant who can assist, on a fee basis, and do an individual report on a boat.

So, whether you are racing at the top end of ICRAs or sailing for fun in club racing, it is always best to get the advice of your sailmaker and UK sailmakers Ireland have been around helping clients for 50 years. Give us a call or an email if you want any help or advice (contact details below)

Continued Offshore Successes for UK Sailmakers Ireland

Barry Hayes, Director of UK Sailmakers Ireland highlights some recent successes for Boats flying UK Sailmakers sails from Ireland, both around the country and in the Solent

Following on from considerable inshore successes for UK Sailmakers Ireland (three IRC class winners at ICRAs, four IRC class winners at the Sovereign's Cup in Kinsale) UK Sails are thrilled with the results being achieved in the uber-competitive offshore and coastal racing around Ireland and elsewhere.

Last weekend, Jackknife, the J125 owned by Andrew Hall from Pwllheli Sailing Club, was the overall winner of the Dun Laoghaire to Pwllheli ISORA race and now holds a 34-point lead in the overall season's ISORA standings from Paul O'Higgins' JPK 10.80 from the Royal Irish Yacht Club. Jackknife has a full UK Sails Inventory, including specialist offshore sails such as a flying Jib and a Code 0.

UK Sailmakers Code 0 on J125 Jackknife

UK Sailmakers Code 0 on J125 Jackknife

Rockabill, the overall 2019 Dun Laoghaire to Dingle Race winner also carries UK Sailmakers Spinnakers and a Code 0 A sail.

Paul O'Higgins' Rockabill VI, running square with her UK Sailmaker's S2 running spinnaker

Paul O'Higgins' Rockabill VI, running square with her UK Sailmaker's S2 running spinnaker

Over in the Solent, the newly built one-off 36-footer, Erik van Vuuren's Dutch W36 Hubo, was the Class Three winner of the RORC Channel race. This boat, built only one year ago, has a full suit of sails from UK Sailmakers Ireland, designed and fitted by Barry Hayes. She carries, along with her Uni Titanium headsails and mainsail, offshore specialist sails such as a Code A0 and a staysail.

Hubo with her S2 spinnaker, staysail and Uni Titanium mainsail

Hubo with her S2 spinnaker, staysail and Uni Titanium mainsail

Other recent coastal and offshore successes include George Sisk's XP 44 Wow (RIYC), counting all first places, winning the Offshore Division at the Sovereign's Cup. Wow, among her full UK Sailmakers inventory, utilised her flying Jib and Code 0 to great success in that event.

George Sisk's Wow, With her Flying Jib off a sprit and her headsail off her forestay

George Sisk's Wow, With her Flying Jib off a sprit and her headsail off her forestay

At Dun Laoghaire Regatta, Seamus Fitzpatrick’s elegant First 50 Mermaid IV (RIYC), sporting new UK sailmakers Titanium Mainsail and furling Headsail, counted all wins to take the coastal division crown from a strong 30 boat fleet. Wow finished third also in this class. Seven of the top 13 boats in this class used UK sails.

Mermaid IV, sporting her new UK Sailmakers Titanium Main and Furling Headsail. Wow is in the background on port tack

Mermaid IV, sporting her new UK Sailmakers Titanium Main and Furling Headsail. Wow is in the background on port tack

UK Sailmakers offer a bespoke, hands-on service to their clients and will, and can, assist in all aspects of boat preparation and setups from IRC optimisations, rig tuning, sail selections. Our top race teams include Barry Hayes and Graham Curran, UK Sailmakers Directors and Olympian, Mark Mansfield, who is a UK sailmakers agent. Recent additions to the UK team include agents Yannick Lemonnier from Galway, a very well known offshore sailor. Also added to the UK Sailmakers team is agent, Andrew Steenson from Strangford Lough.

Contact us now to discuss your proposals for 2020 sails.

A Lesson in the Need for Twist in Sails

"Twist" is one of the many buzzwords in sailing. We might know what it is and when it's needed – and when it’s not – but why do we need twist in the first place? And what effects does it have in our decision making process all around the race course? Graham Curran of UK Sailmakers Ireland takes us through his thoughts on sail twist.

Walking through Dublin Airport arrivals, fresh off the plane from Southampton after the weekends’ RORC Channel Race, I was going through the events of the previous day and night. I was sailing aboard Chris Frost’s Swan 36 “Finola” in preparation for our Fastnet Race starting next weekend.

We crossed the line at 0800 on Sunday morning after 23 hours of racing – finishing 2nd in our class about four minutes behind the winner. As is usually the chase when you finish second; I was going through the race in my head to find where we could have gained those four minutes of corrected time. There were several occasions where there were gains to be had or losses that could have been avoided, but there is one in particular which we found interesting – and which leads into the topic of this article.

Critical Sail Selection

At 0200 on Sunday morning we were in the last 40 mile stretch of our course – approaching the Owers turning mark before heading back for the Solent. We had been flying our S2 spinnaker (symmetric runner) since the start of this long downwind leg in 12-15 knots of breeze. As we rounded St Catherine’s point and made our way to Owers the breeze began to steadily clock right; making our sailing angle tighter and tighter.

Eventually, we ended up tight reaching with our pole just off the forestay with our log reading around 6.8 – 7.5 knots with a significant load on the helm and lots of active mainsheet trimming needed to keep the boat on her feet. Something needed to change. Finola’s set up left us with three options – continue as we were, unfurl our 145% overlapping genoa and set up on an outboard lead, or swap to our Code Zero. There were several things to consider when making this decision including the late hour, the breeze, sail sizes, effective ranges etc.

"Something needed to change"

Our decision was to drop the spinnaker and unfurl our genoa and set up an outboard lead for effective sheeting, and then consider launching our Code Zero after evaluating the situation. As always the lads on the bow played a blinder; the drop and swap was done seamlessly without issue. We gave ourselves ten minutes to settle and evaluate and found the boat was much easier to handle with little or no undue pressure on the helm, but our speed was down to 6.0 knots – time to try the Code Zero. After a short period of bow work and cockpit setup we had the Code Zero flying and our genoa furled up once again. Settle and evaluate. Finola was now cruising along at 6.8 to 7.5 knots once again, as we were with our S2 spinnaker up, but the difference in her behaviour was dramatic. No significant heel and a wonderfully balanced helm. A valuable lesson learned (several lessons in fact) – but what does all this have to do with twist you ask? Let me explain.

What is Twist?

Twist in its raw form is a difference in your sails’ angle of incidence when measured at points of increasing height up your sail. Simply put; it is the amount the sail “twists open” at the top when compared to the lower sections.

"We increase twist in light winds, we take it out as the wind increases"

Most of us think of twist in the context of sailing upwind with a mainsail and jib/genoa. We increase twist in light winds, we take it out as the wind increases. This has a lot to do with how the wind is behaving at different heights. Wind that is closer to the surface is slowed due to friction and, as a result, its angle is changed. Wind which is higher (farther from the surface) does not experience the same amount of friction, so its angle is not changed as much. As such we have varying wind angles at increasing heights so we, in turn, need to twist our sails to make sure our sail is trimmed correctly to the changing wind angles at the different heights. This is particularly important at low wind speeds where the wind angle difference is significant. As the wind speed increases the surface friction has less of an effect on the wind angle – there ends up being little difference in angle between the top and bottom of your mast (depending on your mast height of course) – so less twist is needed to trim your sail correctly.

The above applies to sailing upwind – and we are familiar with it as a sail trim fundamental – but there is another more intrinsic way of looking at twist which applies to all modes of sailing. In essence twist gives us the ability to control the lift and drag produced by our sails.

W36 “Hubo” on her way out of the Solent. Hubo went on to win the IRC Two-Handed Division and IRC Class 3 overall Photo: RORC/Rick Tomlinson

W36 “Hubo” on her way out of the Solent. Hubo went on to win the IRC Two-Handed Division and IRC Class 3 overall Photo: RORC/Rick Tomlinson

The Lift and Drag Compromise

Life is all about compromise. Sailing is no different. Where there is lift, there is drag. Our goal as sailors is to maximise and harness lift while minimizing resulting drag. Lift gives us the power to move forward, above and below the water. Drag is what slows us down, usually manifesting itself as heel and stall.

So lift and drag are intrinsically linked – they go hand in hand. In some cases drag is a good thing. There is a tipping point where having a relatively high amount of drag is good as its corresponding lift is more beneficial to the entire sail plan. But for the vast majority of our sailing drag is bad, lift is good.

So how does this tie in with Sunday morning’s lesson aboard Finola?

Drag Bad, Lift Good

Let’s keep it simple, primal as it were – down to caveman style “drag bad … lift good”. When we were reaching with our S2 spinnaker we had plenty of lift. The boat was moving through the water at hull speed or above it. We had all the lift we needed. The problem was that the spinnaker was causing too much drag, which manifested itself as heeling moment. To keep the boat on her toes we need to use a lot of rudder and ease the mainsheet. More rudder means more drag below the waterline – slowing the boat as a result. All of this making the crew work much harder than is needed at 2am in the morning.

This is not the spinnaker’s fault. A running spinnaker will simply, by design, not reach effectively. It has a deep profile with wide shoulders. Great for running downwind. Not so great when sheeted in hard while reaching. The shoulders close in behind the mainsail, hook, and stall, causing drag and heeling the boat.

So we opt for the genoa instead of instead – dramatically less drag as the sail can be trimmed perfectly for the angle of sailing with the ability to get the twist correct without causing any hook (drag) in the leech – but the sail did not produce enough lift to keep us at the speeds we were doing with the spinnaker. This is mainly due to the drop in sail area, the genoa; even at 145% overlap, is less than half the size of the spinnaker. So on the whole it was more effective having the spinnaker up, despite its drag downsides.

Enter the Code Zero. At 58sqm it splits the difference in size between the spinnaker and genoa but, far more crucially, it is designed with much more twist in the leech. When we trimmed our Code Zero on the log instantly jumped back to the 7ish knots we were looking for – but without the excessive heel we had with the spinnaker. A Code Zero is designed to sail with a lot more twist in its leech when compares to a running spinnaker. Although the Code Zero will produce less lift, mostly because it has a smaller sail area, it will also produce less drag than a hooked stalling spinnaker. The Code Zero produces more net lift, despite its smaller size, and it all comes down to what? – twist.

Code Zeros set at the start of the RORC Channel Race 2019 Photo: RORC/Rick Tomlinson

Code Zeros set at the start of the RORC Channel Race 2019 Photo: RORC/Rick Tomlinson

Conclusion(s) about twist

To be very clear, this is not a pump piece for Code Zeros. They are great sails and they have their place, and are much more versatile than they are given credit for, but that is not the point here.

We used twist to reduce drag and increase lift. We did it in the form of a sail change. But this is not always the case. Next time you’re sailing and you’re fighting the helm, or your boat speed is slow and you don’t know why, or you need to accelerate to avoid being rolled – consider the lift and drag relationship and use twist to tip the balance in your favour.

Before I sign off I want to share two more quick notes on this particular situation.

Firstly – we used the Channel Race explicitly for the purposes of learning ahead of the Fastnet. I would certainly consider not swapping to the Code Zero straight away as a mistake in the context of the Channel Race alone. It may not have cost us the four minutes needed to win but it certainly contributed. But in reality – that is exactly what we were there to do – that was the time to be conservative and learn the lesson. The minute or so of lost time during the 2019 Channel Race could potentially yield many more minutes of time gained in next week’s Fastnet Race as we now has a very clear understanding of where and when the Code Zero becomes effective in our inventory. These lessons need to be learned some time – best to do it before the big one rather than during it! As always – time on the water is key!

Secondly and finally – a note on sail area. It is not the be-all and end-all, as we’ve just proven. Bigger is not always better. Design and effective application are far more important. So next time you think “throw up the biggest one we have!” stop and consider the situation – you may just find the net gain elsewhere.

Spinnakers: Normal Symmetric Style or Asymmetric?

Barry Hayes of UK Sailmakers Ireland goes through the options for racing boats to go Symmetrical or Asymmetrical with their spinnakers. Barry sailed aboard George Sisk's XP44 WOW from Royal Irish Yacht Club at this year's Sovereigns Cup, where WOW won all races in the Coastal Division. UK Sailmaker's boats also won Class One, Whitesail One and the 1720 Sportsboat divisions at the Cup.

In the past 10 or 15 years, spinnaker options have increased considerably. Prior to that, it was fairly straightforward. You bought a light air symmetric spinnaker, a heavy air version of the same and maybe a reaching spinnaker.

In recent years, however, Asymmetric spinnakers have become a lot more efficient and some yacht builders, particularly J boats, feature them almost exclusively on their models. Below we are going to do an analysis of which option is better for racing inshore/offshore.

First the pros and cons of each option:

Asymmetric Spinnakers

Pros

- Easier trimmed and handled

- IRC rating allows larger asymmetric spinnakers for the same rating, relative to symmetrics

- Very efficient when reaching as shape allows better exhaust of the air.

- Code 0 models (very flat Asymmetric) is a must for offshore boats

Cons

- Needs a sprit or prodder to set them properly away from the bow.

- They don’t run as deep and efficiently as Symmetric spinnakers.

- In Heavy air, they sometimes can wrap around the forestay when gybing

- Time is always lost gybing, compared to boats with poles

George Sisk's XP 44 WOW from the Royal Irish, with her Matrix A2 Asymmetrical spinnaker and Uni Titanium main Photo: Bob Bateman

George Sisk's XP 44 WOW from the Royal Irish, with her Matrix A2 Asymmetrical spinnaker and Uni Titanium main Photo: Bob Bateman

Symmetric Spinnakers

Pros

- Once above 12 knots, they are very efficient running with pole pulled back.

- Tactically, they offer a better crew, greater options downwind.

- Very little time lost while gybing.

Cons

- Expensive on IRC rating—On a J109 it costs about 7 points if you want the same sized spinnaker

- Not as efficient when reaching due to shape

- much more difficult to hoist and trim properly

The J109 Outrageous - the spinnaker pole is fully back in 18 knots Photo: Bob Bateman

The J109 Outrageous - the spinnaker pole is fully back in 18 knots Photo: Bob Bateman

At UK Sailmakers Ireland, we had a J109 client this year that opted to go for Symmetric spinnakers on a boat that is designed for A sails. Before we went down this route, we did extensive testing and trial certs to see what the benefits would be. The bottom line is that there is no perfect answer. Were you able to have two IRC certs (one Symmetric, one Asymmetric), and be able to select which one, each race, then you would have both set-ups.

However IRC does not allow this and most regattas insist you don’t change your cert in the last 10 days before a regatta, as long-range weather forecast details may play a part in your decision.

A number of other sprit boats have moved to Symmetric this year, including Anthony O'Leary’s converted 1720, Antix Beag from Royal Cork and Stephen Quinn’s J97 Lambay Rules from Howth.

Andrew Hall's Jackknife, winning in ISORA with his UK Sails Matrix A4 Asymmetric spinnakers and Uni Titanium Main

Andrew Hall's Jackknife, winning in ISORA with his UK Sails Matrix A4 Asymmetric spinnakers and Uni Titanium Main

Bottom Line —A sails are generally more efficient on normal cruisers in less than 12 knots than symmetric spinnakers. Why?

Up to 12 knots, most symmetric boats struggle to get their spinnaker poles back that far, as the spinnaker will collapse. So an A2 Asymmetric boat will likely be able to run as deep as an S2 Symmetric boat, but the A2 Asymmetric usually will have a larger spinnaker area and a lower rating. IRC, it appears, penalises a boat with a pole by about seven points (on a J109), for the ability to be able to pull the pole back and go deep.

In light airs, if you can’t get the pole back, then you are at a disadvantage. Add to that, an Asymmetric sail is more efficient going at higher angles, than boats with symmetric spinnaker.

Bottom Line—Symmetric spinnakers are more efficient running in more than 14 knots. Why?

Once a symmetric boat can get its pole fully back, it can normally nearly run square, or maybe 10 degrees off square. A similar designed boat with an Asymmetric spinnaker will likely go the same speed, but be 10 degrees or more higher. When the two boats get to the bottom mark, the Symmetric boat has likely pulled out 30 to 60 seconds. Add to this, the symmetric boat can throw in gybes easily to stay in wind or get away from other boats' wind shadows, and the gain becomes even larger. If the wind gets up to 20 knots or more running, the symmetric boats have an even bigger advantage.

Paul O'Higgins's JPK 10.80 Rockabill VI from the Royal Irish, winner of this year's Dun Laoghaire to Dingle Race, running square with her UK sails Matrix symmetric spinnaker

Paul O'Higgins's JPK 10.80 Rockabill VI from the Royal Irish, winner of this year's Dun Laoghaire to Dingle Race, running square with her UK sails Matrix symmetric spinnaker

Bottom Line—Asymmetric boats are generally more efficient offshore and on Coastal racing.

This is because the two scenarios above relate to running square downwind, as you would have in Windward Leeward racing. On offshore and coastal races, often there is a lot of reaching and broad reaching. The A sail boats then have their rating advantage, and the efficiency of the A sail when reaching.

George Sisk's XP 44 Wow on the way to winning Sovereigns Cup—Coastal with his Uni Titanium sails

George Sisk's XP 44 Wow on the way to winning Sovereigns Cup—Coastal with his Uni Titanium sails

What are the crewing considerations?

Trimming a symmetric spinnaker is considerably more difficult to do well, than trimming an Asymmetric spinnaker. A symmetric spinnaker needs the sheet adjusted constantly, the guy adjusting the angle of the pole is constantly being adjusted, as is the pole height and the spinnaker tweaker.

On an Asymmetric sail, it is generally just the A sail sheet that is adjusted. You may move the tackline in and out a bit, but not that much. As a result, to get the best out of a symmetrical spinnaker, more good crew are needed to trim it well.

What about boats having both sail setups?

Any boat opting for a symmetric setup should also be planning to take some Asymmetric spinnakers as well. To do this efficiently, it needs a small sprit or prodder, to use with the A-sail for reaching conditions. The IRC rule allows a prodder (or sprit) on a symmetrically configured boat, as long as the prodder does not extend out further than the pole does.

However, the A sail size (SPA) on these A sails cannot be any bigger than the largest symmetric spinnaker. So in the case of our J109 this year which went Symmetric, we opted for a 102 sq. metre Symmetric spinnaker, which is six sq metres smaller than the Class A sail size. This saved us two points off the rating, so the seven-point hit for the pole was lessened to five points overall. The new A sails added, to cover her reaching requirements were a code 0 for light air reaching and an AO, for light air running. The AO can be used off the prodder, or can also be transferred to a lowered pole, with the pole being pulled back to allow further depth.

In these photos you can see the Warship 36 using both the pole (above) and Asym set up (below) with her UK Sails A0 and S2 spinnaker

In these photos you can see the Warship 36 using both the pole (above) and Asym set up (below) with her UK Sails A0 and S2 spinnaker

Cost Considerations

For an existing Symmetrical boat, changing to No pole and just using A sails would require,

- A sprit

- New Spinnaker specific A sail sheets

- New Asymmetrical spinnakers

- A tack line to attach the A sail to the Sprit

For an existing A sail boat, to go to Symmetrical configuration requires,

- A pole

- A track on the mast

- additional Blocks etc. to cover sheets and guys and pole downhaul

- Symmetrical spinnakers and perhaps some A sails as well.

For someone ordering a new boat—Best to try and incorporate both options from day one, even if only opting for one setup.

So –Which option to go for?

As I said in my opening paragraph, there is no perfect choice, but here is a quick plan.

- For Light planing boats - Go A sail, as you will always be going higher angles

- For short-handed - A sail is a lot easier for Handling

- For Offshore/Coastal - A sail will likely be best, as more reaching than running

- For Inshore, in lighter air areas, go A-sail

- For Inshore in stronger wind areas - Go Symmetric.

- For Inshore in mixed conditions -Either works, but Symmetric with a good crew might just have the edge if you also have some good A sail options as well.

UK Sailmakers Ireland Have a highly experienced and Knowledgeable team to assist you in any sail choice or query you may have. Please feel free to contact any of the below to discuss your needs.

The Flying Jib - WOW's 'Secret Weapon'

The XP44 'WOW' stormed home to win the Coastal Class of Sovereigns Cup 2019 this month. The prize giving ensued after which began the bar talk debrief of the week between sailors from all boats writes Graham Curran of UK Sailmakers Ireland.

Some of this chat focused on WOW’s ‘secret weapon’ – her Flying Jib (FJ).

Flying Jibs, although new to Irish waters, have become common sights on offshore and coastal racers worldwide over the last couple of years. An FJ provides speed and stability while filling a tricky gap in the sail inventory between code zero and heavy reaching spinnaker. So what is involved? And what are the tangible benefits?

XP44 “WOW” with her Uni-Titanium Flying Jib deployed. Photo: UK Sailmakers Ireland

XP44 “WOW” with her Uni-Titanium Flying Jib deployed. Photo: UK Sailmakers Ireland

Bow Down; Power On

A common issue with a modern non-overlapping sail plan is an 'unbalance' when broad reaching – sometimes resulting in a broach to windward. This usually occurs when the breeze is up. Imagine broad reaching in 18 knots – you are too tight and pressed to hold your code zero, but not deep enough to set your A5 heavy reacher – so what do you do? Two sail the leg with your jib and main (hopefully with the jib on an outboard lead). At this point the boat is out of balance – the headsail will never produce as much power in front of the rig as the mainsail does behind it – unbalanced.

Enter the Flying Jib

Flown off a bowsprit, to clear the forestay, the flying jib adds additional sail area to the front of the boat, encouraging the bow down. This extra force counteracts the power of the mainsail – thus balancing the boat. More than just sail area, the flying jib also creates a third ‘slot’ in the sail plan. More slots equals more power. More power, when correctly balanced, equals more speed.

This advantage became very apparently off Kinsale last Friday when WOW, trailing her bigger sister FREYA, was able to close the distance and catch the opposition with her flying jib deployed. The flying jib gave WOW an extra 1.5 knots of boat speed.

Ease of Use, Plug and Play

WOW’s flying jib and code zero are both set on anti-torsion cables which plug into her Ubi Maior ratchet furler. Both sails can be ready to hoist in seconds, quickly deployed, and safely recovered with the ratchet action of the furler preventing accidental deployment.

The sail is designed to sheet to the same point as the code zero so no additional sheets or hardware are needed. It is very much a complementary plug and play sail system.

WOW was the only boat in her fleet with a flying jib – she is equipped with a versatile modern performance sail plan for optimum sailing on all points of sail – bring your sail plan into the future with a UK Sailmakers Flying Jib.

Kinsale Delivers: UK Sailmakers Customers’ Capitalise

A busy June period drew to a close this weekend; concluding with the ever-popular biennial Sovereign's Cup Regatta – writes Graham Curran of UK Sailmakers Ireland. The weather did not make life easy for competitors over the four-day regatta but it certainly made for interesting sails. A mix of downwind surfing, a mythical sunny lay day, maritime hide and seek, and topped off with a day of glorious Kinsale weather which keeps us coming back year after year.

We had a busy couple of days in the loft with the hum of sewing machines running into the late hours of Wednesday and Friday evenings repairing torn sails to keep our customers, and all competitors, on the water with a full inventory.

XP44 “WOW” romps to Coastal Class Victory

George Sisk's XP44 Wow. Photo: Robert Bateman

George Sisk's XP44 Wow. Photo: Robert Bateman

George Sisk’s new WOW showed blistering pace throughout the series to claim overall victory with three wins from three races. Coming off the back of a disappointing end to their Dun Laoghaire to Dingle race the team were fired up and ready to attack the week on Wednesday. The long coastal courses allowed George and his long-standing crew to stretch the boat’s legs upwind and down.

She showed blistering pace at times, particularly on a long return reaching leg into Kinsale on Friday afternoon. WOW is equipped with a bowsprit mounted flying jib on an Ubi Maior furler which she used to great effect on this final leg. Crew member Red Power, commenting on that leg, said “The flying jib was the key on the last reach of the second race. With it we sailed higher and faster than with our zero. WOW had the only flying jib in the fleet and it was noticed.”

Outrajeous Seals Class One Victory

The Murphy/Colwell led J109 “Outrajeous” campaign held their nerve to claim victory in IRC Class One on Saturday. After a dramatic end to Friday’s racing, resulting in a DSQ in race five, the team refocused to win the first windward-leeward race of the day and second in the final race of the series to claim overall victory.

Richard Colwell, ICRA Commodore and owner of Outrajeous, commented “It’s a fantastic win for us, and reward for the hard work put into boat prep, teamwork, and sail development of the last six months. This hard work means we have the speed and ability to compete at the top end of a very competitive class. We are delighted with the progression made by a great team in such a short space of time.”

J109 Outrajeous sailing downwind with her UK Sailmakers branded Matrix Spinnaker. Photo: Bob Bateman

J109 Outrajeous sailing downwind with her UK Sailmakers branded Matrix Spinnaker. Photo: Bob Bateman

Mark Mansfield, agent for Uk Sailmakers Ireland and tactician on Outrajeous, added “The Outrageous Project has been coming along very well, and we have been working with John and Richard since last winter, trialling and testing shapes. We were very quick at Sovereigns in a range of conditions with our Uni Titanium Main and headsails and in particular, very close winded. It is great to be able to perform so well against 7 other similar J109 class boats as it shows we have a very good fast product, able to win against the best. Our win in the 1720 class shows we are able to perform at a top level in one design fleets, as well as on IRC.

The Outrajeous team (L to R): Bryan O’Donnell, Richard Colwell, Robert Kerley, David Cotter, John Murphy, Stuart Harris, Neil Spain, Mark Mansfield

The Outrajeous team (L to R): Bryan O’Donnell, Richard Colwell, Robert Kerley, David Cotter, John Murphy, Stuart Harris, Neil Spain, Mark Mansfield

Looking forward to the next challenge, as always, Mark continues “On Outrageous, we will be making some small changes again before Dun Laoghaire week, to tweak the sails even further. We are now seriously giving owners a proper choice when they are making a decision on who to go for when choosing their new sails. When we work with a client, it is very much a hands-on situation and we help with rig set up, crew training, helm coaching as well as working with the trimmers on how to set up the sails, and what rig/mode changes are needed in different conditions.”

The team celebrated a deserved win in style on Saturday night with family and friends sharing in the victory. Outrajeous now shifts focus to the upcoming Volvo Dun Laoghaire Regatta.

Not So “Slack Alice” triumphs in White Sail One

GK34 “Slack Alice” sailing upwind with her Tape Drive Silver Mainsail and No 1 Genoa. Photo: Bob Bateman

GK34 “Slack Alice” sailing upwind with her Tape Drive Silver Mainsail and No 1 Genoa. Photo: Bob Bateman

Shane Statham and Trudy O’Leary’s GK34 “Slack Alice” claimed victory in White Sail IRC One with four wins from four races this week. Slack Alice is well known in the waters of Cork and is no stranger to victory here either. Shane and his crew opted for the white sails class for competitive racing while also being friendly to the flexible crew roster throughout the four-day series.

Rope Dock Atara Strikes Again; Crowned 1720 European Champions

Ross (helm) and Aoife (bow) McDonald’s Rope Dock Atara – 2019 1720 European Champions. Powered by UK Sailmakers Ireland. Photo: Bob Bateman

Ross (helm) and Aoife (bow) McDonald’s Rope Dock Atara – 2019 1720 European Champions. Powered by UK Sailmakers Ireland. Photo: Bob Bateman

Aoife and Ross McDonald’s “Atara” has successfully defended her 1720 European Championship. Incorporated as a three day series within the 2019 Sovereigns Cup the 1720 Europeans produced tight racing throughout the fleet. Atara set the tone early; winning the first race of the series, and only one of the day, on Friday. They continued with another race win on Saturday and three thirds to clinch the European title three points clear.

Hard work Rewards

It is usually this time of year, after the major events of the year that the hard work of our customers – supported by the UK Sailmakers Ireland team – rewards them with the results they strive for. We are very proud of all our customers this week, and we are honoured to be your sailmaker.

UK Sailmakers Ireland Teams Up with Spinlock

UK Sailmakers Ireland has teamed up with Spinlock to bring sail making to the next level in Ireland for our racing customers writes Barry Hayes.

We have two of Spinlocks new Sail Sense trackers on John Murphy’s J109 Outrajeous on the clew of the J1 Uni- Titanium headsail. And on George Sisk’s XP 44 Wow J 2 Uni -Titanium Headsail So we can bring sail development to the next level.

Sail-Sense is a revolutionary new sensor which helps you be smarter about your sail management

Sail-Sense is a revolutionary new sensor which helps you be smarter about your sail management

As UK Sailmakers Ireland is a sail production loft and as we build sails here in Ireland we needed to get the lowdown on what usage our sails get on the water. So we teamed up with Spinlock to get the low down on it.

The tracker system details here brings the sail usage right to my phone in an app so I can refine the development and design of each sail.

The tracker tracks how much UV, tacking, flogging, usage, and mileage is in play so we get an in-depth view on each sail and how much its use is getting on an app on our phones.

This data will go directly back into the designs of our Uni- Titanium Racing sails. So we can build the sails even better for you.

UK Sailmakers Ireland has had a very successful 2018/2019 season thus far explains Graham Curran – “We’ve had great success over the past year. Success in the sailmaking industry is measured not by sales figures alone but also by the happiness and performance of your customers, and also the ‘vibe’ of the entire sailing community as a whole. If we’re doing well then it indicates a healthiness within the cruiser racer fleets in Ireland – we’re not saying it’s thriving, but it is certainly improved when compared to this time five years ago.”

It’s not possible to be everywhere at once, and with so much sailing happening across the country it is important that we provide a full professional service to all our customers and sailors. To match this renewed demand we are delighted to welcome two more members to our team – Yannick Lemonnier based in Galway – and Andrew Steenson based in Northern Ireland.

“The addition of Yannick and Andrew to the team is a big step for us” says UK's Barry Hayes “It not only gives us a truly countrywide presence but it adds further depth and experience to an already formidable knowledge base. With Graham now based in Dublin full time, Mark Mansfield and I between Cork and Dublin, Yannick in Galway, and Andrew up North, we will be able to provide top class service to sailors on all coasts and inland waterways of the country.”

ANDREW STEENSON – STRANGFORD LOUGH & NORTH

Having come from a family with a strong boating heritage it is no surprise that Andrew has been in and around boats since he was a baby. The family has nearly 800 years of sailing experience in and around the waters of Strangford Lough. Andrew’s great grandfather was a sailmaker who made sails for the 18ft punt class, the River class, and the Dragon class. Andrew is well known in the boat yards around Strangford Lough and further afield.

Andrew Steenson

Andrew Steenson

His extensive knowledge and experience within the marine industry have helped him determine what yachtsmen want and provide a service and product which satisfies their needs. “I am looking forward to working with all the team at UK Sailmakers Ireland to provide the same great products and services they are renowned for down south to sailors in Northern Ireland.”

Andrew can be contacted at: [email protected]

YANNICK LEMONNIER – GALWAY & WEST

Yannick is well known within sailing circles in Ireland having worked as a sailmaker here since 2011. Hailing from an Island near La Rochelle in France sailing was always going to be in his blood. Yannick’s sailing experience speaks for itself; with over 80,000 miles, mostly single or double handed, 5 Solitaire du Figaro, 2 Transatlantic Double Handed, Round Ireland and Fastnet Double handed to name but a few.

Yannick Lemonnier

Yannick Lemonnier

Yannick’s sailing and sailmaking experience make him an excellent fit for our team. He has the attention to detail required to deliver top class sails to customers and the practical knowledge to advise the best solution for the task at hand.

“I am honoured to be welcomed within UK Sailmakers Ireland team having a good knowledge of their products over years servicing sails with West Sails. I will be bringing mainly offshore expertise gained from many Figaro races, Tour Voile, Round Ireland race, Fastnet and many others. I'm looking forward providing new sails and service for mainly the West coast”

Yannick can be contacted at: [email protected]

BUILDING FOR THE FUTURE

Having a countrywide presence is essential for us to provide a service which we demand from ourselves. We continually strive to provide top class service and products to all our customers. We welcome Andrew and Yannick to our team and we look forward to working with all our customers, both old and new, in the coming months of the summer sailing season.

Ireland's Newest XC45 Yacht is on the Way

There is a brand new XC45 yacht on its way to Kinsale, Co Cork writes Barry Hayes of UK Sailmakers Ireland.

Currently lying in the X-Yachts factory yard in Denmark; it will soon be on its way to Irish waters once her sea trials are complete.

UK Sailmakers Ireland specified and designed the sails, they were built in our Hong Kong-based production facility and fitted in the X-Yachts yard by our colleagues as part of our total customer service.

Any new X-Yacht can avail of UK Sailmakers Ireland installation service.

The mainsail and headsail are X-Drive Endure Double Taffeta for ultimate performance cruising and blue water sailing longevity.

The mast on this new yacht is fitted with a 26 mm Harken Switch stack system from UK Sailmakers Ireland. This keeps the mainsail stack low and within easy reach, with the added benefit of less windage with the V boom.

The mast on this new yacht is fitted with a 26 mm Harken Switch stack system from UK Sailmakers Ireland. This keeps the mainsail stack low and within easy reach, with the added benefit of less windage with the V boom.

The mainsail is fully battened with a single line reefing system. The Headsail is fitted with vertical battens and integral reefs for ease of use and versatility.

She also sports a top-down furling code zero which has a UV strip on the leech of the sail so it can be left hoisted for extended periods while cruising. This code zero has an Ubi Maior ratchet furler so the sail is fully secure and can be left hoisted for days on end without the worry of unfurling.

The boat will also be equipped with a Code D asymmetric furling Gennaker which has plug-and-play functionality with the Ub Maior furling system

The boat will also be equipped with a Code D asymmetric furling Gennaker which has plug-and-play functionality with the Ub Maior furling system

The boat will also be equipped with a Code D asymmetric furling Gennaker which has plug-and-play functionality with the Ub Maior furling system.

The boat will arrive in Ireland in two weeks after its sea trials are finished.

We are very proud to support our X-Yachts customers with a worldwide local service.

UK Sailmakers: Titanium Construction

Towards the end of the winter period and during the beginning of spring UK Sailmakers Ireland were out and about doing our rounds of the country’s yacht clubs getting sailors hungry and prepared for the busy season ahead. Our EDU talk this year was based around top tips for fast sailing – always popular for sailors of all levels, and tends to bring out the questions! This year we also had a short segment on component-based sailmaking and sail materials – this was after answering many interesting questions from sailors on the subject during the 2018 sailing season.

Being conscious of avoiding a sales pitch we focused on the core materials and components used in modern sailmaking – carbon, technora, aramids, polyester, dyneema etc – and how these components were able to slot in and out of our particular production processes.

This segment was successful beyond our expectations. Being able to see components in their raw forms, discuss the different manufacturing processes and how each component can slot in and out as needed, and then having finished sail and material samples to touch and feel, it became a very interactive and informative segment for the audience.

We were surprised by some misconceptions surrounding modern formed sails, and even more so by how many sailors knew very little about what actually lay “under the hood” of their sails, both old and new. Having answered many questions and deconstructed many processes and products we felt it was worth satisfying the inner sailing-geek of the other sailors throughout the country.

You would be hard pressed to go racing at a major event in Ireland without seeing a black sail so that seems like a good place to start.

UNI-TITANIUM – GRAND PRIX PERFORMANCE

Titanium is UK Sailmakers’ performance sailing product line in which Uni-Titanium is the top level Grand Prix performance product. There are differences between the of our Titanium products – this is where the “component” based aspect of our production processes becomes crucial – the manufacturing process remains constant but the components being used in each individual sail can alter to suit its specification. This provides us with the freedom to explore, test, and evaluate new components and combinations without altering our manufacturing process. It also allows us to continually monitor our process performance and improve its efficiency.

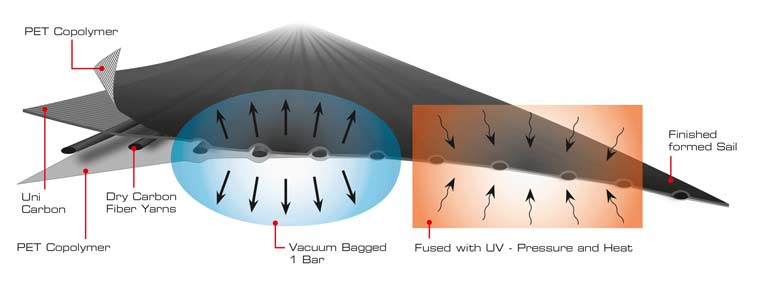

So what is “under the hood” of a Uni-Titanium sail? Watch our video below and find our step by step breakdown below to find out.

THE FORM

Uni-Titanium, like all Titanum sails, are one-piece sails when they leave production. The first step in the process is to manipulate the form into the concave flying shape of the sail

BOTTOM SKIN

The bottom skin is now laid onto the formed form. This skin consists of robotically cut panels which precisely match the form shaping. The outer side of the skin can be one of several different finishes depending on the sail specification. The inner side of the skin is coated with a co-polymer adhesive.

PRIMARY LOADING

Computer simulation is used to calculate the loading a sail will experience once flying in reality. These simulations are not run for every single sail. They are run for many different sizes, aspect ratios, specific design wind ranges etc. From these simulations come yarn layouts. For performance racing projects these simulations are run repeatedly for each sail until the most effective layout is found.

Once a layout for the sail has been chosen; carbon fibre yarns (or whatever component mix is chosen) are laid along the layout paths. These run continuously from corner to corner without interruption. The yarns are laid dry, without glue to reduce weight, and under a constant tension. They are held in place by the tacky coating on the base skin. Because the sail is still in its flying shape on the form the yarns are laid as they will be when the sail is hoisted. These yarns distribute the primary loading of the sail.

SECONDARY AND TERTIARY LOADING

When your sail is hit by a gust it will flex and distort as its power is harnessed, this is essentially a loss of power for the boat. This is realized by having to increase your halyard tension in higher wind speeds.

Unidirectional carbon sheets are laid throughout a Uni-Titanium sail. This is where the “uni” in Uni-Titanium comes from. The purpose of this additional unidirectional carbon is to absorb the secondary and tertiary loading on the sail – harnessing their power instead of it being lost in flex and distortion.

With a Uni-Titanium sail when a gust hits the sail shape does not change unless the trim is altered – it remains in its flying shape without distortion. The means that the full power of the wind is being transferred to your boat; resulting in more drive and lift in your sailplan.

TOP SKIN

The top skin is now laid with the co-polymer side facing down. This completes the sail structure. This top skin can be the same or a different component than the bottom skin. This allows great versatility when specifying the sail construction.

FORMING INTO A ONE PIECE SAIL

Once the sail structure is complete the sail can now move towards the fusing process to turn it into a truly one-piece sail.

A vacuum bag is applied to the form, still in its flying shape, and the sail is vacuum compressed to 1 bar. This squeezes the layers together under immense pressure and causes the co-polymer coatings on each of the skins to infuse through each layer.

The sail is then fused at 125°C with UV heat and pressure. This chemically locks all the layers together – forming them into one single piece.

Once fused the sail is then allowed to cool and cure before moving on for finishing.

PRIMARY AND SECONDARY FINISHING

Once the sail has cured it then moves onto the loft floor for finishing. This is where the detailing of the sail is added. Primary finishing includes patching and reef reinforcements, headboard, clew tack and head attachments, luff tape or hardware installation, batten pockets and tensioning devices, leech and foot lines etc. This is where the sail is transformed from a sail-shaped sheet into a useable sail.

Secondary finishings are also applied in tandem. These include sail numbers, camber stripes, tell tails, class logo, manufacturer logos and other cosmetic details.

ON THE WATER

UK Sailmakers’ Uni-Titanium brings Grand Prix performance to the hands of sailors on racing grounds throughout the country North, South, East and West – look for black sails with the UK Sailmakers logo.