In every industry there are 'nuggets' of information which can completely change how you look at things. Sailmaking is no different. Sometimes these nuggets are so obvious that you kick yourself for not noticing them before but often they only become obvious when an experienced hand points things out. That's according to Graham Curran of UK Sailmakers Ireland who, in the second part of a 'How To...' series in association with ICRA, shares some sailmaking know–how. The only thing the Cork Harbour based sailmaker asks in return is that these nuggets are passed on to other sailors!

Article author Graham Curran, UK Sailmakers Ireland

Article author Graham Curran, UK Sailmakers Ireland

The Mystery of Sail Battens

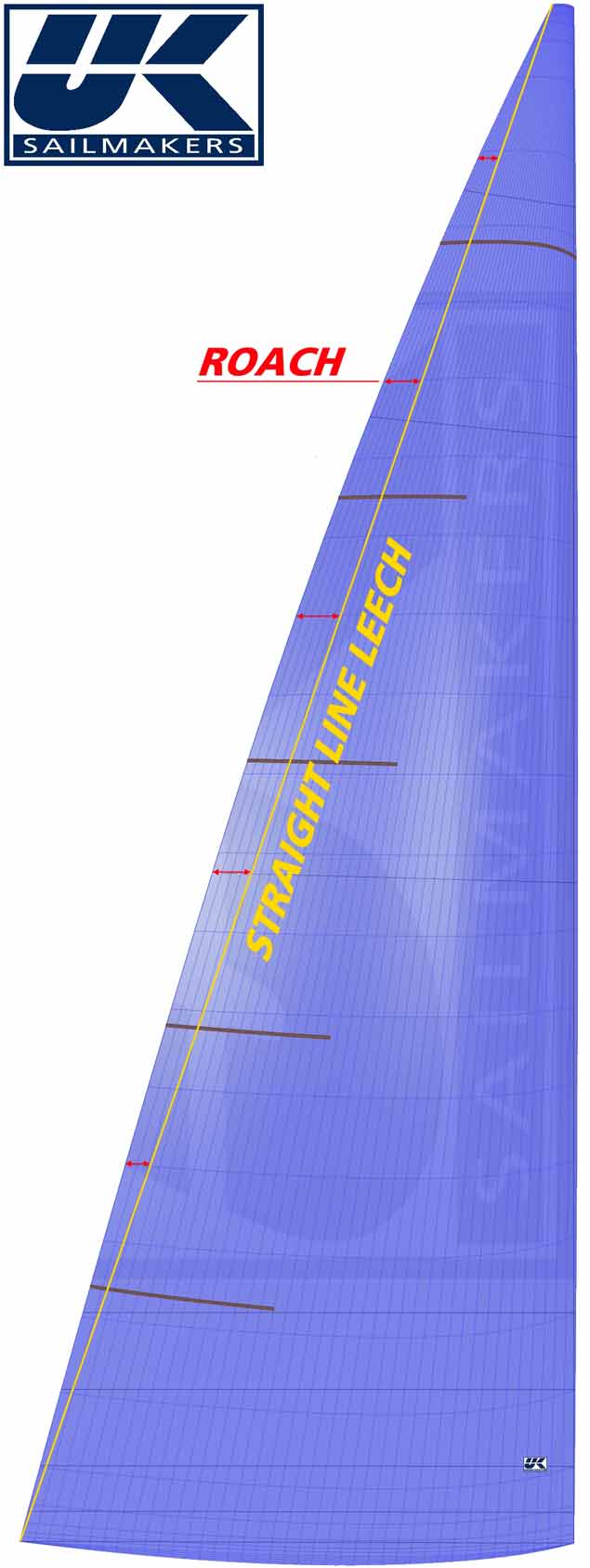

The Roach of your mainsail is the area which lies outside its straight line leech

The Roach of your mainsail is the area which lies outside its straight line leech

Almost all sails are designed and built with positive roach (the exception being furling mainsails and genoas). Roach is the area of the sail which lies outside the straight line leech.

If you go sailing without your battens in; when you pull on your mainsheet the tension will be applied along the straight line leech. Any cloth outside this line will start flapping as it will not be supported.

With battens inserted this extra area is “propped up”. The theory is the same for non-overlapping jibs.

Battens are positioned with the stiffest battens at the bottom of the sail and the lightest at the top.

The stiffness and length of each batten is specified by the sail designer and is directly related to the amount of roach in the sail.

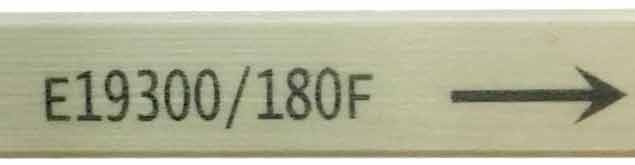

There are three main category of batten – tapered battens, contract battens, and un-tapered battens. We supply racing spec RBS epoxy (or carbon) battens with our racing sails. These have coding which specify their material, width, stiffness, stock length, and category/type. So for example:

A 19mm 1.8m long RBS Expoxy leech batten

A 19mm 1.8m long RBS Expoxy leech batten

The E (above) is for epoxy. 19mm width, 300 stiffness, 180cm length, F for “flex” ie a tapered leech batten.

Next time you are battening your sails take a look for these numbers. The high stiffness F battens should be towards the bottom – an example progression would be 300 – 265 – 265 – 230.

Note: The arrow should be pointing towards the luff!

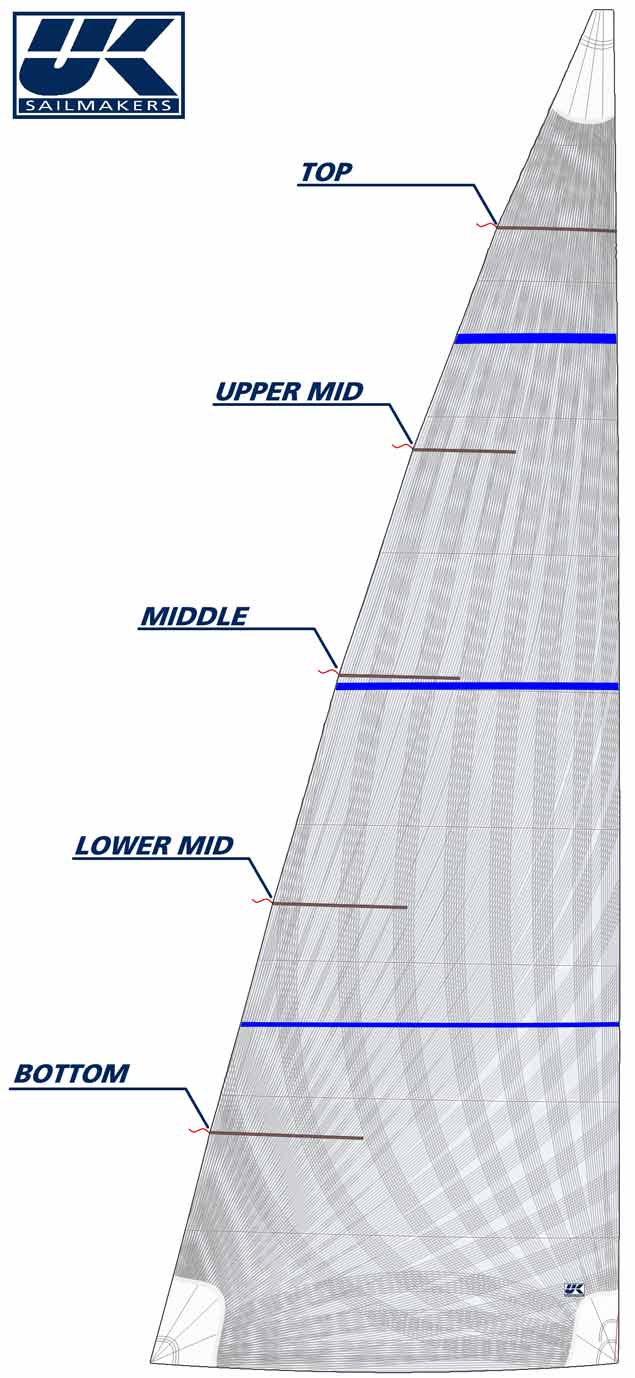

We use a labelling system of top, upper mid, middle, lower mid, bottom. With this system there is no confusion. If your sail has four battens instead of five then the “middle” is dropped so you end up with top, upper mid, lower mid, and bottom.

Simple and intuitive batten labelling method

Simple and intuitive batten labelling method

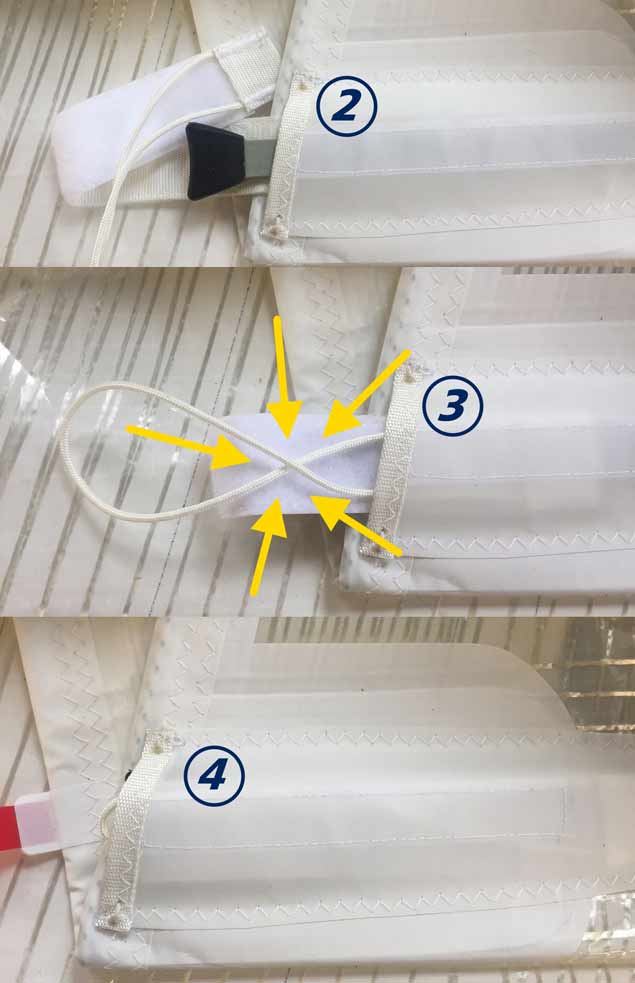

There are several batten securing options which are specified depending on the sail, personal preference, and the racing focus of the boat. The most common, due to their simplicity, are Velcro push in tabs.

The most important things to remember when fitting a batten with a Velcro tab system:

- The more flexible end of the batten should be closest to the luff. Thick end at the leech.

- Make life easier for yourself, leave the batten sticking out a little to insert the Velcro tab.

- Put one twist in the removal rope to stop the Velcro tab from twisting and jamming when removing the battens.

- Push the tab in good and firm with the removal rope tucked away but still within reach.

- Break the Velcro using your batten poker for easy removal.

Next time someone asks you to batten a sail you can have absolute confidence that you know you’re doing it right. There is nothing more painful than a batten in the wrong way round!

Dropping Your Sails

Before you drop your sails – ease the leech lines off fully, release sheet tension to unload the luff of a headsail, release both outhaul and vang to unload a mainsail, and never pull a sail down by its leech – always use the luff!

The Foil and its Balls

No one enjoys luff tape tears – least of all sailmakers! If you’re using a racing foil you should have a Monkey’s Balls or pre-feeder. This is an essential piece of equipment, and it’s setup is critical for avoiding luff tape tears.

A Harken Carbon Foil - note the secure pre-feeder and taped spacers

A Harken Carbon Foil - note the secure pre-feeder and taped spacers

- The start of the foil itself should be 1.1m above the deck.

- The pre-feeder should be 300mm below the entry to the foil.

- The pre-feeder should be tied tight to the forestay and taped – not on a string or bungee.

- The foil should not be able to move up and down on your forestay – it should have taped spacers above and below the foil.

- When hoisting your headsails; raise the sail completely and tension the halyard before sheeting on. This is a major cause of luff tape and foil damage.

- When at max hoist luff tape on your headsails can be slit at the position of the pre-feeder – allowing it to exit. This is essential to stop the sail bunching between the foil and the feeder while being dropped. This slit should be done by your sailmaker – not with a knife and a lighter!

The pre-feeder should act as a replacement for your bowman during hoists. It holds the sail forward so it feeds parallel to the forestay and into the foil. Try to bunch the luff of the sail on the bow and never sheet on early.

Rolling Your Sails

Boom folding or race packing your sails while at an event is fine. When going into storage for any extended period you should roll your sails. Use these two quick tips for easy rolling and happy sails

Fold to the middle camber stripe and begin your roll

Fold to the middle camber stripe and begin your roll

- Begin your roll at the middle camber stripe – this will ensure your headboard does not end up inside the roll where it can potentially cause damage. This is especially true for mainsails.

- Roll together to ensure the battens remain parallel. This results in a tighter and more secure roll.

- When unrolling simply start from the headboard with a friend and work your way towards the middle of the sail – don’t touch the roll itself – grab the part of the leech/luff closest the deck and lift together. The sail will practically unroll itself!

Race Folding Sails

At major events you should race fold your sails ready for action.

Slab flake your mainsail on to your boom for these few days – rolling your mainsail and leaving it hanging by the side of the boom causes the sail to bunch – slabbing is kinder to the sail. Ensure the slabs are hanging about 600mm below the boom on either side. This reduces the amount of folds, reduces the harshness of the turn of the fold, and results in a more stable flake. Make sure it still fits inside your boom cover though!

Flake all your headsails so the entire luff is at the front of the bag above the tack.

- Put the bag down first!

- Grab a partner whose friendship you do not value greatly, it may be over before the folding is.

- Ideally have a third person feeding the luff side to the folder – this person is the most important of the three if present.

- Keep the luff pulled forward – the person on the leech side must move towards the luff.

- Once folded – hopefully with friendships intact – zip the bag up but do not ‘break’ the zip!

Washing Your Spinnakers

Spinnakers, despite our best efforts, sometimes end up in the water – FYI they are just as effective under water as they are in the air so get them out quick. Over a season a spinnaker can pick up a lot of salt crystals – especially in the patches – which will weigh the sail down in light airs.To solve this; get a few large containers and some sweeping brushes. Put the sweeping brush in the bin, followed by the spinnaker, followed by lots of fresh water. Leave the spinnaker soak for a few days – occasionally disturb it by churning the sweeping brush. Empty and repeat a couple of times while waiting for a suitable day to dry the spinnaker out. You will be very surprised by the positive effect it will have on your spinnaker’s performance.

Wash your Sail Bags!

Sail bags by nature take an awful beating while protecting your sails. During the off season be sure to give them some TLC by washing them on a low heat in your washing machine – this will keep the salt away from your sails and your zips running free and clear. Be sure to rinse the machine when you’re done to avoid merciless scorn.

Spinnaker Coding

We’ve all heard spinnakers being called by their code names: S2, A1, A5, S4 etc – but what do these signify? And what is the difference?

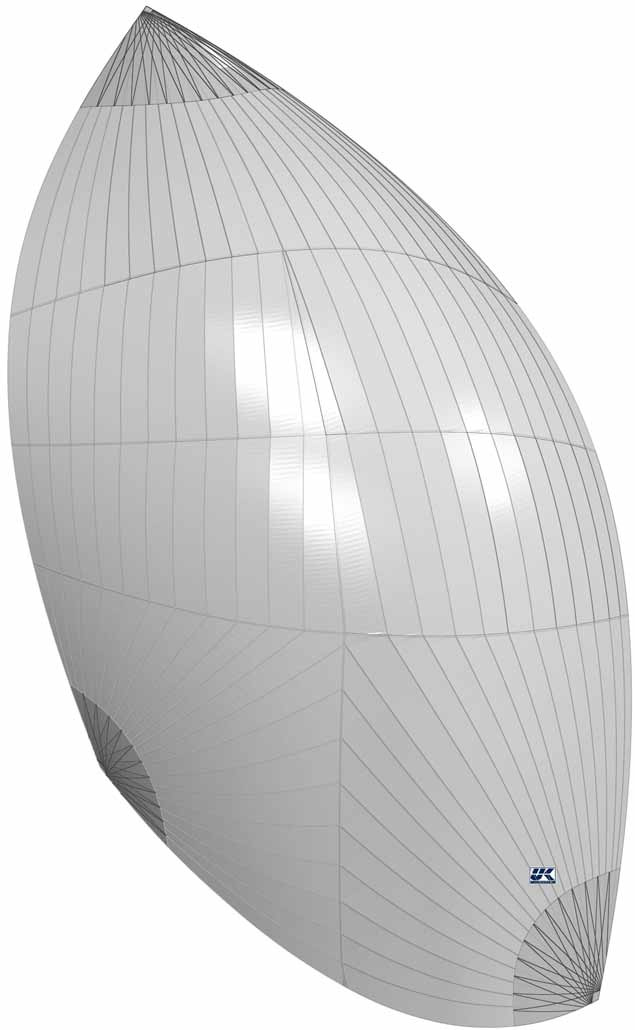

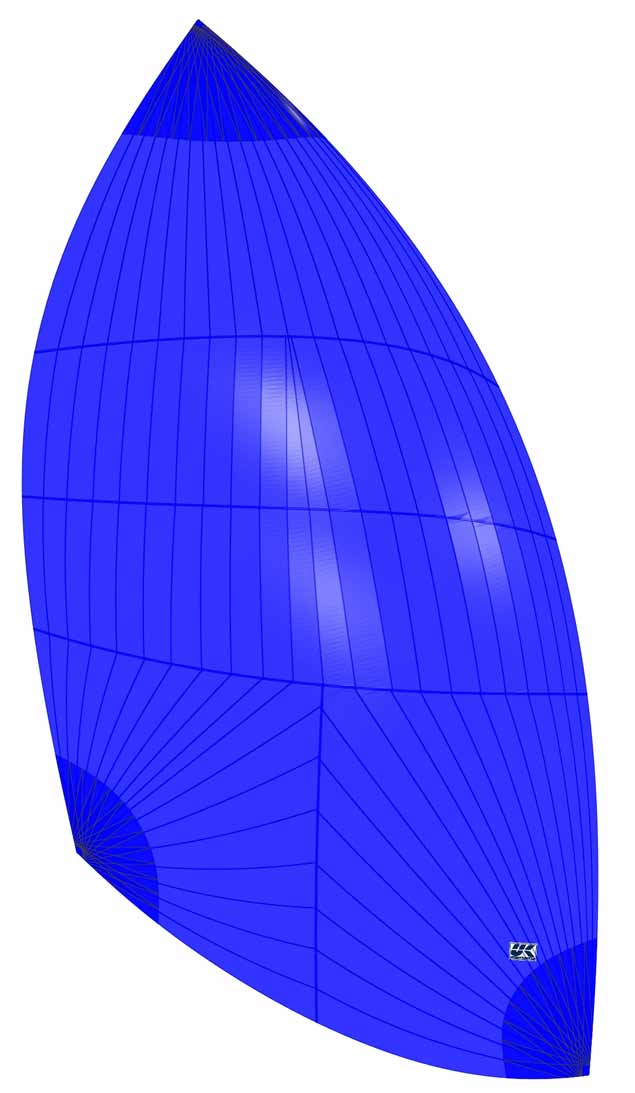

A2 Runner

A2 Runner

The letters are quite simple – S for symmetrical spinnakers – A for asymmetrical spinnakers. No rocket science there.

A1 VMG

A1 VMG

Most spinnakers fall into five mold shapes to suit different wind speeds and wind angles. In the 1-5 numbering system, the even numbers designate running shapes and the odd numbers are reaching sails. Lower numbers designate lighter wind sails and higher numbers are for higher wind speeds. Code Zeros were invented after the original numbering system; therefore they got inserted in the front.

If you haven’t already done so; you should label your spinnakers using this coding system so you can easily distinguish them at a moment’s notice. This will keep your entire crew on the same page and avoid confusion – no one likes putting the wrong kite up!

UV Strips and Furling Drums

Last, but certainly not least, we will take a quick look at UV strips.

- This is what your furled Genoa should look like - not a hint of white sailcloth - beware of white UV strips!

- This is what your furled Genoa should look like - not a hint of white sailcloth - beware of white UV strips!

Any furling headsail which stays on its foil for any longer than a day’s racing must have a UV strip fitted. The most damaging element by far to any sail is ultra violet rays from the sun. There is very little we can do to fully prevent this damage – the best solution is a sacrificial UV strip. This canvas strip takes the brunt of the UV rays while your sail is furled – performing the exact same role as your boom cover. This strip can be replaced periodically to preserve the sailcloth beneath it.

One of the most common mistakes we see in our loft is sails being furled the wrong way! This can easily happen at the end of the season. You drop your sail and pack away for the winter. When you return to the boat in Spring and maybe unload the furling line – reload it a different way – and suddenly your UV strip is on the inside and your precious sail cloth is exposed!

This is something that we see time and time again – and can be fatal for your sails. Check your UV strip is covering your sail, and your boom cover for that matter, and bring them in for regular maintenance to stay ahead of the game.

Graham Curran - Sailmaker for UK Sailmakers Ireland (@thatproyouknow)

For similar hints and tips follow our facebook page: UK Sailmakers Ireland

For the next article in the series, Mark Mansfield will follow up his Fractional Rig Tune explanation with a breakdown of how to 'mode your rig' for different conditions; and how to change 'modes' as the conditions require.