In Grand Prix classes throughout the sport of sailing, it is well known that sheeting angles are becoming tighter and tighter – modern TP52s have jib sheeting angles as close as 4 degrees off the centreline. The J109 class in Ireland is a growing and competitive fleet so we felt it necessary to take a fresh look at the sail plan and systems aboard the now nearly fifteen-year-old design with an aim to improving performance.

The J109 have evolved significantly over the past fourteen years. The most visible change has been the shift to a non-overlapping jib setup for optimum IRC performance. This shift in sailplan has a significant effect on the boat’s light air performance due the headsail area reduction.

To compensate for this reduction in power the class uses an inhauling system – this narrows the slot between the mainsail and headsail, in turn increasing the power of the entire sail plan. Up until now the common inhaul point has been the edge of the coach roof – approximately 9° sheeting angle. This is effective in true wind speeds of 15 knots and above – but below this the boat is still relatively starved for power when compared to their genoa flying predecessors – we believe further performance is attainable.

During the winter of 2018 UK Sailmakers Ireland, in conjunction with Pat Considine of UK Sailmakers Chicago, carried out a Fluid-Structure Interaction (FSI) test cycle to determine the effectiveness of jib inhauling to a sheeting angle of 6° - just inside the halyard turning blocks on a standard J109.

It quickly became clear that simply raising the clew of an existing sail and inhauling it harder will not produce a driving force gain. In fact inhauling this hard with a standard jib actually slows the boat below the base lines numbers from the initial set up test. A new design approach is required.

Below we detail the process of an FSI study – and present some of our findings and results.

The Process – Simplified

For the purposes of this article we have simplified the FSI testing process to a number of high level steps.

Target Conditions and Baseline Polars

We decided on a specific set of conditions in which we believed our inhauled setup would perform best – this is 10-12 knots in a flat sea-state. These conditions would allow an amateur helm to steer to the tighter sheeting angle without dropping out of the groove.

With our target weather conditions decided we now gather and input our J109 polar data for the test case. Variables include, but are not limited to, heel angle, leeway, boat speed, wind direction etc.

Design

With our target conditions determined and our polars set we now move on to the design phase.

Our standard J109 class mainsail design is used throughout the testing process – this is consistent and does not change.

As we believe this is a specialised light wind sail we begin with a J1 mould for the jib. Deeper than the standard J109 class jib, which is a crossover between a J1 and J2, the new design is deep with twist for power in light airs.

Initial Setup and Setting the Baseline

With our sail designs selected, we now virtually configure our J109 for sailing in the 10-12 knot conditions present in our test case.

We set the rake, mast bend, sheet tension, halyard tension, outhaul, jib car position, backstay tension etc until we reach the optimum settings –producing the maximum amount of lift for the least amount of drag. To get to this optimum setting requires an iterative process of adjusting, testing, re-adjusting, re-testing etc. This is where the skill and experience of the designer really come in to play to reach the fastest setting possible.

One of the key things in this phase of testing was to set the inhauler so the clew our J1 jib to be touching the coach roof coaming of the cabin top. This places the jib at a sheeting angle of 9° from the centreline.

In this phase, we are looking for performance trends. As we make changes and re-test we expect the trend to be positive – either an increase in lift, or a reduction in drag, both leading to positive outcomes. Once the trend begins to plateau or even turn negative we know we have reached the optimum trim for this particular design.

Once the designer can no longer improve the virtual performance of the boat by adjusting sail controls the iterative process stops. A series of comprehensive FSI runs are then done on this setup to provide a baseline set of data to compare and contrast the next round of test against.

Design Iteration

We now implement our suggested improvements to our J1 jib design. Our aim is to sheet this sail at an angle of 6° from the centreline of the boat – this is just inside the halyard leading blocks of the standard J109 deck layout. We will call our new design the ‘JX’ headsail.

Sheeting to a 6° angle, with no change in jib design, causes the slot of the sail plan to close and driving force to be lost due to increased drag. Simply raising the clew of an existing sail and inhauling it harder will not produce a driving force gain. In fact inhauling this hard with a standard jib actually slows the boat below the base lines numbers from the initial set up test. A new design approach is required.

Design Twist

When a sailor hears twist he or she usually thinks of easing the sheet to induce it. What many sailors don’t realise is that there is twist designed into the shape of every sail – they are made to sail with an optimum amount of twist. For example the standard mainsail design twist is approximately 12°.

Returning to our testing we begin to increase the amount of design twist in our ‘JX’ headsail. As the design twist increases drag reduces, and driving force increases. While adjusting the design twist the virtual trim of the jib is also adjusted to keep the sail trimmed optimally.

Once we see the lift/drag/driving force trend begin to plateau we reach optimum design twist.

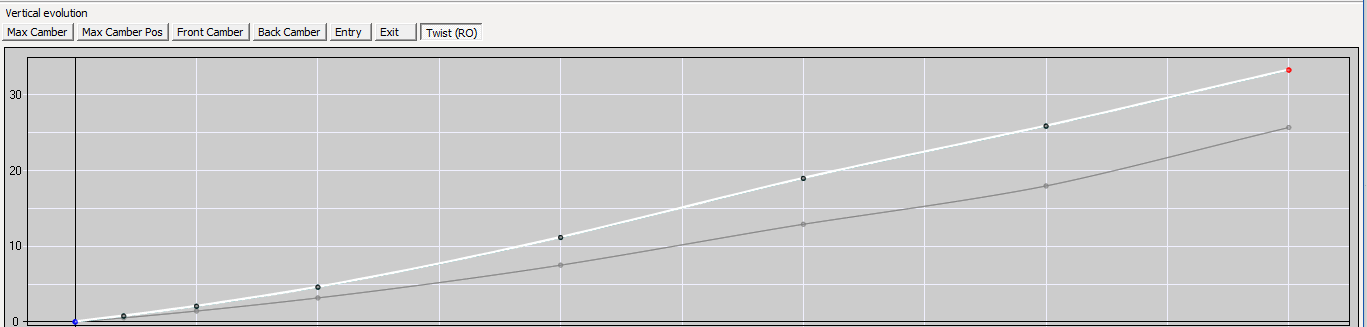

Figure 1 - Vertical distribution of twist

Figure 1 - Vertical distribution of twist

We settle on a maximum of 7.6° increase in design twist distributed vertically. This allows the sail to maintain a consistent twist relationship with the mainsail at the smaller sheeting angle of 6°.

Max Camber Position

When inhauling at tight angles it is very important not to ‘shut’ the slot with a return off the headsail leech. A leech hook or return at such tight sheeting angles causes an enormous amount of drag while also clogging up the slot. A straight exit off the leech is needed. A leech hook or return is often cause by the depth of the headsail moving aft towards the leech. This causes the entry to become fine and the leech to close in towards the mainsail – keeping the max camber position forward in the sail is essential.

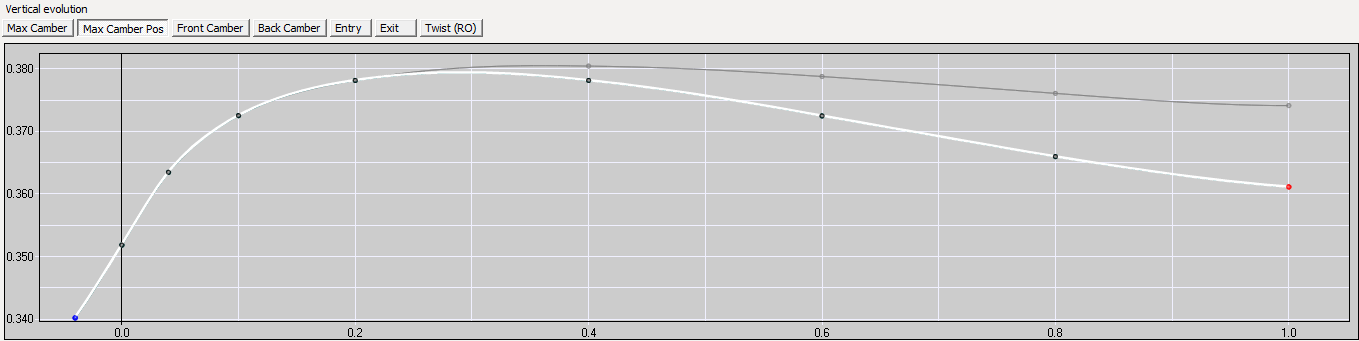

Figure 2 - Max camber position

Figure 2 - Max camber position

As we have increased our design twist and brought our sheeting angle well in board we now adjust the max camber position of the sail. Over several iterations we found a gain in moving the max camber position forward. This prevents the upper sections of the headsail shutting the slot.

Camber

Several camber adjustments were made in order to keep the straight exit from the leech of the sail. Notably a reduction in aft camber in the sail’s lower sections.

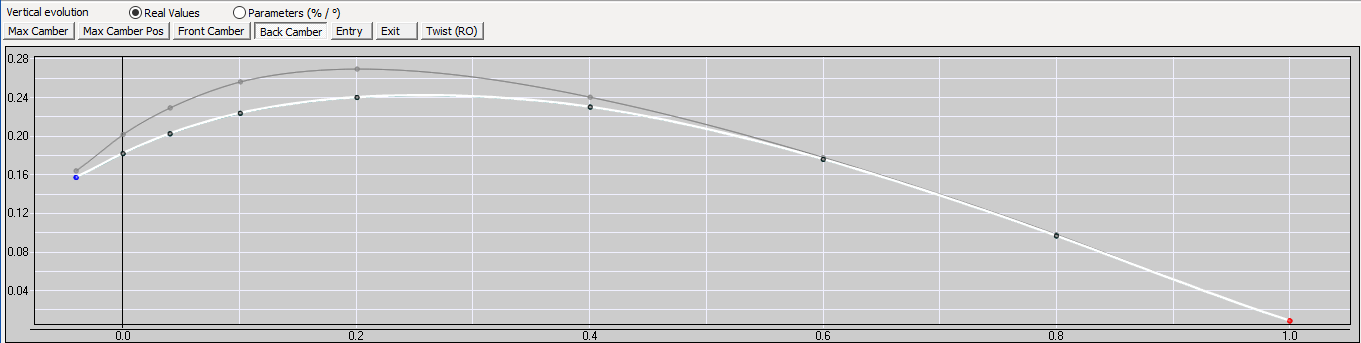

Figure 3 - Aft camber adjustments

Figure 3 - Aft camber adjustments

As a result, the overall camber in the lower sections of the sail was also reduced. These flatter sections ensure a straight leech exit at maximum inhauling. The lower depth is now controlled by the positioning of the trim point ie the clew position controlled by the trimmer.

This allows a narrower sheeting angle without an increase in mainsail backwinding.

Results - Comparison to the Baseline

Having iterated over our ‘JX’ design for many hours we settle on the new design. We run the same comprehensive set of FSI tests as were run to provide our baseline set of figures. Below we go through some of our findings.

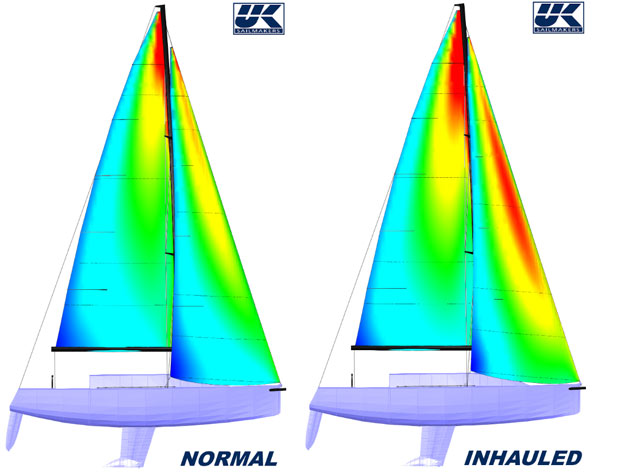

Pressure map comparison

Pressure map comparison

Above you can see our J109 test platform. The left picture is our baseline J1 headsail design. To the right is our new ‘JX’ headsail design. This picture is a leeward view of the sails’ pressure mapping. It can be clearly seen that the ‘JX’ design produces a significant increase in pressure differential when compared to the J1 design.

Not only is there a pressure differential change on the headsail itself but also on the mainsail. This shows how harder inhauling can improve the effectiveness and efficiency of the entire sail plan.

Lift, Drag, and Driving Force

In our FSI testing runs the sail plan is trimmed for proper flow across the luff in 12 knots true wind speed at 37.5° true wind angle. Boat speed of 6.34 knots with 18.8 degrees of heel and 3 degrees of leeway.

Mainsail shape and trim remains constant throughout testing in order to isolate the jib design adjustments.

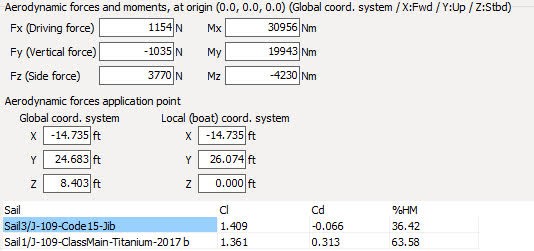

Figure 5 - Baseline performance numbers

Figure 5 - Baseline performance numbers

Our initial FSI testing provided some baseline numbers for our new design testing.

Numbers of note:

- Fx (Driving Force): 1154N

- Fz (Side Force): 3770N

- Cl (Lift): 2.77

- Cd (Drag): 0.247

Our subsequent FSI testing runs provided a set of numbers for our new ‘JX’ design. Notable numbers below with deltas from previous testing highlighted in green and red for positive and negative changes accordingly.

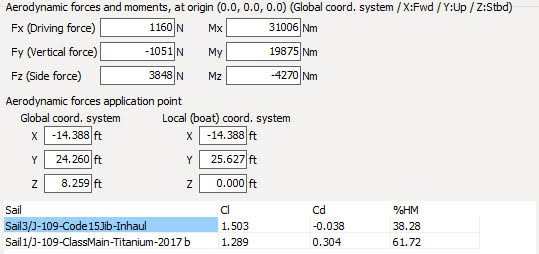

Figure 6 - 'JX' headsail performance numbers

Figure 6 - 'JX' headsail performance numbers

- Fx (Driving Force): 1160N (+1%)

- Fz (Side Force): 3848N (+2%)

- Cl (Lift): 2.79 (+1%)

- Cd (Drag): 0.266 (+7.6%)

With the new ‘JX’ design we are able to achieve a 1% increase in driving force and a 1% increase in lift coefficient of the sail plan.

There is, of course, the associated increase in drag and heeling moment but in 12 knots of true wind speed these can be overcome by righting moment – hike harder.

The other option is to turn the increased lift into height instead of fast forward.

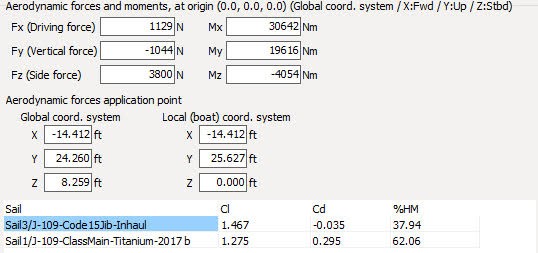

At a true wind angle of 36.5° we maintain the same total coefficient of lift but lose some driving force as a result.

This shows the versatility of the ‘JX’ design. More power and efficiency in normal mode and still very efficient in height mode.

Figure 7 - 'JX' headsail height mode performance numbers

Figure 7 - 'JX' headsail height mode performance numbers

Mainsail

It must be noted that the mainsail trim was not altered between FSI tests. In reality when at a smaller sheeting angle the mainsail would be brought further to windward to maintain the open slot. This would produce an increase in lift coefficient, side force, and drag. All of which could be overcome by more hiking.

As we all know in this wind speed – whoever gets their crew hiking fully first usually wins.

From Virtual to Real World

In April 2018 UK Sailmakers Ireland’s Barry Hayes, Graham Curran, and Mark Mansfield carried out a two-boat testing session with the newly developed ‘JX’ headsail design as reported by Afloat.ie here.

Figure 8 - Two boat testing on Dun Laoghaire Bay

Figure 8 - Two boat testing on Dun Laoghaire Bay

We used two well-matched J109s, including the reigning Irish Class and IRC National Champion “Joker II”.

The test was carried out in ideal conditions with 10-12 knots true wind speed and flat water on Dublin’s Dun Laoghaire bay.

The ‘JX’ headsail was used on both boats throughout testing – with the Joker II’s Championship winning headsail being swapped also. “JEDI” was using a UK Sailmaker’s Uni-Titanium mainsail while “Joker II” was using her own class mainsail.

Several hours we spent upwind testing – lining up bow to bow in the same breeze.

There was a notable difference between the two headsail when both were inhauled hard to a 6° sheeting angle. The ‘JX’ jib remained twisted and fast while the other jib tended to shut out early and cause excess back winding of both mainsails.

Although hard to determine a conclusive advantage it was noted by both helms, independently, that the boat was easier to helm at the tight 6° sheeting angle using the ‘JX’ headsail.

Material Improvements

The J109 is a 14 year old design – you may ask, why wasn’t this done sooner?

The reality is that the material improvements in sailmaking over the last decade have been immense. No so much in what materials are being used, these are fairly constant, more so how they are combined in cloth technology. UK Sailmakers’ Uni-Titanium cloth allows us to build sails with constant draft, depth, and clean leech exits over a large range of wind conditions. Where Dacron or string sails of old would deform and deepen as wind speed increases; Uni-Titanium remains rigid in its design shape. This is essential to modern sail design, particularly sheeting headsails to narrow angles.

Conclusion

Throughout our FSI testing period, it became clear that at closer sheeting angle would improve the overall performance and efficiency of the J109 sail plan. However, we were not convinced that this would be the case in a real-world situation out of the virtual test box.

After on the water test, and several major regattas and a Round Ireland race, we are happy to conclude that the ‘JX’ headsail development has been a success.

"We are happy to conclude that the ‘JX’ headsail development has been a success"

There is much more to inhauling than you may realise. It is common to think of your headsail independently – but it is just one cog in the machine. The relationship between it and the mainsail, and between the sail plan and the underwater profile of the boat must all be considered – they all combine to produce a force which moves you forward, preferably faster than your opponent. If any of these relationships are out of balance then the entire system will begin to crumble.

What is next?

Our virtual and on-the-water testing produced other potential performance improvements to pursue – we are continuing our investment in the J109 class and sailors will be seeing these developments, and more, on Irish waters throughout the coming months.