Displaying items by tag: UK Sailmakers Ireland

Offshore Worlds 2018 - The True Pinnacle of Cruiser Racing

UK Sails Ireland sailmaker Graham Curran who competed on 'Fools Gold', Ireland's sole entry at the Offshore Sailing World Championships 2018, reviews the event that was truly the pinnacle of cruiser racing in Europe and concludes IRC and ORC need to work closely together, for the benefit of both organisations, so Irish/UK based sailors can compete uninhibited in Europe, and vice versa.

Offshore Sailing Worlds 2018

The Offshore Sailing World Championship is the premier cruiser/racer keelboat event of the year. It was clear by early 2018 that the competition would be fierce with Class C oversubscribed within a week of entries opening. This resulted in a forty-six boat fleet – no split – forty-six ~35ft cruiser racers on one start line. Class C consisted of a wide variety of yachts – many of which would be familiar to Irish sailors: X-37, J109, X-362 Sport, Beneteau 36.7 (Mod), Farr 30 etc. The class also included several one-off designs built specifically to win this event.

IRC / ORC Balance

The rating system used for the event was an IRC/ORC result combination system. This meant that teams needed to optimise to a good middle ground between the two rating systems. The event in effect was an experiment for the IRC and ORC rating boards to understand the differences in their rules and to help bring them together for closer, more inclusive racing in the future. As racing began, it became clear that some performed better than others.

IRC vs ORC

The IRC system used for this event is the one we all know well in Ireland. Sail and yacht designers know what works and what doesn’t for the IRC rule.

ORC takes the same measurements IRC does, but also includes many extra measurements such as headboard widths of sails, spinnaker halyard hoist height, inclined waterline lengths and overhangs, rig weight etc. ORC then runs these measurements through their VPP model to determine a yacht's performance across a variety of wind ranges (low/medium/high). With ORC you actually have three separate ratings as opposed to the single IRC rating.

On the day of racing, just before the start, the race officer decides which ORC rating he will apply to the fleet depending on the prevailing conditions. This, in theory, provides a fairer rating system for all boats – and encourages designers to produce yachts that are well rounded across all conditions.

An implication of IRC and ORC ratings

The event was not going to be won by straight bullets across the board – no one was going to be able to achieve that in a tight forty-nine boat fleet. The most important factor was decided long before racing began – IRC and ORC ratings – specifically how they compared, interacted and combined.

Being strong in one system and weak in the other resulted in high final numbers. For example – if Boat A finishes with a 1st in ORC and 7th in IRC the final score is 8 points. Boat B has a 3nd in ORC and a 4th in IRC has a final score of 7 points. The consistency of boat B across both handicap systems means she wins the day.

W36 “Hubo”

Hubo is a one-off built for this year’s World Championship. UK Sailmakers Ireland has been involved with this project since its inception. From design through to realisation, construction, commissioning, tuning, and iterative performance improvement.

Hubo

Hubo

Hubo performed well across all conditions and was lightning quick downwind. Her square top mainsail provided ample power in the light choppy conditions off The Hague while her underwater profile allowed her to slip through the strong tide just offshore. Although disappointed with their overall position at the end of the event the team are very pleased with the boat’s performance. Hubo currently leads the Dutch National ORC Championship series. With many lessons learned from this year’s World Championship, she will be back strong to compete for many years to come.

Hubo is powered by UK Sailmakers a Uni-Titanium upwind sail package and Matrix spinnakers.

“Our journey with UK Sailmakers has been truly special. Not shying away from innovation, we designed a sustainable racer for the World Championship 2018 requiring an equally bold approach from our sailmaker. Our wishes were their command and in the unbelievably short period between launch and the Worlds, when we were tuning for speed, the designers of UK Sailmakers just knew how to translate those findings into seamlessly designed sails with the right cloth. The team calls the A0 a ‘secret weapon’ for a reason.

Perfect teamwork and we are impressed with the knowledge in-house, which we have stretched to the max. The attention to detail shows me, a professional sailmaking craftmanship at its finest” Erik Van Vuuren – Owner

Archambault A35 “Fools Gold”

In September 2017, after a successful Irish season, Robert McConnell decided it was time for a new challenge for his A35 “Fools Gold” team. The 2018 calendar would include Wave Regatta in Howth, the IRC Europeans in Cowes in June, culminating in the Offshore Sailing Worlds in The Hague in mid-July.

Fools Gold entered the World Championships, as the sole Irish representative, after an encouraging fourth place finish at the IRC Europeans in Cowes. We felt confident, but our ORC performance was still unknown.

The A35 has wide full aft hull sections which provide ample righting moment when upwind and exceptional stability downwind. The downside of this shape is increased wetted surface area – drag. To overcome this more sail area is needed, especially upwind. This upwind sail area is effectively taxed under IRC so, in order to remain handicap competitive in prevailing Irish conditions, a compromise must be made. This optimisation produces a “magic number” of approximately eight knots of true wind speed, in which an A35 is at full power and IRC competitive. Under the magic eight knots it will be a struggle for power.

Fools Gold

Fools Gold

ORC, being a very detailed rule, takes the above into account, but also simulates the boat’s performance in different conditions. Theoretical values are deduced from the ORC VPP such as acceleration, upwind VMG, beat apparent wind angles, gybe angles etc. Your rating is then determined using these theoretical values derived from the VPP simulation for a range of conditions.

As the inshore racing began, it became evident that the A35 is not kindly rated in the light ORC wind range – based of the simulated values attained. The numbers being seen on the water were in contradiction to the results produced by the ORC VPP.

As the inaugural combined IRC ORC World Championships, the event was an experiment to be learned from. After much discussion with the ORC measurers – with the assistance of IRC – there were some inconsistencies found and some small adjustments made, although not enough to rectify the substantial points differential between IRC and ORC results.

After three days of medium strength conditions, Fools Gold was in a solid 15th position with aims at top 10 by the end of the week. Unfortunately, the forecast had other ideas with the final two days of racing being light and fickle. Great downwind pace could not outweigh the difficulty of holding upwind lanes in these light conditions.

If an A35 were to focus solely on this event then the handicap optimisation would need to be revisited and sail area increased, certainly to the detriment of her IRC competitiveness. The boat would then be uncompetitive in home waters.

Although disappointed with the final 22nd place result Rob and crew are delighted with the event and the experience gained. The Offshore Sailing Worlds 2018 was truly the pinnacle of cruiser racing in Europe. The yachts present, the calibre of competitors, and the quality of the racing were like nothing experienced before. Plans are afoot to return and have another shot at the title.

1st - J112E “J Lance 12”

J Lance 12, having dominated the IRC Europeans, was the favourite entering the World Championships. She is no standard J112E. J Lance 12 is the factory works boat for the J112E line. She has an ultra-high modulus carbon rig, a lighter hull, and a symmetrical spinnaker setup.

She had won the European Championships with ease across a variety of conditions. She was fast, well sailed, and well optimised to both IRC and ORC with rarely more than 4 points differential between her IRC / ORC results.

J Lance 12

J Lance 12

She sailed with only six crew for the World Championships where most were sailing with eight. The Hague is a generally light air venue in July, this was key to her success.

Her high upwind mode allowed her to hold tight lanes in the busy fleet and off the start line while her symmetrical spinnaker setup provided her options an asymmetric counterpart would not have.

All of the above combined with a well oiled and experienced crew resulted in a deserved World Championship win.

2nd – ITALIA 9.98 “IMMAC FRAM”

The Italia 9.98 is a seasoned ORC World Championship winning design having won the 2015 and 2016 ORCi World Championships – however, they had not raced extensively under IRC.

The Italia’s sleek lines give her a shorted waterline when flat in a light breeze – reducing her wetted surface and benefiting her handicap – particularly under IRC. Her well-optimised sail plan, deck configuration, cockpit ergonomics and symmetric spinnaker setup make her an intuitive boat to sail.

IMMAC FRAM

IMMAC FRAM

We found the Italia 9.98 to be particularly fast downwind while being able to hold her own upwind against the majority of the fleet. Provided she sailed the correct lanes in clear air on the first beat she was generally gaining places on the downwind legs – regularly picking up places on the final downwind to the finish.

Although not as well optimised as J Lance 12, IMMAC FRAM was able to produce consistent results across both IRC and ORC, particularly in the medium ORC conditions. Occasionally she would have a large 10 point differential between her results when she finished deeper in the fleet. This hurt her chances of overall victory.

3rd - First 36.7 MOD “Team Pro4u”

This heavily modified First 36.7 has been with her owner for 14 years and has been heavily modified to remain competitive. She is a multiple national and Europeans ORCi Champion and has been on the podium of the ORCi Worlds several times previously.

She is tiller driven with a new keel and rudder by Farr Yacht Design – with another potential keel modification next year. A high modulus carbon rig with curved wing spreaders to increase her fore triangle area. Her cockpit has been extended aft to reduce weight and improve crew ergonomics. She sails with a non-overlapping jib configuration with fine tune system on her in-haulers and halyard so the trimmer from his rail hiking position can alter both. She sailed with a symmetric spinnaker configuration but has bowsprit for a Code Zero/Asymmetric option although she did not run with this for the World Championships.

PRO4U

PRO4U

The non-overlapping configuration certainly worked for her, but only in conjunction with the high modulus carbon rig and the curved wing spreaders. This allows enough headsail area to balance the mainsail and keel configuration.

Pro4u began the week very strong with two excellent results in the offshore portion of the event. In medium/high ORC ranges, she is extremely quick – especially in the flat water around The Hague. Later in the week when the breeze began to slacken and a slight chop developed, she began to struggle upwind, especially with J Lance 12 breathing down her neck.

Pro4u had held the event lead for the entire event until the last race. J Lace 12 match raced her at the start and held her at the back of the fleet in tricky light conditions – there was no way back. J Lace 12 was able to claim overall victory with a better discard.

IRC ORC World Sailing Championships 2018 Conclusion

The IRC ORC World Sailing Championships 2018 was a first attempt combination of two similar but unique rating rules. It was successful in its goal of bringing some of the best yachts and sailors in Europe together on one unified racecourse. However, there are many improvements needed before this event can truly succeed. IRC and ORC need to work closely together, for the benefit of both organisations, to bring the rating systems closer together. Each has their own agenda and vision for how to grow our sport but for the benefit of all sailors, their customers, there need to be bridges built. The goal should be compatible, interchangeable ratings so that Irish/UK based sailors can compete uninhibited in Europe, and vice versa.

UK Sails Ireland Provide Sails for Two Boats at Inaugural IRC/ORC Combined Worlds at The Hague

UK Sails Ireland has put sails on two very competitive entries for the inaugural IRC/ORC worlds, commencing in the Hague in Holland this weekend. The boats are Rob McConnell's A35 'Fools Gold' from Dunmore East, with a full Irish crew and Erik Van Vuuren's Waarschip 36 named 'Hubo'.

Fools Gold, winner of last year's Sovereigns Cup, will sport a full UK Sails Ireland Inventory of Uni Titanium Main and Headsails and will also have UK Spinnakers. On her way to this event she also competed in the IRC Europeans in Cowes and had a creditable fourth place overall in her class.

For the ORC/IRC World Championships, there is an extremely large class of 50 boats from over 10 countries and this will test the teams big fleet sailing abilities.

The crew for the event is:

Rob Kelly - Bow

Bryan O' Donnell - Mast

Lisa Tait - Pit

Graham Curran - Trim 1

Dougie Power - Trim 2

Roy Darrer - Helmsman

Robert McConnell - Mainsail (Skipper)

Tom Fitzpatrick – Tactician

Fools Gold sailing in Sovereigns Week

Fools Gold sailing in Sovereigns Week

It is both an inshore and offshore event. The opening offshore race on Sunday is comprised of two sections. The first half of the race will be scored separately while the overall race will also be scored separately. Following these offshore races, there will be three days of inshore racing.

The Other UK Sails Ireland Boat competing, is Erik Van Vuuren's Waarschip 36 called Hubo. Designed by a Dutch Naval Architect for a Dutch owner, specifically to compete at the IRC/ORC Worlds. Barry Hayes, Director UK Sails Ireland, was contacted to head the Sail and Rig Design for this new project and in particular to develop the sails and "Lead" for the boat. The “Lead" is the technical name given to the balance of the boat. When designing a completely new boat it is important that the mast and keel placing and sail setup are very accurate to ensure the balance on the helm is correct.

Normally this will be done in the design phase and then when the boat hits the water, this can change quite significantly based on how the boat performs on the water. This was the case with this boat and Barry Hayes has been over to Holland a number of times to perfect the sails and balance of the boat.

Hubo is sporting a full Suit of Uk Ireland designed Uni Titanium Mainsail and Jibs, plus Uk downwind sails including a Zero, Jib Staysail, Spinnaker staysail and various Asymmetric and Symmetrical spinnakers.

Hubo in upwind mode

Hubo in upwind mode

Over 80 boats will compete in the 3 Classes at this event, and they range from superfast TP 52s in Class One down to A Dehler 33 which is the smallest boat in Class 3. Class 3 is the class that both Fools Gold and Hubo will compete in, and it will have 50 entries, making it by far the most competitive class in the event.

The event website is here and the results can be found within that site.

Uk Sails Ireland Director, Graham Curran, will be trimming on Fools Gold and will keep us informed of their progress and how the regatta is working out.

Meanwhile, UK Sails Ireland will have a full presence at Volvo Cork Week with Mark Mansfield and Barry Hayes sailing on George Sisk's Wow in what has turned out to be a very competitive class one fleet.

With the advent of high–tech construction, most upwind sails are now being manufactured in specialist facilities in the likes of Hong Kong, Sri Lanka and South Africa. However, some sails are still being made in Ireland in a few lofts. One of these is UK sails in Crosshaven which still has the ability to build sails in Ireland. Here, Barry Hayes, Director of UK Sailmakers Ireland, explains how sails are designed and constructed. The firm recently provided four new downwind sails for Paul O'Higgins JPK 10.80 Rockabill VI and two of these were manufactured in Crosshaven in Cork Harbour.

High–tech upwind sails are now all made on moulds, such as the Titanium and Uni Titanium upwind sails produced by UK Sails at its uber modern new manufacturing facility in Hong Kong.

The A35 Waterford yacht Fools Gold on her way to winning Sovereigns Week in 2017 with her UK Sails Uni Titanium Main and J2 Jib Photo: Bob Bateman

The A35 Waterford yacht Fools Gold on her way to winning Sovereigns Week in 2017 with her UK Sails Uni Titanium Main and J2 Jib Photo: Bob Bateman

However, downwind sail construction has not changed significantly (apart from Code Zero sails) over the years with nylon type spinnaker cloths still being provided by the likes of Dimension and Contender.

The design of these downwind sails though has changed significantly and updated software programmes ensure that the optimum shapes are always being reproduced, whether the sails are built in Hong Kong or in Crosshaven.

UK Sails also manufactures Panel upwind sails in Crosshaven for various classes and the loft employs seven or more staff throughout the year.

So, how is a sail made from start to finish?

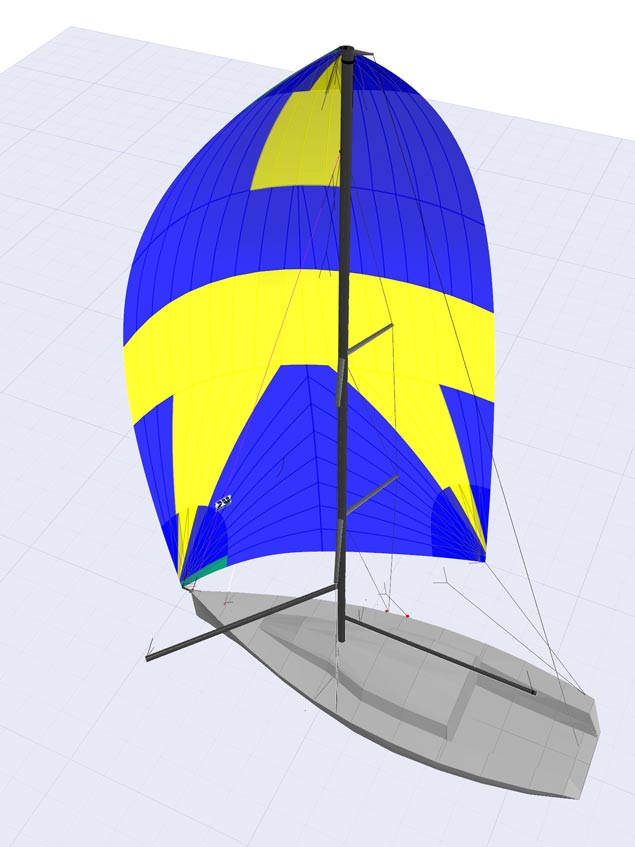

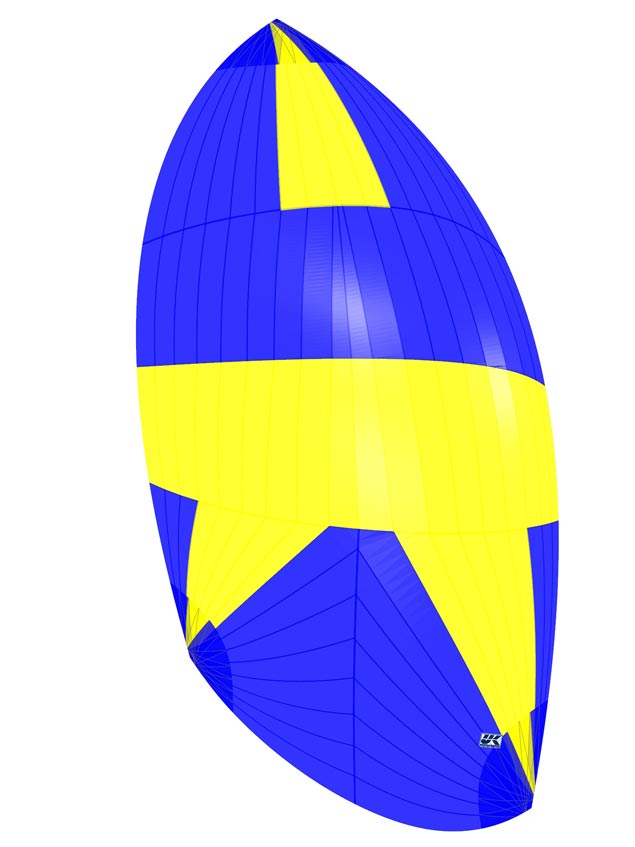

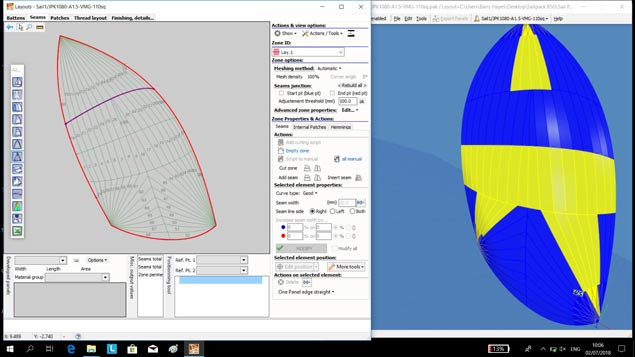

Once the customer has ordered the sail. Then we start designing the sail in 3D real-time view.

We get the measurements from the boat then input these into the design programme. They will then create a boat in a real 3D view for us to design the sail from. From this boat, we will work out the sheeting angles and the overall size of the sail.

For example, if the boat needs a new A1(asymmetric light air reaching sail) we will work out the working angle and the size based off the current working sails and give advise if that needs to be changed. Mostly spinnaker sizing works on Displacement. A heavy boat needs a bigger sail. There are limitations, however, such as mast height. If you have a heavy boat with a short mast, you cannot just increase the sail size by making it wider as there are certain ratios that work well and others don’t. Likewise, if a boat has a masthead halyard off a tall mast, and does not need a very large spinnaker because the boat is light, then that can be a problem, as you end up with tall, narrow spinnakers. In this case, it can be effective to lower the halyard position so you can then make optimum ratio sails.

3D spinnaker design

3D spinnaker design

Once we have worked out the geometry of the sail. Then we will work out the design. Size and shape. So the sail is the correct size and shape for the working angles it is being used in. From there we will work out the colours the customer wanted and the patch sizes.

The seam sizes and patch sizes are different for each boat type and boat size. This is based on years of experience, knowledge of the design and how the sail is used, such as if it is being used for offshore or inshore racing.

When all of the sail is designed we then cut out the sail on the plotter. We take each panel and nest them as tightly together as we can to keep the waste to a minimum. Its normal with a spinnaker to have, say, 10% waste for a 40-foot boat. It varies with each sail and size.

Once we have nested the cloth it is then cut out on our 46 ft cutting table called a plotter. This machine can cut out a 40-foot kite in a day (10 hours). This is a normal plotting time for a big sail. The plotter will cut each panel out, number it and draw the seams.

UK Sails plotter working on Rockabill VI's A 1.5 Spinnaker

UK Sails plotter working on Rockabill VI's A 1.5 Spinnaker

From these cut-out panels, we will put each panel together on the seaming table. This is a very critical point of the process. As the tension on each seam has to be exactly the same. You need lots of experience to do this job and it takes a really good technique. This normally takes about three to four years of experience to get this right.

Graham Curran, Director, Uk sails Ireland, attaching the panels at the seaming table

Graham Curran, Director, Uk sails Ireland, attaching the panels at the seaming table

When we stick every seam we will fly the seam by holding it up to the light to check the seam is smooth and ready to be sewn. Most sails are put together in sections. A 40–ft spinnaker will have five main sections. For a dacron headsail, it can have up to 16 panels or four sections. Having the sail in sections makes it easier for handling and putting sections together.

Once you have the panels ready they go to the sewing machine for sewing. This the tricky part as you need to really concentrate and make sure you don’t put a needle wrong. If you stitch out of the seam it will compromise the sail integrity.

Claire Morgan, Director, UK Sails Ireland, sewing the panels

Claire Morgan, Director, UK Sails Ireland, sewing the panels

All the seams will be sewn and triple stitched. Single or double depending on the size and type of sail which is specified by the designer.

Now the whole sail is together and is then faired to the size. So the luff leech and foot are smooth and a fair line.

Cleo Watkin and Graham Curran fairing the sail

Cleo Watkin and Graham Curran fairing the sail

This takes great skill and a good eye to make sure the flying shape or the sail is right. Having too much hollow or too much girth will create a sail that’s slow or too hard to trim. So this has to be correct. Getting this right takes experience and practice.

Once the outline of the sail is finished the patches go on. Each panel of the patch is glued down and sewn again onto the sail.

The laying of these patches onto the sail has to be done smoothly. So flattening the sail and adding the patches to the panels is tricky work. The sail is pinned out in different areas to make the sail flat so the patches go down correctly.

The sail then heads for finishing. The corners of the sail get all the rings, webbing and hand sewing put on the sail. This type of work gets done on the big sewing machine with a very heavy tread. It uses waxed thread so it doesn’t wear down over time. As the rings in the corners are pulled hard on different points of sailing they are the most worked parts of the sail and the main point of load.

You can see the sail on a tight reach with the sail loaded and the tack ring taking the load. You can also see the tack retriever patch and pull downline. As well as the bungy hoisting system.

After that, the sail is measured for IRC. As we are an in IHC (in-house measurement certified loft) we measure the size of the sail and if its an endorsed IRC cert or One design we put a World Sailing/ISAF sticker on the sail. This is a guarantee the sail is measured within the rating rule. This specific sticker has a specific generic number on it which certifies the sail. We also record the temperature of the sail when we measure it as this can change depending on the time of the year it's measured.

In the final photo, you can see the finished sail flying on the boat.

When you order a sail from a loft that produces sails in Ireland, apart from the obvious benefit of supporting home-produced goods, you ensure that if any changes are needed, they can be done quickly and efficiently by properly qualified sailmakers.

Barry Hayes, Director of Uk Sails Ireland, managed the Main UK Production facility for UK Sails in Hong Kong until last October and has been a sail designer with UK sails for over 15 years.

Code Zero Sails – Do You Need One?

Up to about 15 years ago, most boats were designed with big overlapping headsails, which were still pretty useful when reaching because of their size. Then it became evident that this set up was not that efficient and trying to manage very big Geneos was difficult and needed a lot of grunt to tack them. Also, the IRC rating rule seemed to be more advantageous if you reduced your headsail size to the same as the foretriangle. Barry Hayes of UK Sailmakers Ireland reports.

Boat designers then all started designing their boats with these smaller headsails which were excellent upwind, but it became evident that reaching in lighter airs was an Achilles heel for them.

The loss in power when you’re reaching with a non-overlapping headsail became a problem, so to address this issue, Code Zeros were developed. The big difference is you can normally put up 3 times more sail when you hoist a Code zero, compared to reaching with your non-overlapping Jib.

"You can put up three times more sail when you hoist a code zero, compared to reaching with your non-overlapping jib"

You will likely have seen code zeros on fast offshore yachts such as the Volvo 65 ’s, IMOCA 60’s and others. However, these Code zeros are not restricted by IRC rules. IRC imposes a restriction on these code Zero sails which means to count them as a Spinnaker the mid girth must be at least 75% the size of the foot. If you don’t have this, it is counted and rated as a Jib, which would be punitive for your rating. So all the sail designers have engineered the Code zeros to comply with this rule, and recently they have become much more efficient than they used to be.

In years gone by they were flappy leeched sails, that were not that efficient. Now technology in sailcloth and with better design, they can be made to virtually look like a Jib, but still, they are rated as a spinnaker.

As I mentioned above, it is generally used in lighter reaching conditions, when it is too tight an angle to hoist even an Asymmetric spinnaker. A code zero in 5 or 6 knots at a 50 to 70 degree wind angle is an absolute weapon, and if you find yourself in these conditions, and don’t have one of these, expect to see boats come over the horizon behind you and sail right past you, perhaps doing as much as 2 knots or more extra speed. A Code zero can also be used in more wind when the wind angle is a bit wider and can take the place of a reaching Asymmetric.

A code zero, in many conditions, can virtually go as High as a boat with just a jib. What happens is, say you are going nearly upwind in 5 or 6 knots, you may be doing just 4 knots with your jib, and because you are not going that fast your wind angle is a bit wide. You hoist the Zero. Initially, you have to foot off 15 or so degrees to fill it, get the power in the boat and this, in turn, heels the boat more. That allows you to get your crew on the weather side. The boat speeds up. Now you may be doing 5.5 knots or more and your apparent wind is increasing. This allows you to put the bow up a bit and pretty soon you are nearly doing the same course as before you set the zero, but at maybe 30% more boat speed. This is why virtually every competitive racing boat that sails offshore has a code zero in its inventory.

"Most IRC yachts are rated with three or four spinnakers so choosing which sails to carry for offshore races can be an issue"

Most IRC yachts are rated with 3 or 4 spinnakers so choosing which sails to carry for offshore races can be an issue. Generally, most yachts will include a Code Zero, if they have one, if the wind strength is looking lightish. If it is looking like a windy race, perhaps a small asymmetric might be selected in its place.

For boats over 35 feet, you need a top-down furling system, this is to reduce the load on the furling line when you are furling and it also gives you a very tight furl.

Top-down furling means (above) the tack of the sail is attached to the floating swivel in the furler, so the cable turns and the tack stays still until the first bit of the head is taken onto the cable, then the tack takes up when the body of the sail starts to furl in. This tight furl means you can leave the sail hoisted whilst sailing. As you’re just spinning the cable the load on the furling line is only half that of direct furling, so it’s quick and easy to pull. One person can do this easily.

For boats under 35 direct furling is faster and easier as the loads on the sail are a lot less. So you can get the sail furled up easily.

The tack of the sail is attached directly to the cable (above), so when the cable spins the sail is furled directly onto it. Note with this system you’re spinning the top and bottom of the sail at the same time. The body of the sail as its fuller doesn't furl up as tightly as the top-down system. This is the main difference between the two systems.

In this video (below) you can see a top-down furling gennaker.

You can see the head of the sail furling onto the cable while the tack stays free. So the main body of the sail is furled up giving a tight furl on the cable.

In the second video (below) you can see the tack stays still until the body is on the sail is on the cable and then the tack takes up.

Now the difference for direct furling is in (above), you can see the tack and the head of the sail furl right away. Its faster for a smaller boat to do it this way. But the furl is a lot thicker and not as clean.

With a top-down furling code zero you will never get a twist in the system. As it will just back out the way it went in.

"With a top-down furling code zero you will never get a twist in the system"

The cable and the furler you use in these systems are the most important part of the system. Some furlers can cost more than the sail. They may also not do what they say they can do. It’s always best to buy a furler that has a top-down option on it so your furler can do top-down and direct furling.

The best value for money is the Ubi Maior furler. This furler comes with a ratchet lock and top-down option. The ratchet lock means you can stop the furler, open and close the furl at any point with the quick and easy ratchet trigger.

The cable has to be a torsion cable. Now there are lots of these on the market. Only 10% of these do what they say on the box. Most are just ropes that are called torsion cables.

If you turn the cable at the bottom then the top should turn at the same time. This is an anti-torsion cable. We normally recommend Hampidhan Dynex Pro Furling cable. This is great value and does exactly what it says on the box. If you turn the bottom and the top is furling there and then there is no slack in the system.

Halyard tension is a common question. How much tension does the cable need to furl? With a proper cable then you can use it with low or high tension. If you’re using a rope cable then it needs to be bar tight for the system to work. For example, if it’s not tight then the cable can twist and tear the sail. With a Hampidhan Dynex Pro Furling cable, for example, you can have the halyard soft or hard and still furl the sail away without any issue.

The furling line I normally like to have it in a colour that you can see in the dark, a bright colour is always good for night racing. For racing boats the furling line comes to the shrouds or the mast and is stored out of the way.

When racing I leave the code zero plugged in before the start of the race. So the furler and sheet is on the sail clipped on the bow and the sail is stored down the hatch ready to go so you just need to attach the halyard. It's best to hoist the sail before you leave the dock get the lines set up and cleared away ready for the set. You always hoist and drop the sail on the windward side using the headsail to get the sail up and out into the air.

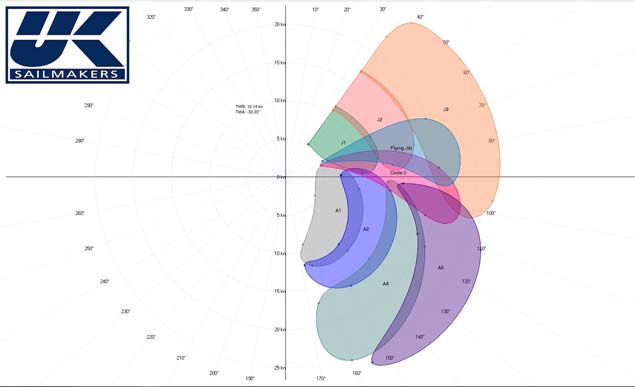

Below is a good example of the polar angles of the Code zero.

You can see the working angles of the Code zero and what it can do for your boat. It totally takes over when you are reaching and gives you the power you need. For overlapping boats then the chart is different the code zero becomes less useful as a working sail.

One of the great uses of the code zero is at night or offshore when you are racing. It’s an excellent tool when it’s too windy to hoist the kite. When you broach out you just furl the sail up and get back on the road.

Cruising

For cruising boats, this is an easy to use great power cruising sail. You can pull it out when it’s light and get the power you need. It’s easy to hoist and furl. You can use your electric winch to furl the sail as well. The same comes in a handy, ready to use bag, so it’s a plug and play sail.

All of the above details, like the cable and furler, still apply and it’s used exactly the same as a racing boat. The only difference is that it has a cruising size roach with 65 % leech hollow.

The sail is perfect for long passages and night cruising passages, when its’ not in use, you can leave it hoisted and unfurl it when you like. You can also add lightweight UV cover onto the leech of the sail and leave it up when not in use short term.

The angles of use for a cruising sail are a little more open as the sail has a hollow leech.

I normally hoist it on the dock and leave it up for the day when I am sailing and use it when it’s needed.

The working angles are from 60 to 120 degrees.

Barry Hayes is a sail designer and product development manager and owner of UK Sailmakers Ireland. He is a member of the Board of Directors UK Sailmakers International

Great Weekend for UK Sails in Scotland & Howth

The performance of the UK Sails Ireland team continues to bear fruit, most recently on the competitive race courses of Scotland and Howth last weekend.

In Howth, at the 1720 Europeans, a UK sails 1,2,4 showed the competitiveness of the UK product range. Congratulations to Aoife English and Ross McDonald who sailed Atara to a well-deserved win, followed by Rob O'Leary on Dutch Gold.

The 1720 class over the last 20–years has been a test–bed for sailmakers to show what their latest and greatest technology can do. In the early days, there were up to 70 1720’s competing and development in the shapes and designs has continuously evolved. Designs perfected in this type of hotbed one design transfer then to mainstream Cruiser and IRC shapes.

Over the last three years, UK sails have won every 1720 Europeans title and have also taken second and third in these events showing their dominance in this hotly contested class.

At the Scottish Series last weekend, UK Sails Ireland were delighted with a class win in class 3 IRC for Samurai J the J92 of Alan MacLeod & Andy Knowles. They were flying a UK Sails provided X Drive jib and a mainsail recut in the UK loft in Cork over the winter, to finish ahead of Howth Half–Tonner, Harmony.

In Class RC 35, Brian and John Hall's J109 Something Else from the National Yacht Club, using UK Ireland sails, finished a creditable second to the overall winner, David Kelly's Storm, in this competitive class. They were, in fact, leading after the first day and in the nine races sailed, Something Else finished ahead of Storm in four races. This was all the more laudable when you consider Something Else was using a non-overlapping headsail on a furler.

UK sails will have its full team at this weekend's Wave Regatta in Howth supporting its clients in whatever way possible including on-site repairs. Barry Hayes, Graham Curran and Claire Hayes from the UK Ireland loft will be in attendance.

Mark Mansfield, UK Sails agent and racing Consultant will also be at Wave Regatta.

Both Curran and Mansfield both leave Wave Regatta to take part in the 2018 IRC European Championships being held in Cowes the following weekend. Curran will be trimming aboard Rob Mc Connell's (UK sails Powered) A 35, Fools Gold, which was the overall winner of the 2017 Sovereigns Week. Fools Gold then goes on to Compete in the IRC Worlds in the Hague in Holland in August.

Barry Hayes leaves Wave Regatta for Holland to Sail trial Uk sails Ireland provided sails for the brand New designed Waarship 36. This innovative new design has been built particularly to try and win the 2018 IRC Worlds in the Hague, Holland and will sport UK Uni Titanium Jibs and Mains and UK Spinnakers.

Waarship 36 –powered by Uk sails Ireland Uni Titanium upwind sails and SK75 spinnakers

Waarship 36 –powered by Uk sails Ireland Uni Titanium upwind sails and SK75 spinnakers

Immediately after Wave, Mansfield will sail in the IRC Europeans in Cowes as Tactician on John Smart's J109, Jukebox, Then moves on a few days later to do the same role on Paul Gibbons Quarter Tonner, Anchor Challenge at the Quarter Ton Cup in Cowes, then a few days later joins Paul O'Higgins JPK Rockabill VI in the Round Ireland race. Rockabill VI includes UK sails in her inventory this year.

UK Sails Ireland will also be providing Back up service in July at Cork Week which is home to the Uk Sails Ireland Loft.

Sailing Professional Mark Mansfield, who is a Racing Consultant with UK Sailmakers Ireland, goes through the different spinnaker sail options and how to set and control each of them. This is the latest in a series of information articles produced in conjunction with Irish Cruiser Racing Association (ICRA).

Up to about 15 years ago it was all very simple when you got around the top mark. You set your spinnaker. If it was windy, you likely had a heavy spinnaker with heavier cloth. You might even have had a reaching version if you had a fancy boat.

Now, that has all moved on. Spinnaker technology has completely changed, especially with the continued development of asymmetric spinnakers. These type of sails came from newer, faster planning boats, where it was found that the more closed leech symmetrical ('normal') spinnakers did not allow the boats to get up and plane easily.

However, asymmetric spinnakers are no longer all about planing. For cruisers, it was discovered that an asymmetric spinnaker on a sprit was easier to gybe, requiring less crew and also was particularly well rated on IRC. Yacht manufacturers like J boats jumped on that early and now virtually all J boat designs have sprits and asymmetric spinnakers, and do very well in racing.

Article author Mark Mansfield (red hat) trimming an asymmetric spinnaker on a J109 in the 2017 Dun Laoghaire Regatta. Photo: Afloat.ie

Article author Mark Mansfield (red hat) trimming an asymmetric spinnaker on a J109 in the 2017 Dun Laoghaire Regatta. Photo: Afloat.ie

The J109 is an example of this. It uses only asymmetric spinnakers and these are very well suited for the design and as a result it wins regularly on IRC and in Ireland attracts great sailing with over 15 in the country presently.

What are the Spinnaker Options?

People are always getting confused by what spinnaker they need and the designation for it. You Hear of an A2, an S4 a Code 0. Many ask what do these stand for? The graph below explains this.

Asymmetric Spinnakers Designations

Code 0—Ultra reaching light air Asymmetric

1A Light Air Reaching Asymmetrical

2A Light Air Running Asymmetrical

3A Heavy Air Reaching Asymmetrical

4A Heavy Air Running Asymmetrical

5A Extreme Wind Asymmetrical

The code zero is a new addition in recent years. On IRC it rates as a spinnaker as its mid girth is over 75% of its foot. However, these are nearly genoa like shapes and are used for light air reaching, where a normal spinnaker could not be hoisted as the wind is too far ahead. So instead of reaching with your jib, you hoist this sail, which is likely at least twice as large as your Jib. Code 0 designs have moved on a lot in. Recent years and instead of the Old code 0’s which had flappy leeches, the new Code 0’s are much more efficient.

George Sisk's Farr 42 Wow with her new UK sails A 2 spinnaker projected to windward—tack line off a touch Photo: Afloat.ie

George Sisk's Farr 42 Wow with her new UK sails A 2 spinnaker projected to windward—tack line off a touch Photo: Afloat.ie

Symmetric Spinnakers--Designations

1S Light Air Reaching Symmetrical

2S Light Air Running Symmetrical

3S Heavy Air Reaching Symmetrical

4S Heavy Air Running Symmetrical

5S Extreme Air Symmetrical

Paul O Higgins JPK 10.80 Rockabill V1 with her new UK sails S2 Symmetrical Spinnaker Photo: Afloat.ie

Paul O Higgins JPK 10.80 Rockabill V1 with her new UK sails S2 Symmetrical Spinnaker Photo: Afloat.ie

How to Set & Trim your Spinnaker

Asymmetric Spinnakers – Setting an Asymmetric spinnaker is pretty straightforward. First get the tack to the end of the sprit/bowsprit. If you have a mechanism like we have on UK sails asymmetrics, where there is a shockchord band built into the luffs, use this to stop the tack opening too early.

When the hoist is called, a quick bear off of the helm, bounce the chute up quickly, and even before it hits the top, the jib halyard should be released so that it drops a few metres initially. This then allows the head of the Asymmetric to fill quickly which drags the rest of the Asymmetric forward and it normally fills with a big whoosh. It is important that the sheet is allowed to spill out quickly until the moment that it just starts to curl, as without a quick spill, the boat is liable to become overpowered and round up. Once filled, the first thing I always ask is for the Other Spinnaker sheet to be loaded immediately on the other winch so that if I opt for a very early gybe, we are immediately ready. This is very important as often after rounding a top mark, it can get very crowded to weather with boats trying to go over the top of you and sometimes a quick gybe can be completed and you can exit the pack easily.

Gybing an Asymmetric—inside Ensure you take in all the slack on your lazy sheet. As the boat goes into the gybe ease the old sheet, but do not let it go completely as the clew will get too far forward and then when you gybe it can easily twist. Best to hold the sheet until you feel the pressure coming on the new sheet. Normally one or two crew will manhandle the new sheet around the front of the forestay. The sheet trimmer will need to sheet on a good bit initially, then when it fills, a big release is necessary to get it out.

Gybing an Asymmetric—outside This is the best way if your sprit is quite short, as there may not be enough room to get it across between the forestay and the chute. It is slower however and if an inside gybe can be achieved, it is normally a better way to go. With an outside gybe, you just let the sheet go completely and flag the sail out in front. Then, when the boat is passed dead downwind, the new sheet is brought in. There will be a lot of sheet to come in though, and this can take some seconds where the spinnaker will not be filling. It is the best option if you are short crewed and in much bigger boats it is a safer bet with less chance of a wrap.

Trimming an Asymmetric

Running with an Asymmetric is quite difficult as if it is too deep, the spinnaker gets into the bad air of the main and collapses. It is important to try and get the spinnaker projected to windward and steady. Positioning your crew up by the shrouds, to windward will help this projection, as will a release of the tackline. My guide to how much tackline to release is to initially ease the tackline quite a lot, then wind it back in, while the trimmer keeps trimming the chute. The asymmetric spinnaker should rotate to windward as the tackline comes on, then there will come a point where it stops rotating to windward and goes the other way. That is normally when the tackline is in the correct position—just when it tries to go the wrong way.

Unlike a symmetric spinnaker, it is best not to have a permanent curl on the luff. I find that you always need to be trying to ease the sheet and when it curls, take the curl out. Very often you see a curl, you pull in one foot of sheet and the curl disappears, then you can release about four feet quickly till it curls again, then a foot back in. It must be a constant thing, happening all the time.

Likewise, the trimmer must be talking constantly to the helm. The trimmer, I often say, drives the boat downwind, the helm just turns the wheel and does what he is told. The trimmer needs to sense when the pressure is strong immediately and call the helm to bear away. Likewise if his sheet is getting slack, he must call the helm up. Getting deep downwind is an art and the trimmer is the artist. A quiet trimmer is rarely a good trimmer.

Jackhammer, the new J121 with her Uk sails Ireland code 0 showing how it can be carried up the wind range and sheeted very close

Jackhammer, the new J121 with her Uk sails Ireland code 0 showing how it can be carried up the wind range and sheeted very close

Dropping an Asymmetric

This can sometimes be a bit exciting, especially if you are reaching into the mark. If at all possible drop the spinnaker on what will be the new leeward side on the next hoist. Changing the gear from one side to another, while going upwind is very slow. Sometimes however , especially if coming in on a tight reach, there is no choice—you have to do a Leeward drop. This is generally to be avoided if possible as it is much more likely that you will put the chute in the water on a leeward drop.

It is much better to try and arrange your gybes to come in and be able to do a windward drop. With a windward drop, just get one or two crew all set up on the weather lazy sheet, make sure they are right back towards the shrouds as you want to get as much of the sail around the forestay as possible. Dump the tack line, pole out and spinnaker sheet at the same moment which should allow the spinnaker to flag easily out the front, then pull the windward sheet hard and make sure to get all the foot in quickly. Then down the hatch.

A leeward drop is a lot more difficult. It is best to have a retrieval line attached to the tack. This goes under the jib and above the lifelines. Have 2 crew braced and ready to pull this. Dump the pole, then throw some halyard and release the sheet at the same moment. The spinnaker should collapse, then the two braced people have to pull like mad to get it out of the water. The tackline is dumped at this juncture and the halyard is held until you see it in control, then progressively eased. Not for the fainthearted and this option should be avoided if at all possible.

Finally, there is a Mexican drop (sometimes called a Kiwi), where you are gybing at the bottom mark. The trick here is a wide rounding, a slow gybe, hold the spinnaker sheet tight on the leeward side until you gybe, then just leave the spinnaker collapse into the spreaders as you gybe(slowly, hopefully), then the halyard goes fully and the spinnaker is dragged down the windward side. It might sound complicated but it can be the safest choice to ensure it does not go in the water.

Symmetric spinnakers

Hoisting – Similar to an asymmetric, just set the pole up before you round, get deepish quickly, get the poll back early. Try and preset the sheet to a mark, so that when you hoist and bear off it fills immediately. Again, always we set up immediately for a gybe.

Trimming – Running downwind the clews should be level, However, often it is best to choke down the sheet to leeward to keep the spinnaker from skying. Once this is done, then the pole may not have to be raised on the outboard end too much. Always have the pole level to ensure max projection.

The weather luff should not over rotate too much over the line of the end of the pole. If you do, that will actually make the projected area smaller. Better to pull the pole aft as much as you can, keeping the weather luff nearly parallel to the mast, easing the sheet regularly but not so much that it rolls over itself.

When you gybe, try and get all the crew to move their weight to windward just as you gybe, that heels the boat to windward, helps the boat to bear off without a lot of helm movement. Then, once the main swings through, all the crew jump to windward, and this rocks the boat through the gybe. Also if the boat ends up then heeled to windward that keeps the spinnaker out on that side, until the pole is sorted. As a practice move, I often take off the pole altogether and the crew go through a series of gybes without a pole, using body weight to help the spinnaker move from one side to the other.

In strong winds, dead downwind, it is best to ease the pole a bit forward and overtrim the sheet to keep the spinnaker from swaying around. This will help the control. Also pull in the mainsheet a bit to prevent the Chinese type windward broach which is never pretty.

Rob Mc Connell's Fools Gold with her UK sails S2 spinnaker and Uni Titanium Main, on the way to winning Sovereigns week 2017

Rob Mc Connell's Fools Gold with her UK sails S2 spinnaker and Uni Titanium Main, on the way to winning Sovereigns week 2017

Is it best to go Asymmetric/Symmetric?

Faster, planing boats will always go asymmetric, as they can maybe double in speed when they plane, and it is easier to get on the plane with an asymmetric. With slower, displacement boats it is a more difficult choice.

You can, of course, have a combination of both, have symmetric sails for running, and Asymmetric sails for reaching. However, an Asymmetric sail sets best on a prod and if you have both a pole and a prod, the prod can't be any longer than the distance the pole extends out over the pulpit (STL measurement on IRC), unless you want to extend your STL at the cost of your rating. Most boats with symmetrical spinnakers who are competitive, will have at least one asymmetric spinnaker as well, normally an A3 for reaching.

The IRC rule gives an advantage in rating to a sprit only boat, as that boat is unable to pull back the sprit like you could with a symmetrical pole. As a result, for the same rating, you normally can get approximately 10% to 15% more spinnaker area with a sprit only boat. In light airs, when a boat with a pole has to heat up anyway and have the pole close to the forestay, then the sprit boat can go at the same angle and have maybe 15% more sail. Clearly, a win for the sprit boat. In medium winds, up to about 15 knots, the sprit boats, setting a nicely set modern asymmetrical A2 chute, can likely match a symmetrical boat downwind, as it can't go as deep, but it has more sail area. Above 15 knots, the poled out symmetrical boats come into their own, they can go virtually dead downwind, whereas the asymmetrical boats still have to stay maybe 15 degrees off dead downwind as if they go too deep, the asymmetric, sometimes in a second, just collapses as it gets bad wind from the mainsail.

Offshore though, the asymmetric finds a lot of favour, as unlike windward/Leeward racing, offshore racing often has a lot of reaching, and with the extra sail area that an asymmetric boat can carry for free, it has a great advantage reaching. Often you will see competitive boats completely change to a sprit mode for a race like the Round Ireland or Fastnet and then change their rating back to a symmetrical setup for inshore racing. It needs a lot of sails and a big bank account for that though as the spinnaker sizings would be different.

Crewing an asymmetrical boat is easier, especially handling the spinnakers. A symmetrical set up needs a very good bowman, otherwise there is real trouble in store. I am sure most of the good asymmetrical boats also have very good bowman, but even some inexperienced bowman on a sprit boat can get away with most hoists and drops.

There maybe a lot of choices nowadays and it can all be a bit confusing, but there is no doubt that having the right inventory of downwind sails will bring a big advantage.

All the best and fair sailing.

Mark Mansfield

Racing Consultant /Agent for UK sails Ireland

Ph 087 2506838

E mail—[email protected]

Other articles in the UK Sailmakers Ireland/ICRA 'How to...' Series:

Introducing The UK Sailmakers Ireland 'How To' Article Series

Sailmaking Tips & Tricks: Battens, Furling & Caring for Sails

Tuning a Fractional Mast & Rig

Changing Gears in Different Wind Conditions

Downwind Sails—What Are The Options?

Sail Design: Where Are We Now?

Rig Tuning—Adjusting Mast & Rigging in Different Wind Conditions

Royal Irish Yacht Club Skipper George Sisk has had the Farr 42 WOW! for nearly ten years so there was a feeling that it was time to look at a new boat for his Dublin Bay and Irish yacht racing campaigns. But WOW! has been a great boat for him over the years. In particular in 2015, when he won both the ICRA Nationals in Kinsale and also won his class and overall at Dun Laoghaire Regatta. These outstanding results culminated in the ICRA Boat of the Year accolade for 2015.

George briefly flirted with a J111 but the draw of the Farr 42 was never far away. So a decision was made at the end of 2017 to see if WOW! could be brought more up to date, improve areas of weakness and see if she could live with some of the fancy new kit coming out these days. Mark Mansfield of UK Sailmakers Ireland reports on these latest developments.

A team of 'knowledgeable heads' looked at the boat to see what could be done. These included George and some of his key crew, the Farr Design office and Barry Hayes from UK Ireland Sailmakers. Some areas for improvement were identified:

- WOW! was a bit slow out of tacks and a bit difficult to keep in the groove. A decision was made that a more IRC friendly fin keel would be a better option to the fin and torpedo that she had. This deeper more straightforward keel was relatively rating neutral.

- WOW!'s asymmetric spinnakers were too tall and not wide enough due to her having masthead spinnakers. With the size of chute that was best on IRC, it was felt that a lower halyard exit would allow her spinnakers to be less tubular and a better, more correct shape. Barry Hayes then designed her new downwind sail wardrobe with this change in mind. The results, shown in the photograph below, are evident. The asymmetric sail now floats perfectly to windward and sits there allowing WOW! to sail deep and fast, with less sheet movement. Also her new Code 0 can now have a fully taught luff to allow the sail to be used to its best advantage, due to the lowering of the halyard exit and also because of the advances in sail technology. This Code 0 utilises a top down Ubi Maior furler, which has a cable in the luff allowing it to be furled and deployed easily.

WOW! with George Sisk on the helm showing off her new UK Sails Uni Titanium moulded mainsail and A2 running spinnaker Photo: Afloat.ie

WOW! with George Sisk on the helm showing off her new UK Sails Uni Titanium moulded mainsail and A2 running spinnaker Photo: Afloat.ie

The next identified area for improvement was gybing the main in strong winds. The solution was a new pair of electrically operated winches, Organised again through Barry Hayes in UK Sailmakers through their Harken winch and hardware agency, so that the main could easily and quickly be centralised.

"a solution to improve gybing the mainsail in strong winds was a new pair of electrically operated winches"

Only time will tell if these changes will make a difference. A new suit of UK Uni Titanium–Grand Prix Molded upwind sails was also selected, taking advantage of technology changes over the past few years.

WOW! with her UK Sails Uni Titanium Molded main and J2 Jib Photo: Afloat.ie

WOW! with her UK Sails Uni Titanium Molded main and J2 Jib Photo: Afloat.ie

Initial testing in Dublin Bay last weekend was very promising as WOW! blasted around the DBSC course. Barry Hayes and I were on hand to initially set up the rig and then to assist in the sail trials followed by competing in the DBSC race.

The sailing plan for WOW! is still being finalised for this year and may include some or all of: the Round Ireland Race, Cork Week and Wave Regatta. What will happen for sure is WOW! will, as she has always done, be a regular competitor in the DBSC series in Dublin bay, which is a firm favourite for George and his crew.

Since Des McWilliam retired and sold the UK Sails business to Barry Hayes and Graham Curran at the end of the year, they have lost no time in getting their new designed products out to their customers. In addition they have brought in the knowledge of Mark Mansfield, the four time Olympian and professional sailor, to work with them as an agent and racing consultant.

Results are already showing with the season only just started. In the first of the 2018 ISORA Races, the Welsh ISORA race was won overall by Andrew Hall's, J125 Jackknife, sporting UK Ireland sails, and winning by a considerable margin. Andrew has also just purchased one of the new J121 speedsters which also sports a full suit of UK Ireland sails, the subject of a recent article on Afloat.ie here

Andrew Hall's, J125 Jackknife

Andrew Hall's, J125 Jackknife

On the same day, the first ISORA race was run on Dublin Bay and the winner of Class 1 was Roger Smith's Wakey Wakey from Poolbeg Yacht & Boat Club, which included, in her sail inventory, the new UK sails J1 – JX Jib which was tested here in Dublin recently here

First DBSC Races

More recently, last weekend's first DBSC weekend race featured Uk sails winners in Both Class 0 IRC and Class 1 IRC. In Class 0, Paul O'Higgins JPK 10.80, Rockabill VI, won sporting new A 1.5 and S2 spinnakers from UK sailmakers. In class 1, John and Brian Halls’ J109, Something Else, showed good speed with her UK Sails inventory to win Class 1.

Kinsale Spring League

In Kinsale, KYC's Spring League, as featured here with photo gallery, finished up last Sunday with an emphatic win for Kieran Collins Olsen 30, Ocacle IV, in IRC Class 2, with straight wins, sporting a new X Drive main and Jib and Spinnaker from UK Sailmakers. This was an impressive result as in their class was also Finbarr O'Regan's well sailed Artful Dodger, an Elan 333, which won its class at Sovereigns Week in 2017.

Kieran Collins Olsen 30, Ocacle IV Photo: Bob Bateman

Kieran Collins Olsen 30, Ocacle IV Photo: Bob Bateman

Warsash Spring Championships

Further afield, Mansfield was Tactician and Mainsheet on John Smarts’ J109, Jukebox, which won the Warsash Spring Championships which was an 11 race series run over two weekends in the Solent, which finished last Sunday. Mark Will be Tactician on Jukebox, when she competes in the upcoming IRC Europeans being held in Cowes in June, in conjunction with the Commodores Cup. Included in the fleet for that event will be Rob McConnell's Fools Gold, winner of last year Class in Sovereigns Cup and the Welsh IRC Nationals. Fools Gold also sports a full UK sails Inventory, and trimming on that boat will be Graham Curran of the loft.

This weekend sees all 3 UK sails people (Barry Hayes, Graham Curran and Mark Mansfield) performing sail trials on a number of clients yachts in Dun Laoghaire who have opted for the new technology and expertise that the new UK Ireland Sails team are bringing to the market.

In his first article in the ICRA / UK Sailmakers Series, Racing Consultant Mark Mansfield wrote about tuning a fractionally rigged mast. His second article featured changing gears in different wind conditions while racing. In this final article, the four time Olympic helmsman covers how to adjust your mast for varying wind conditions.

The sailing season is upon us, boats are starting to race and many are just in the process of trying to set up their masts, tune the rigs as best they can, and get themselves into a good position. I have already done six full rig tunes on various boats with another four planned for next weekend. Now is the time to go through the process of how to get your mast set up correctly.

In my first article, tuning a fractionally rigged mast, I went through how to set the mast up for base (10 to 15 knots) conditions.

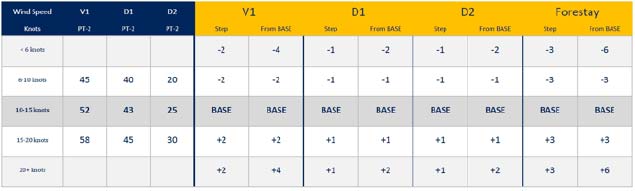

In my second article, I went through how to adjust your sails in varying conditions, using mainly your backstay, mainsheet, traveller and Jib track to get the best out of the sails. In most racing boats, the shrouds and forestay will be pinned with rigging pins, and the adjustments I described in my second article will be what they will do. However at the top end, this is not really enough and you will likely find that the top performers will also adjust their standing rigging (shrouds and forestay) every five knots of wind or so, and likely will end up with a tuning guide, with five different settings. If you look at the J109 Tuning Guide (below) that we have developed, you will see adjustments being made to your rig, every five knots or so.

Some more modern racing boats may have a mast jack, which is a really nice thing to have as you can leave the shrouds as they are and easily soften and tighten the rigging by jacking up the mast (or down). Most boats, however, will have bottlescrews and making adjustments takes more time.

Lighter Wind Rig Changes

So why do you do this? In medium base winds (10 to 15 Knots), the sails should look great by just pulling them in, putting a liitle backstay on and off and away you go. The sails are cut to be good in these conditions without much adjustments required. That is why often you can find less experienced sailors up the front in these conditions. However, say the wind goes down to 7 knots, you leave off your backstay, you will have to ease your mainsheet as the leech tension will still keep the forestay straight. Even with this, you may find that the jib is still not developing enough power, as the forestay is still too firm. Also you may now find the main is a bit too full and as a result you cannot put a lot of mainsheet on as the top closes too quickly. The helm may feel a bit dead and you are starting to put crew down to leeward to try and provide more heel in order to in turn provide some feel on the helm.

Top performers adjust their standing rigging (shrouds and forestay) for every five knots of wind

The reality is, in these conditions, the shrouds and forestay should be eased. Easing the outer shroud (cap) will loosen the forestay and this forestay sag will provide power. If you loosen the outer, then the other shrouds will need to be eased, as otherwise the lowers and diagonals will hold the mast too straight. This is because the outer shroud compresses the mast and forces prebend into it, and loosening it allows it to straighten. Taking a few turns off the forestay also allows the mast to come aft a bit which adds rake and should give the helm more feel.

In very light airs, you loosen even further, for the same reasons.

REMEMBER, IN MOST CLASSES, INC. IRC CLASSES, IT IS NOT ALLOWED TO ADJUST YOUR STANDING RIGGING WHILE RACING (AFTER FOUR MINUTE GUN). ADJUSTMENTS MUST BE MADE BEFORE YOU START RACING.

Stronger Wind Rig Adjustments

Looking at the Tuning Guide above, You will see the exact opposite will happen when the wind is getting stronger. The shrouds and forestay will need to be tightened. This is because, once you go over 15 knots, you are needing to depower. The first and best way to depower, is using backstay, which will straighten your forestay. Once over 15 knots a straight forestay is very important for pointing and also to balance the helm. If the forestay is anyway saggy, too much power will develop.

However to straighten the forestay using backstay there is normally a problem . If your mainsail is cut correctly, then as you progressively harden the backstay, your mainsail should eventually become overflat in the middle, as the backstay will bend the mast too much and take the fullness out. This will be evident when you get overbend wrinkles from the clew of the main up to the middle of the mast.

Some boats may not get these overbend wrinkles and that is either because they have a treetrunk of a mast (which is not good) or they may have a very full mainsail anyway and adding extra mast bend just takes some of this out. That’s all very well, but I would expect that a mainsail like this will be completely too full in lighter airs. If the main is not over bending in stronger winds, that is an indication that is needs some luff curve taken out of it by your sailmaker to make it more balanced in all conditions.

It is very rare that a mainsail can look fantastic in light, medium and strong wind conditions. As a general rule you design a main, for Irish conditions, to be best in moderate winds and you then either live with it in the other conditions or you adjust the rig to try and get the rig to fit the sail in those light and heavy conditions Photo: Bob Bateman

It is very rare that a mainsail can look fantastic in light, medium and strong wind conditions. As a general rule you design a main, for Irish conditions, to be best in moderate winds and you then either live with it in the other conditions or you adjust the rig to try and get the rig to fit the sail in those light and heavy conditions Photo: Bob Bateman

In addition, a correctly cut mainsail luffcurve means, as you take on Lower and intermediate shroud tension,( in order to keep the mast from overbending), this also stops the mast from sagging to leeward in stronger winds which would close the slot. If your main is cut too full, then easing the lowers is what you might want to do to depower it a bit, but this then allows it to sag to leeward.

As a general rule, the middle of the mast should sag a little to leeward in lighter air as this will develop power. Once you have enough power with all the crew on the side, backstay on and maybe the traveller down a bit then it should be straight sideways. In stronger winds a bit of windward bend in the middle is fine. The reality is, especially with Aluminum masts, in stronger airs the tip of the mast will fall off a bit to leeward which will assist in pushing the middle to windward. Try and have a regular curve if you can. S Bends are slow.

Tightening your forestay will initially reduce your prebend a little, but when you then tighten your Backstay, that prebend will get back to where you want it.

Jib Adjustments in These Varying Conditions

In medium winds, you are looking to have your jib reasonably flat at the bottom, with the leech still slightly open up top. Your halyard tension should not be too hard and if the sail is cut correctly, very small wrinkles will be evident in the luff with the draft (max depth) showing at about 40% from the front. Overtightening the halyard in these condition will move the draft too far forward and flatten the sail. It is very important to get marks on your Halyard to ensure you don’t overtighten. Tying your headsail on with a bowline is no good if you are trying to reproduce halyard tension positions, so best to use a snapshackle or a soft shackle (rope loop—modern option).

As the breeze increases and the backstay is hardened, which tightens the forestay, the jib track position may need to come back to flatten the Foot, while still keeping the leech reasonably tight. Trying to overly twist the leech is not normally a good way to depower as the balance of the boat gets affected with too much weather helm. It is best normally to keep the Jib nailed in and flatten it on the foot in the breeze. You will normally also end up tightening the halyard as the draft will move too far aft and end up cupping the leech

In lighter air, the opposite is the case with the jib. Move the car forward to make the foot more powerful. Loosen the halyard to show additional wrinkling.

With overlapping genoas (comes outside the shrouds), you are constrained by the length of the spreaders. With these sails, you will normally sheet in the sail until it touches the spreader and then you adjust the car for fullness while still keeping the sail just touching the spreader.

With non overlapping jibs, which is now the popular choice on more modern boats – see Photo of J109 – the jibs never come back around the shrouds. Making a few marks with tape on the bottom of the spreaders is very useful as you will find a mark that works well, then you just wind the sail in after every tack and keep the leech of the jib in line with that mark.

J109s tuning on Dublin Bay. Joker II (right) using UK Sailmakers JX jib mainsail complimented nicely by the test JX jib

J109s tuning on Dublin Bay. Joker II (right) using UK Sailmakers JX jib mainsail complimented nicely by the test JX jib

The modern non overlapping Jib nearly fills the full foretriangle and would be inhauled to bring the sheeting angle in tighter. Very modern boats will inhaul to about 6 degrees, which is extremely tight and the shape of these sails will be cut to allow a bit more twist in the leech so as not to close the slot. A few weeks ago Graham Curren of UK sails did an article showing a new J1 Jib that resulted from an intensive FSI testing and development programme we did on a J109 light jib, This sail was designed to allow this sail sheet to about that 6 degree level. Presently most J109’s can only get to approx. 9 degrees due to the shape and the clew height. This necessitated a very simple adjustment to how the clew height is managed. The results have been very positive.

JEDI's Uni-Titanium mainsail complimented nicely by the test JX jib. Computerised FSI testing is a crucial element of modern sailmaking

JEDI's Uni-Titanium mainsail complimented nicely by the test JX jib. Computerised FSI testing is a crucial element of modern sailmaking

Adjusting the Rig—Simpler Option

In a perfect world, the adjustments shown in the Tuning Guide would be made before a race and indeed in top level big boat racing worldwide this would be done by very capable, maybe Pro crew. They would be used to doing it and indeed the helm would contribute and might even look for changes based on what he is feeling from the tiller(or wheel).

The problems with all these changes is firstly remembering what changes were made recently and secondly ensuring that while tightening bottlescrews regularly, when you mean to take turns on, sometime by mistake turns are left off. That then leads to S bends being created and sometimes a complete retune of the mast is needed if this happens.

There is another option, which gives most of the benefits of all these changes, but by just adjusting one Bottlescrew. That option is just adjusting the forestay, but by more than you would do if you were also doing the shrouds. So, In the case of the J109, instead of loosening the forestay by three turns in the applicable conditions, you loosen it by five turns. Likewise in the heavier conditions you tighten the forestay more than you would by five turns instead of 3. Tightening the forestay also tightens the shrouds and loosening it, loosens the shrouds. As a result you are getting most of the gains (not all) but you are making it easier to do and quicker. Quicker is important as often just before a start sequence, the wind strength changes, and there is not enough time to make so many adjustments. All of this also eliminates the very damaging situation of incorrectly adjusting the shrouds by mistake, as outlined in the previous paragraph.

I have to say, when I sail on boats where I perform a rig tune, often I will just go down the forestay adjusting option myself. It gives most of the gains, is quicker and more reliable.

Thank you for taking the time to read this, and my previous articles. I am a consultant (and Agent) for UK Sailmakers and we are always trying to help sailors get the most out of their boats and sails. I have a specialisation in Tuning Rigs and am available to any owner (whether you use UK sails or not) to do a full rig tune for them or over a day do a combination of a rig tune and some coaching. I can be contacted at [email protected].

Fair winds and enjoy your sailing

Mark Mansfield

Article author Mark Mansfield, Professional Sailor and Racing Consultant for UK Sailmakers Ireland Photo: Afloat.ie

Article author Mark Mansfield, Professional Sailor and Racing Consultant for UK Sailmakers Ireland Photo: Afloat.ie

In addition to being a self employed sailing Consultant for UK Sailmakers Ireland, Mark Mansfield is a Professional Sailor. He has been competing for 35–years on the International stage including four Olympics in the Star Class, four Admirals Cups in the 80’s, Commodores Cups in the last ten years and numerous other One Design and big boat campaigns. He has a specialisation in rig tuning and has tuned many of the top racing yachts in Ireland. He also is a noted tactician and was tactician on boats which have won their class in the last 3 ICRA nationals, the last three Volvo Dun Laoghaire Regattas (incl overall boat in 2017), IRC Europeans winner, Cowes Week winner, Spi Ouest winner, Cork Week, Scottish Series, UK IRC winner etc. He is a two times Irish Sailor of the Year and a two times Irish Helmsmans Champion. He is available to sail with, coach, tune rigs or advise on rating improvements for any boat, whether they use UK sails or not. Contact Mark at [email protected] or mobile: 087 2506838

Other articles in the UK Sailmakers Ireland/ICRA 'How to...' Series:

Introducing The UK Sailmakers Ireland 'How To' Article Series

Sailmaking Tips & Tricks: Battens, Furling & Caring for Sails

Tuning a Fractional Mast & Rig

Changing Gears in Different Wind Conditions

Downwind Sails—What Are The Options?

Sail Design: Where Are We Now?

ISORA's J121 'Jackhammer' Takes Her Maiden Voyage Stateside, Flying UK Sailmakers Ireland Sails

Earlier this month UK Sailmakers Ireland’s Barry Hayes was in Newport, Rhode Island, commissioning sails aboard the new J121 “Jackhammer”.

Owned and campaigned by ISORA and Ocean Racing veteran Andrew Hall – “Jackhammer” has an extensive programme planned for her first year having just been released from the J Boat yard in Rhode Island after an extensive IRC optimisation fit out – starting with June’s Newport to Bermuda race.

Barry was joined by Andrew and his crew for three days of fitting, sailing, and testing in Newport. Sam Hall kindly provided some excellent drone footage of the superb sailing conditions in Newport – although the sun does not quite reflect the ambient temperature of an early April Newport!

'Barry Hayes was joined by Andrew and his crew for three days of fitting, sailing, and testing in Newport'

“We have been working hard on this project for many months this winter” - explains Hayes – “We are very excited to see ‘Jackhammer’ in the water and out sailing. Andrew has put a lot of work into this project and we are delighted to be involved. The UK Sailmakers goal was to provide a turnkey sail package for Andrew. He was able to step aboard, throw off the lines, and go fast straight away – goal achieved.”

Jackhammer was built in the US, the sails were designed in Ireland, built in the UK Sailmakers production facility in Hong Kong, and then fitted and tested in Newport – such is the global reach and expertise of the UK Sailmakers Group.

Jackhammer is powered by Uni-Titanium upwind and an extensive downwind wardrobe consisting of Matrix spinnakers and Top Down furling Code Zero and Flying Jib.

The J121 is designed with ease of use in mind – as such all fore sails are set on furlers. The J1 and J2 jibs work on a Selden Furling unit with the J3 Staysail working on an Ubi Maior furling unit. The J3 is hoisted to a halyard lock and tensioned using a 3:1 purchase tack line – this enables it to be cleared off the bow when not in use but deployed with ease and speed when needed.

The J121 is designed with ease of use in mind – as such all fore sails are set on furlers. The J1 and J2 jibs work on a Selden Furling unit with the J3 Staysail working on an Ubi Maior furling unit. The J3 is hoisted to a halyard lock and tensioned using a 3:1 purchase tack line – this enables it to be cleared off the bow when not in use but deployed with ease and speed when needed.

In addition to her A2 and A3 downwind Matrix Asymmetric spinnakers, Jackhammer is also equipped with a top down furling Code Zero, direct furling Flying Jib and heavy weather direct furling A5 Asymmetric spinnaker. This setup is versatile and enables the power output of the sailplan to be managed very effectively – especially offshore.

In addition to her A2 and A3 downwind Matrix Asymmetric spinnakers, Jackhammer is also equipped with a top down furling Code Zero, direct furling Flying Jib and heavy weather direct furling A5 Asymmetric spinnaker. This setup is versatile and enables the power output of the sailplan to be managed very effectively – especially offshore.

In the video (above) you will see the Flying Jib set on a small bowsprit and used in conjunction with the J3 Staysail. Also shown are her Top Down Furling Code Zero and her J2 and full mainsail configuration.